Test device and test method of duration of direction and shift changing clutch of gearbox

A technology of durability test and gearbox, which is applied in the direction of machine gear/transmission mechanism test, etc. It can solve the problem that there is no specific test method and requirement for the reversing gear clutch of the gearbox, so as to improve the efficiency of gear shifting and reduce the test cost , determine reliable and credible effects

Inactive Publication Date: 2018-10-02

XUZHOU XCMG DRIVELINE TECH CO LTD

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, national standards and construction machinery industry standards have durability test methods and requirement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

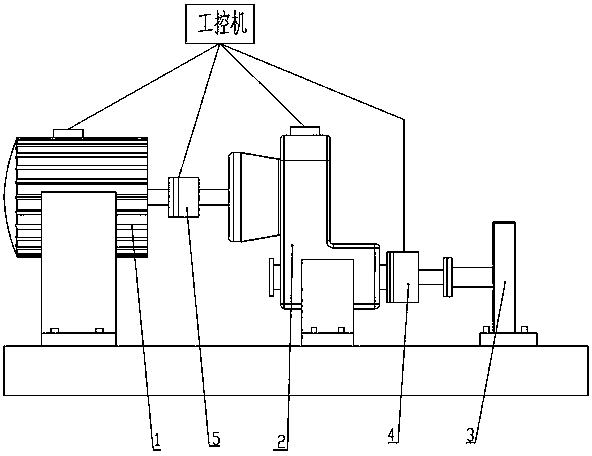

The invention provides a test device and test method of duration of a direction and shift changing clutch of a gearbox. A slotted type test bench device is adopted. The test device comprises an inputmotor, a test gearbox, a rotational inertia disc, an input rotation speed sensor and an output rotation speed sensor. The input motor, the test gearbox and the rotational inertia disc are connected with each other through a transmission shaft. The input rotation speed sensor is arranged on the output end of the input motor. The output rotation speed sensor is arranged on the output end of the testgearbox. The input rotation speed sensor and the output rotation speed sensor acquire speed signals in real time and transmit the speed signals to an industrial personal computer. Through the industrial personal computer, increasing and decreasing of the rotation speed of the input motor are achieved. Based on actual use conditions, reliability of the test is improved and automatic operation is achieved. The device is simple and reliable, there is no need to independently test parts like frictional sheets and clusters and test cost is reduced.

Description

technical field [0001] The invention relates to a reversing gear clutch durability test device and test method applied to a loader gearbox. The method is based on the gearbox assembly, and can realize automatic control and testing of the reversing gear clutch durability test during the prototype test process. Accelerated durability test. Background technique [0002] As the construction machinery of construction machinery, the loader mainly works in mines and construction sites where the environment is relatively harsh. There are many forward and backward reciprocating conditions, and the working hours are long. As the core component of the loader, the gearbox is mainly used to realize the forward and backward shoveling and walking of the vehicle. The forward and reverse clutches control the forward and reverse gears of the gearbox respectively. The shifting process is a process of combining and disengaging the two respectively. Therefore, the life of the reversing gear clu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/02

Inventor 侯广猛龚滏生李翊亢宇琪杨小兵

Owner XUZHOU XCMG DRIVELINE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com