Performance testing method for pressure sensor

A pressure sensor and testing method technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of inaccurate and bad pressure testing, and achieve the effects of not affecting production efficiency, simple process logic, and fast testing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

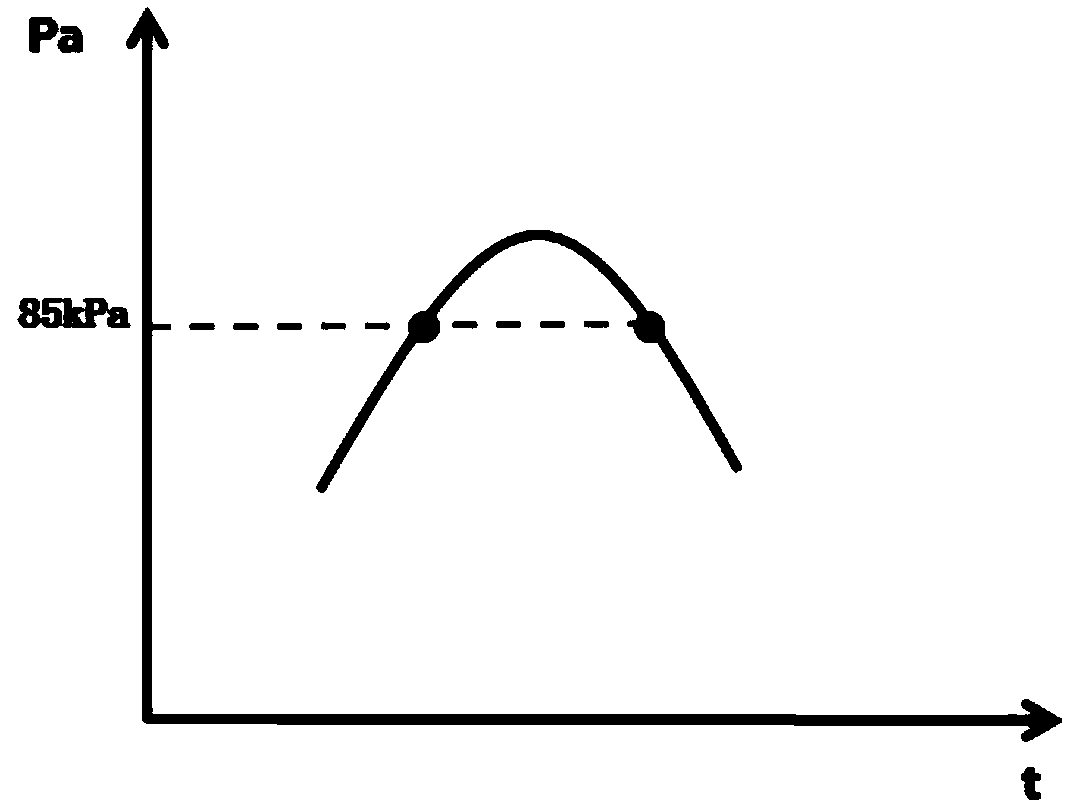

[0057] The second embodiment: After the pressure sensor is depressurized first, then the pressure is increased to the 85kPa pressure point for testing, so as to compare whether the pressure values of the two tests are the same, as long as the error of the tested pressure values is within ± 40Pa, then It is judged that the absolute pressure accuracy of the pressure sensor is qualified after the buck-boost test.

[0058] In the above two test processes, no matter which test method is selected, the buck-boost test can be performed. According to the convenience in practical application, any one of the above two embodiments can be selected arbitrarily.

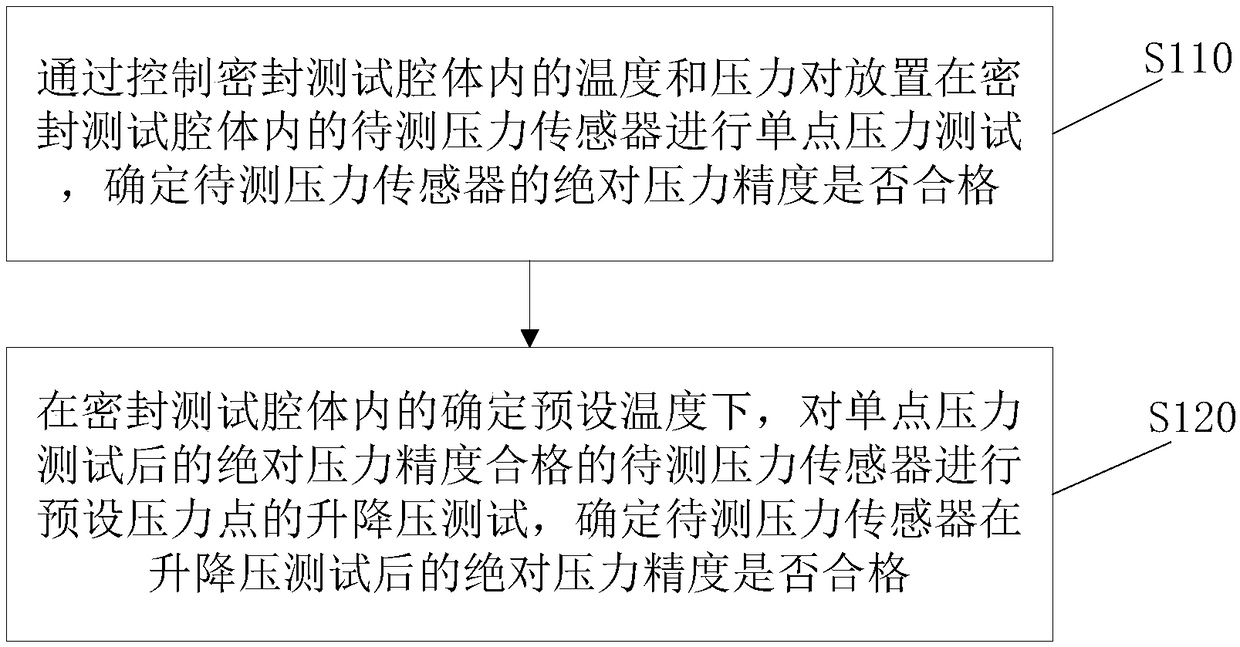

[0059] It can be seen from the above embodiments that the performance testing method of the pressure sensor provided by the present invention tests the pressure sensor to be tested by combining the single-point test and the buck-boost test, so as to test out unqualified products. The performance test method of this pressure sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com