Plug and container made of film and having plug

A technology of plug mouth and plug cover, which is applied in the field of film-made containers, can solve the problems of easy loss of the plug cover, opening, strong force, etc., and achieves the effect of not easy to lose and preventing the plug from opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

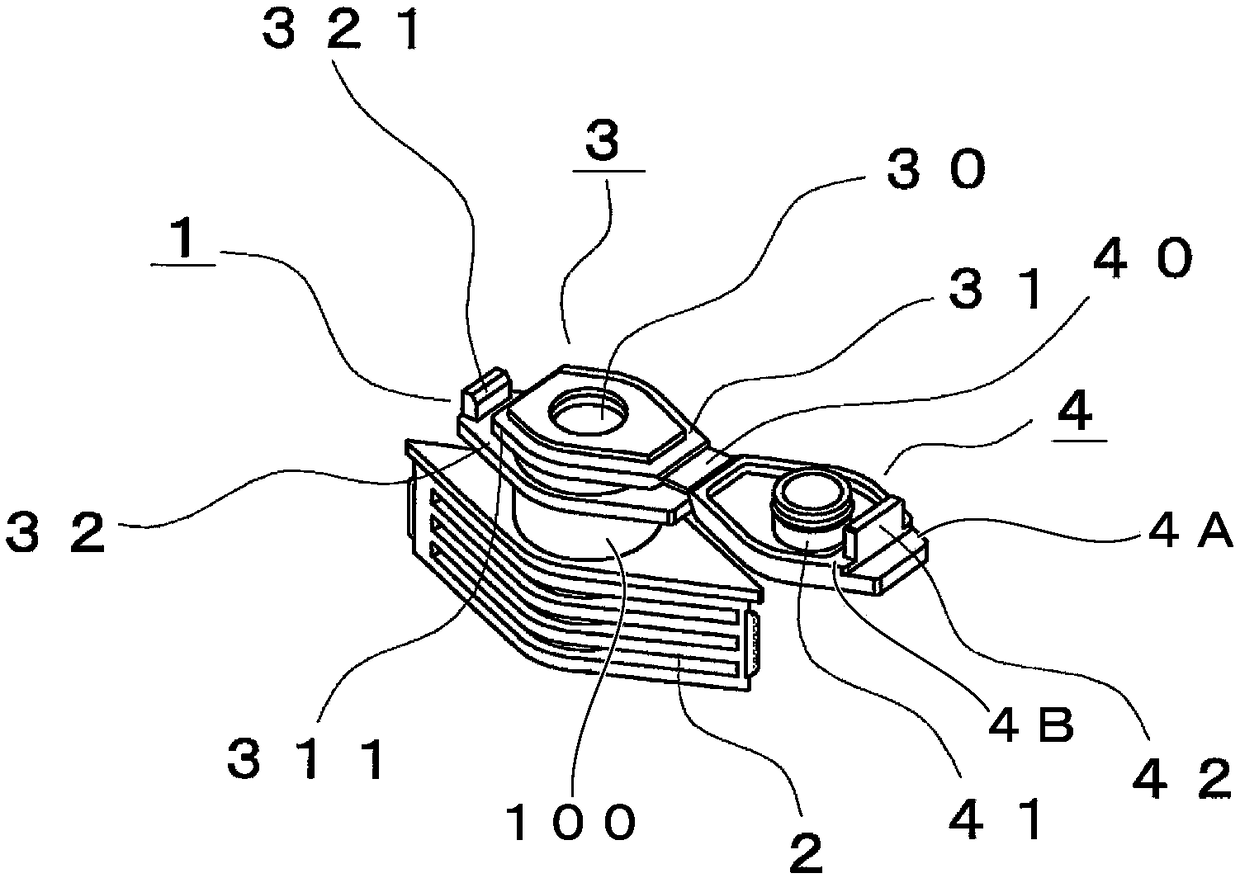

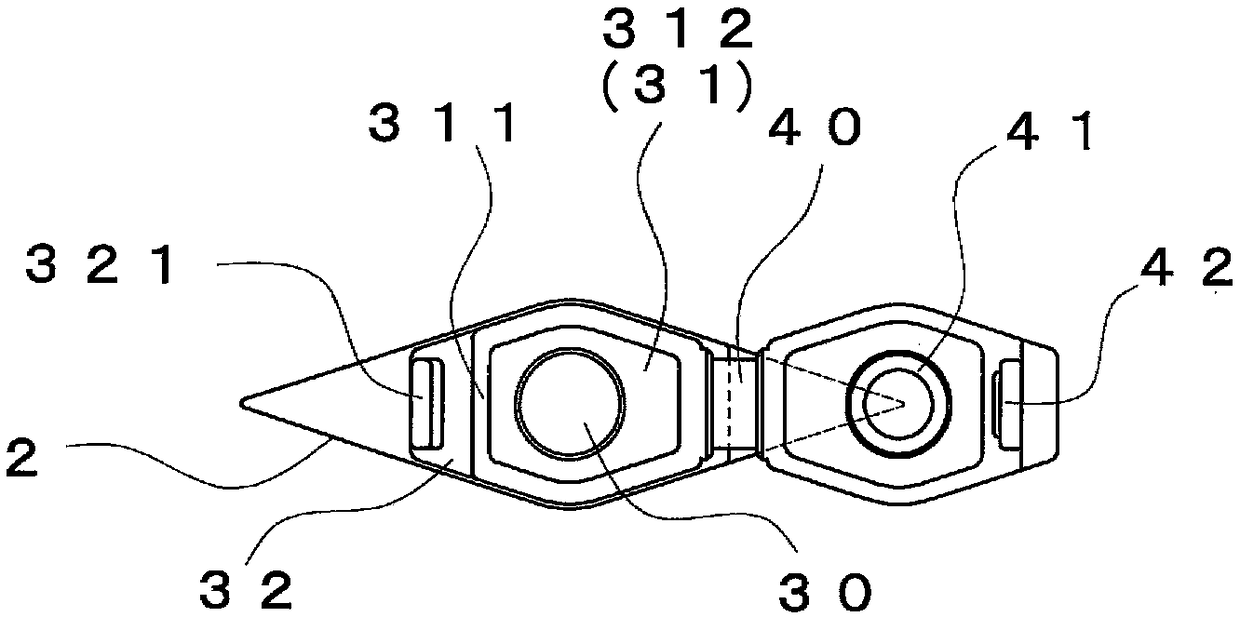

[0059] figure 1 It is a perspective view which shows the appearance of the spout concerning 1st Embodiment of this invention.

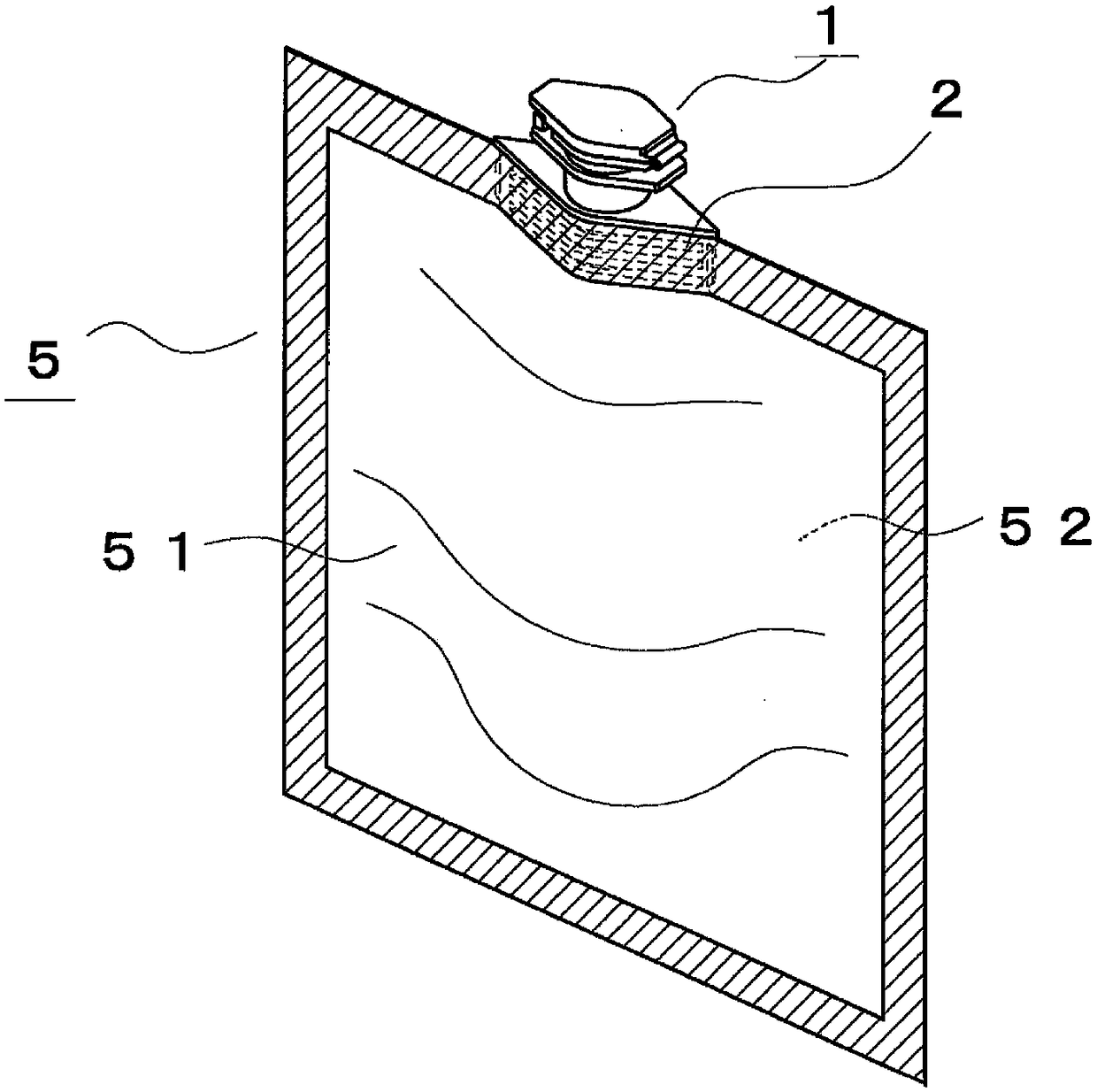

[0060] figure 2 It is a figure which shows the case of using the film container which welded the spout concerning 1st Embodiment of this invention, and is a perspective view which shows the external appearance of a film container.

[0061] Generally, the plug according to the first embodiment of the present invention is injection molded to have figure 1 Manufactured in the shape shown in the perspective view. The spout 1 is used by welding one end of the film-made container 50 . The plug mouth 1 has a welding portion 2 located below the plug mouth 1 . In order to facilitate the welding of the film and the spout 1, the welding part 2 is formed in a boat shape in which the outer shape in the longitudinal direction becomes sharper to the left and right and the center bulges in a circular arc in a plan view. Furthermore, the spout 1 has an outflow o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com