Backlight module and liquid crystal display device

A technology of backlight module and optical module, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of not being able to meet customer needs and the frame width of liquid crystal displays, so as to improve user experience, reduce frame width, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

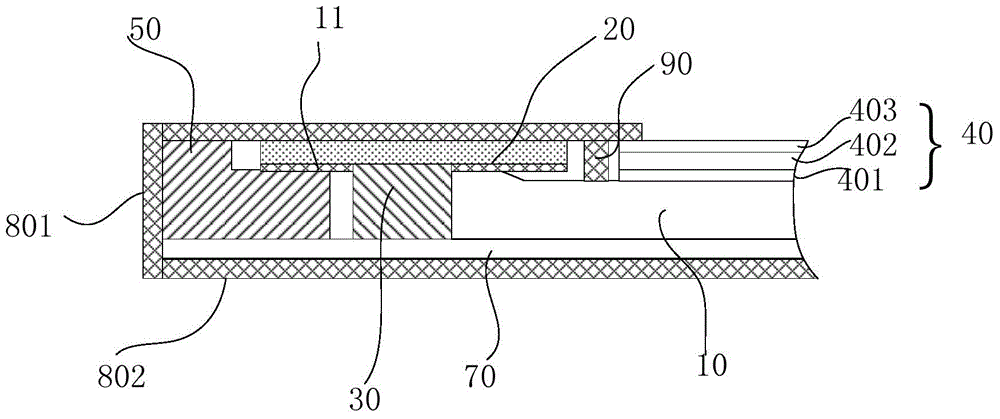

[0089] This embodiment provides a liquid crystal display device, such as Figure 4 shown, including:

[0090] The liquid crystal display panel 100 includes: an array substrate, a color filter substrate, and a liquid crystal layer between the array substrate and the color filter substrate;

[0091] The array substrate includes: multiple data lines, multiple scan lines and multiple pixel units;

[0092] The data line is used to transmit data signals;

[0093] The scanning lines are used to transmit scanning signals;

[0094] The pixel unit is used to display a picture according to the data signal and the scanning signal;

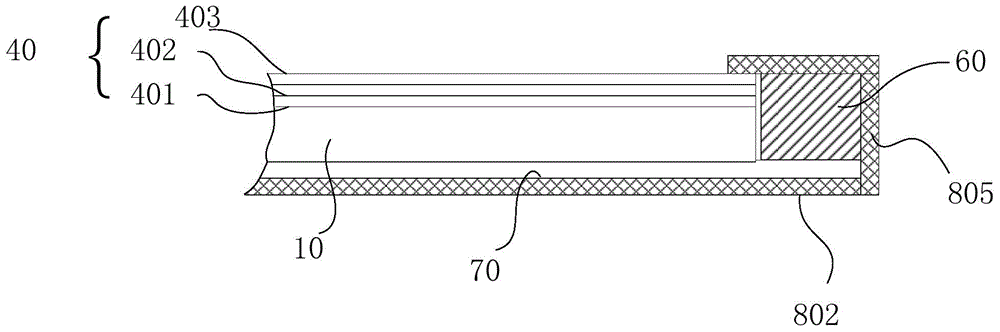

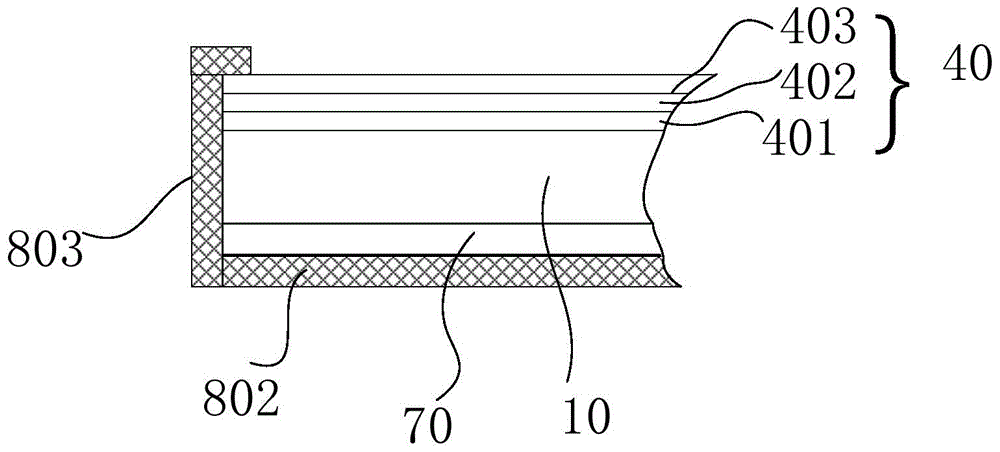

[0095] The backlight module located under the liquid crystal display panel is used to provide a light source for the liquid crystal panel, including:

[0096] reflective sheet 70 for reflecting light;

[0097] The light guide plate 10 is arranged on the reflective sheet 70 to form a surface light source; the light guide plate 10 has a light incident surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com