Backlight module and display device

A backlight module and display device technology, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as hole digging light leakage, insufficient bonding of light-shielding tape, light leakage at the edge of the effective display area, etc., and achieve the effect of reducing the border width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

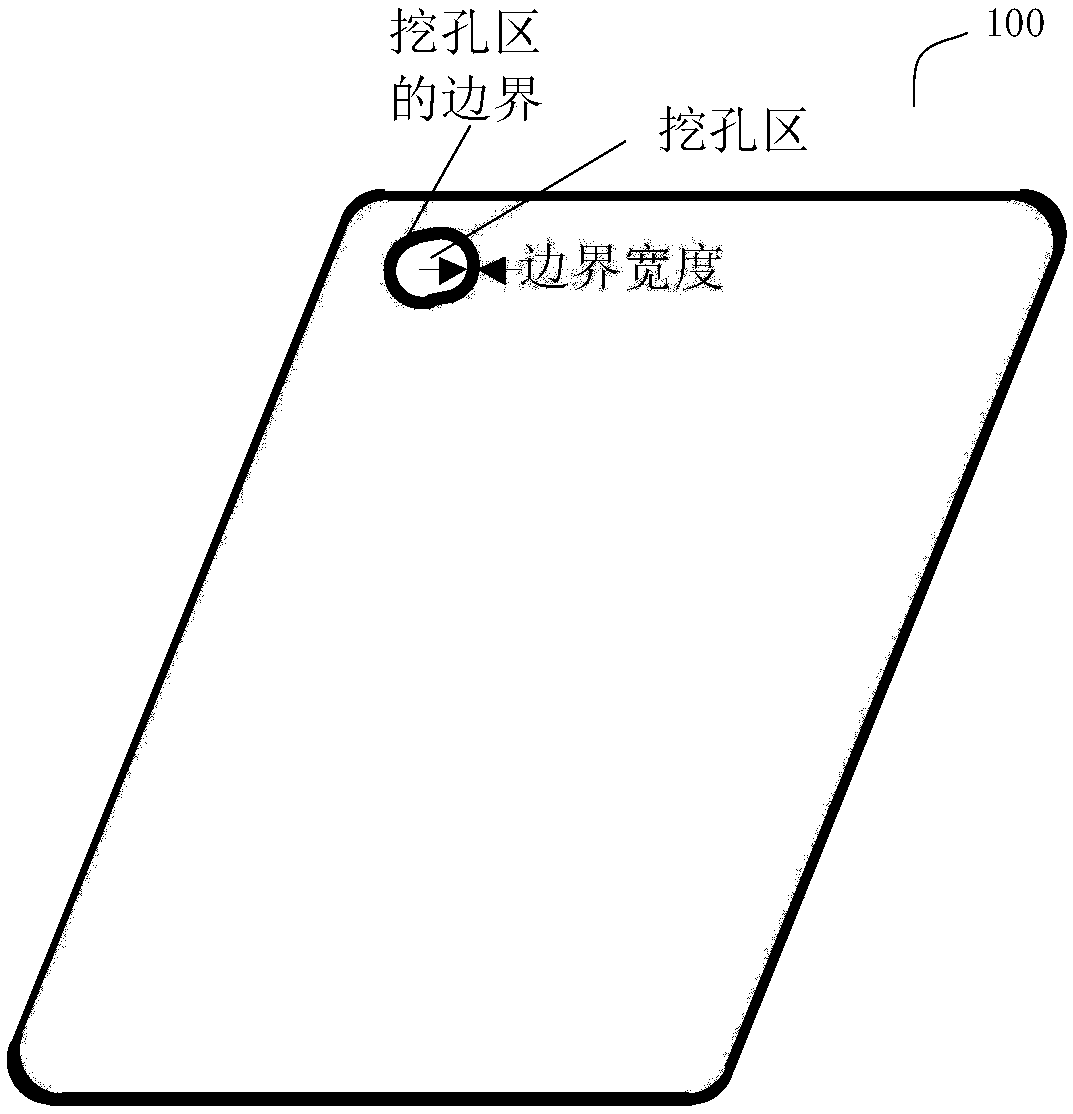

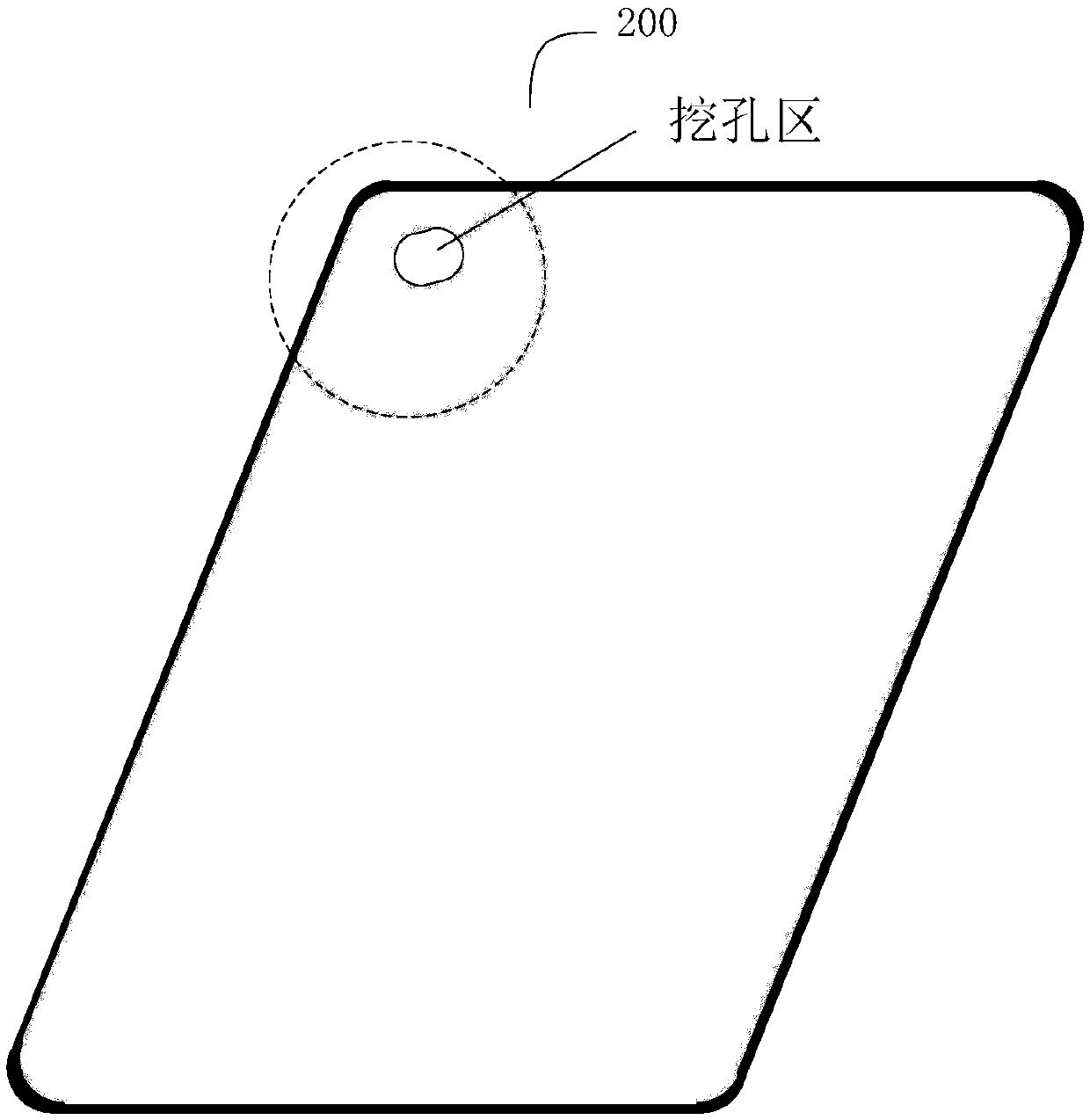

[0044] The embodiments of the present invention provide a backlight module and a display device to solve the technical problem in the prior art that the boundary width of the hole-digging area is relatively wide.

[0045] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

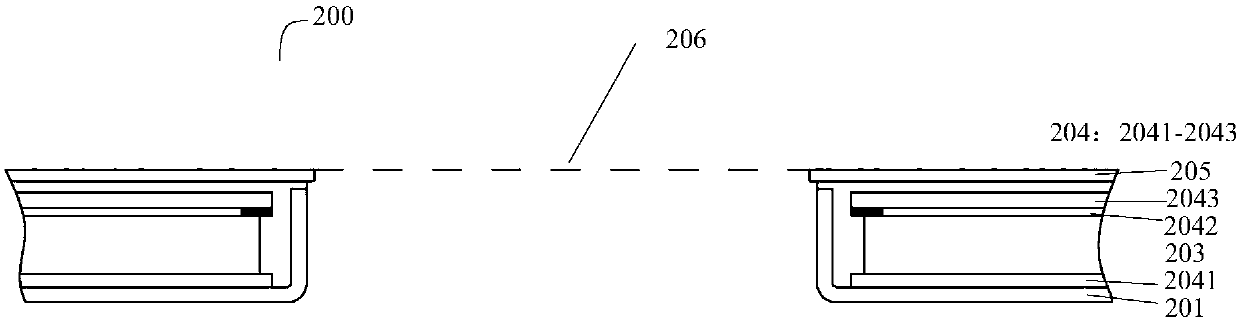

[0046] A backlight module is provided, including: an iron frame, a backlight source, a light guide plate and a film material, wherein the iron frame is used to support the backlight source, the light guide plate and the film material. Specifically, the backlight module has a through hole; wherein, the through hole runs through the light guide plate and the film material; the iron frame includes an iron frame body and a cylindrical structure located at the position of the through hole, and the iron frame body extends along the inner wall of the through hole to form a cylindrical shape structure.

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com