P-chloromethylstyrene/acrylic resin-grafted methylpyridinium nicotinate and novel marine antifouling coating prepared therefrom

A technology of nicotinic acid methyl pyridinium salt and chloromethyl styrene, which is applied in the field of new marine antifouling coatings, can solve the problems of slow enrichment and marine biological hazards, improve bactericidal activity, improve hydrophilicity, and avoid the occurrence of winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] p-Chloromethylstyrene / Butyl Methacrylate Grafted Methyl Nicotinate Pyridinium Salt

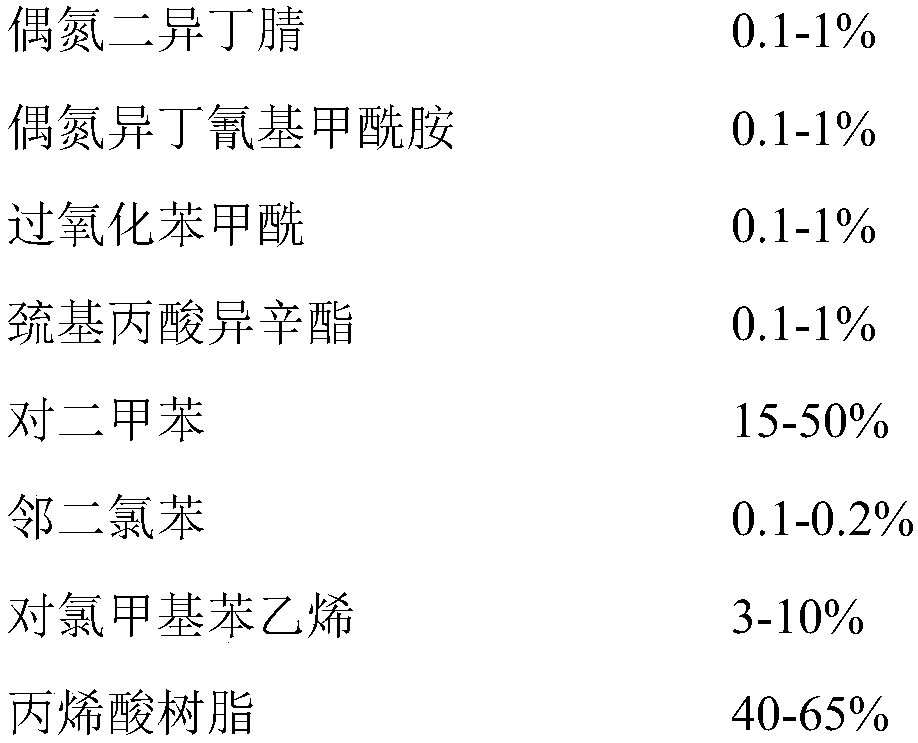

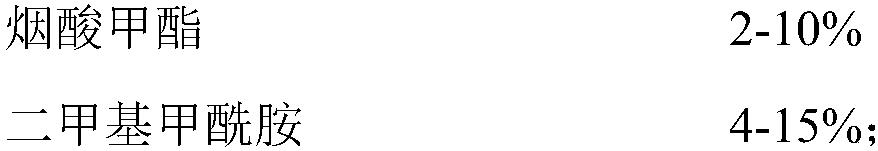

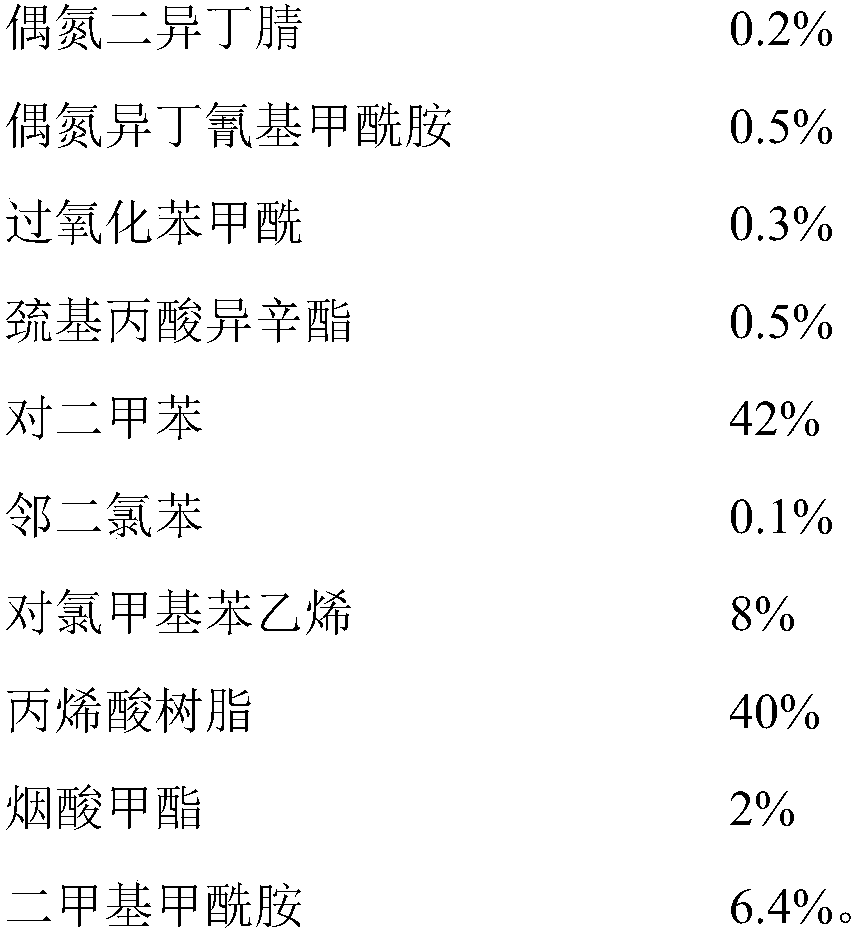

[0040] The reaction material charging capacity is shown in Table 1, and the preparation method comprises the following three steps:

[0041] (1) Add 1 / 3 of the recipe amount of azobisisobutyronitrile, and the recipe amount of isooctyl mercaptopropionate, p-xylene and o-dichlorobenzene into the reaction vessel, mix and heat up to 100°C to obtain a mixture Liquid I;

[0042] (2) Weighing p-chloromethylstyrene, butyl methacrylate, benzoyl peroxide and 1 / 3 of the formula amount of azoisobutylcyanoformamide and 2 / 3 of the formula amount of azo Diisobutyronitrile, after mixing, use a constant pressure dropping funnel to drop into the mixed solution I at a constant speed for 3 hours, raise the temperature to 120°C, and keep it warm for 1 hour to obtain the mixed solution II;

[0043] (3) Cool the mixed solution II to 45°C, then add 2 / 3 of the recipe amount of azoisobutylcyanoformamide and th...

Embodiment 2

[0047] p-Chloromethylstyrene / butyl methacrylate, isobornyl methacrylate grafted with methyl nicotinate pyridinium salt

[0048] The reaction material charging capacity is shown in Table 1, and the preparation method comprises the following three steps:

[0049] (1) Add 1 / 3 of the recipe amount of azobisisobutyronitrile, and the recipe amount of isooctyl mercaptopropionate, p-xylene and o-dichlorobenzene into the reaction vessel, mix and heat up to 110°C to obtain a mixture Liquid I;

[0050] (2) take by weighing the azoisobutylcyanoformamide of formula quantity, butyl methacrylate, isobornyl methacrylate, benzoyl peroxide and 1 / 3 formula quantity and 2 Azobisisobutyronitrile in a formula amount of / 3, after mixing, use a constant pressure dropping funnel to drop it into the mixed solution I at a constant speed for 4 hours, raise the temperature to 130°C, and keep it warm for 2 hours to obtain the mixed solution II;

[0051] (3) Cool the mixed solution II to 50°C, then add 2 / ...

Embodiment 3

[0055] p-Chloromethylstyrene / Butyl Methacrylate, Isobornyl Methacrylate, 2-Acrylic Acid-2-Methoxyethyl Ester Grafted Methyl Nicotinate Pyridinium Salt

[0056] The reaction material charging capacity is shown in Table 1, and the preparation method comprises the following three steps:

[0057] (1) Add 1 / 3 of the recipe amount of azobisisobutyronitrile, and the recipe amount of isooctyl mercaptopropionate, p-xylene and o-dichlorobenzene into the reaction vessel, mix and heat up to 105°C to obtain a mixture Liquid I;

[0058](2) Weigh p-chloromethylstyrene, butyl methacrylate, isobornyl methacrylate, 2-acrylate-2-methoxyethyl, benzoyl peroxide and 1 / 3 formula The amount of azoisobutyrocyanoformamide and 2 / 3 of the formula amount of azobisisobutyronitrile are mixed and added dropwise to the mixed solution I at a constant speed for 3.5 hours using a constant pressure dropping funnel, and the temperature is raised to 125°C. After 1.5 hours of heat preservation, the mixed solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap