Side-wall forming die and side-wall forming process

A technology of forming mold and forming process, applied in the field of car body, can solve problems such as aluminum plate cracking, and achieve the effect of avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

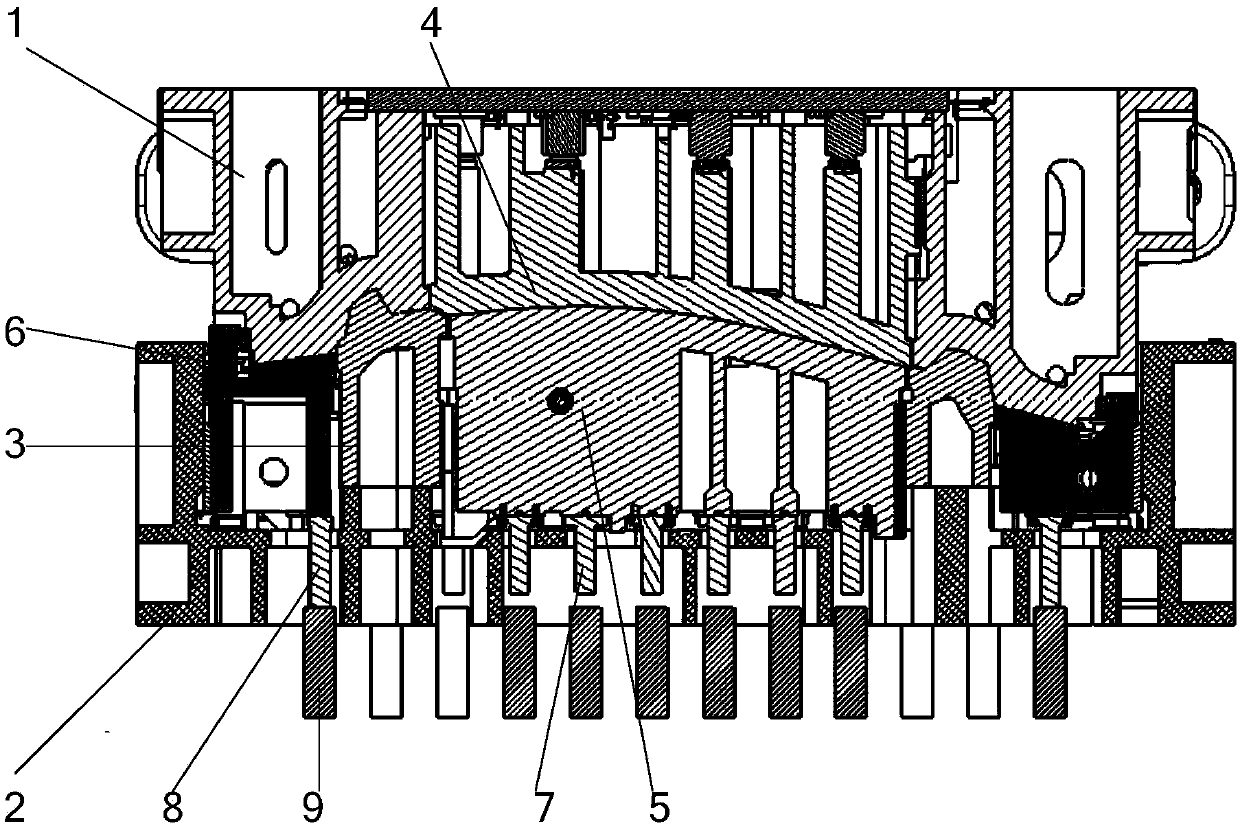

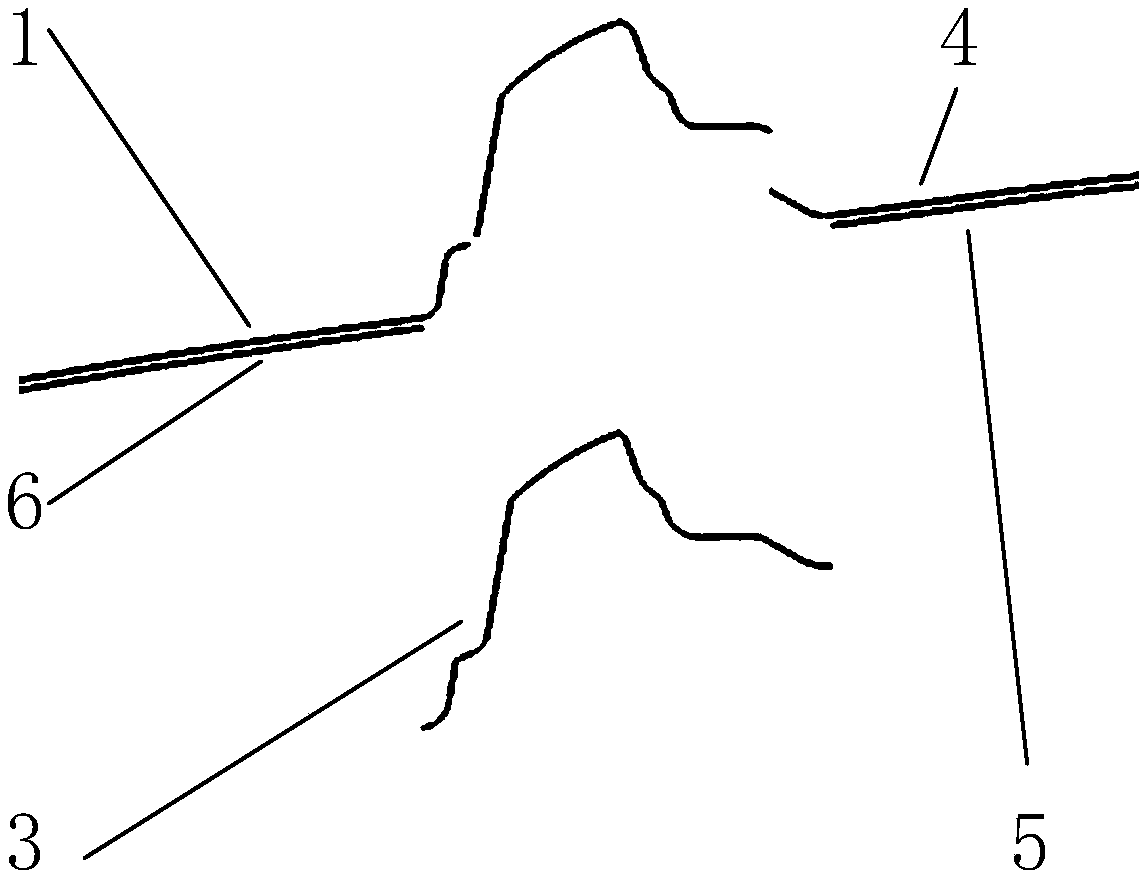

[0048] The embodiment of the present invention provides a side wall forming mold, the side wall forming mold includes an upper mold body 1, a lower mold base 2, a punch 3 arranged on the lower mold base 2, and a compensation device movably arranged on the upper mold body 1 The die 4, the inner binder ring 5 that is movably arranged inside the punch 3 and matches the binder surface of the compensation die 4, the outer binder ring 6 that is movably arranged on the outside of the punch 3; the inner binder The ring 5 is equipped with an inner second-stage ejector pin 7, and the outer blank holder ring 6 is equipped with an outer second-stage ejector pin 8; wherein: the length of the inner second-stage ejector pin 7 is shorter than the length of the outer second-stage ejector pin 8, and in the mold In the closed state, the lower end surface of the inner secondary ejector rod 7 is higher than the lower end surface of the outer secondary ejector rod 8 by Δh; the upper mold body 1 is a...

Embodiment 2

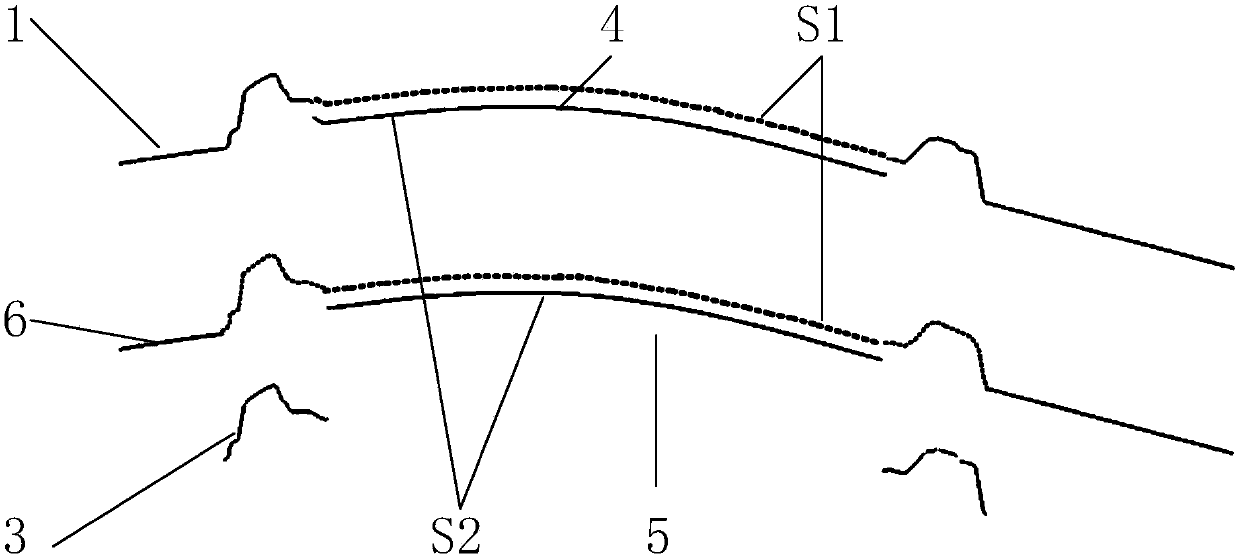

[0055] This embodiment provides a side wall forming process, wherein: the above side wall forming die is used for side wall drawing and forming. In this embodiment, the inner binder ring 5 is only rigidly limited by the lower mold base 2, so that The inner blank holder 5 has only one limit position, and during specific implementation, the side enclosure forming process is as follows: Figure 8 shown, including the following steps:

[0056] Step S10: First, the upper mold body 1 and the punch 3 are in the mold-opening state; then, the ejector rod 10 of the machine tool moves upward, and the ejector rod 10 of the machine tool first contacts the outer secondary ejector rod 8 and lifts up 6, and then the ejector rod 10 of the machine tool moves up again. Contact the inner secondary push rod 7 and jack up the inner binder ring 5, so that the inner binder ring 5 and the outer binder ring 6 move to the same height. At this time, the inner binder ring 5 and the upper surface of the ou...

Embodiment 3

[0067] This embodiment provides a side wall forming process, wherein: the above side wall forming die is used for side wall drawing and forming. The difference between this embodiment and Embodiment 2 is that in this embodiment, the inner binder ring 5 At the same time, the lower die nitrogen spring and the lower die seat 2 are used to limit the position respectively. At this time, it is required to set the lower die nitrogen spring on the lower die to provide the driving force and pressure source; set the stroke and force of the lower die nitrogen spring, and the lower die nitrogen spring The active force of the inner binder ring 5 can be used as the pressure source of the inner binder ring 5, and the inner binder ring 5 is limited during the mold clamping process, and the stroke of the lower mold nitrogen gas spring can be used as the elastic stroke of the inner binder ring 5, and the lower mold seat 2 pairs of inner blank holders 5 provide rigid spacing. During the mold clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com