Reed end shaping system and shaping method

A technology of end shaping and reed, which is applied in the field of leaf spring processing devices, can solve the problems of reed raw materials, waste cannot be recycled, and tool wear is fast, so as to save the cost of tools, reduce equipment wear, and save tool replacement. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

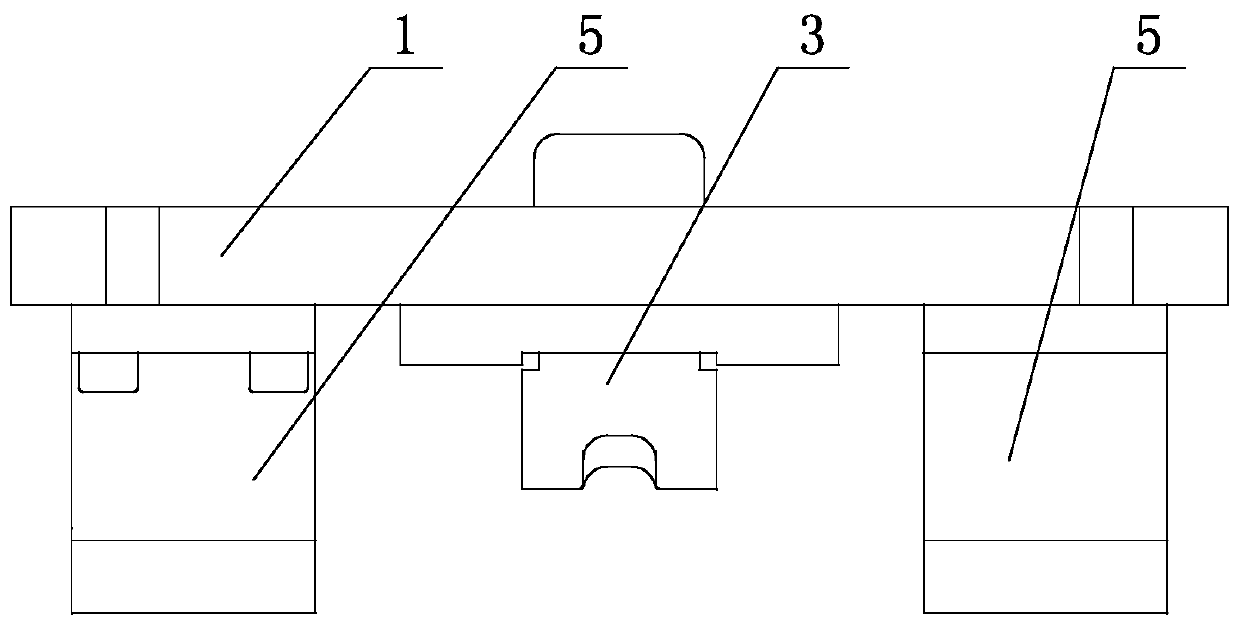

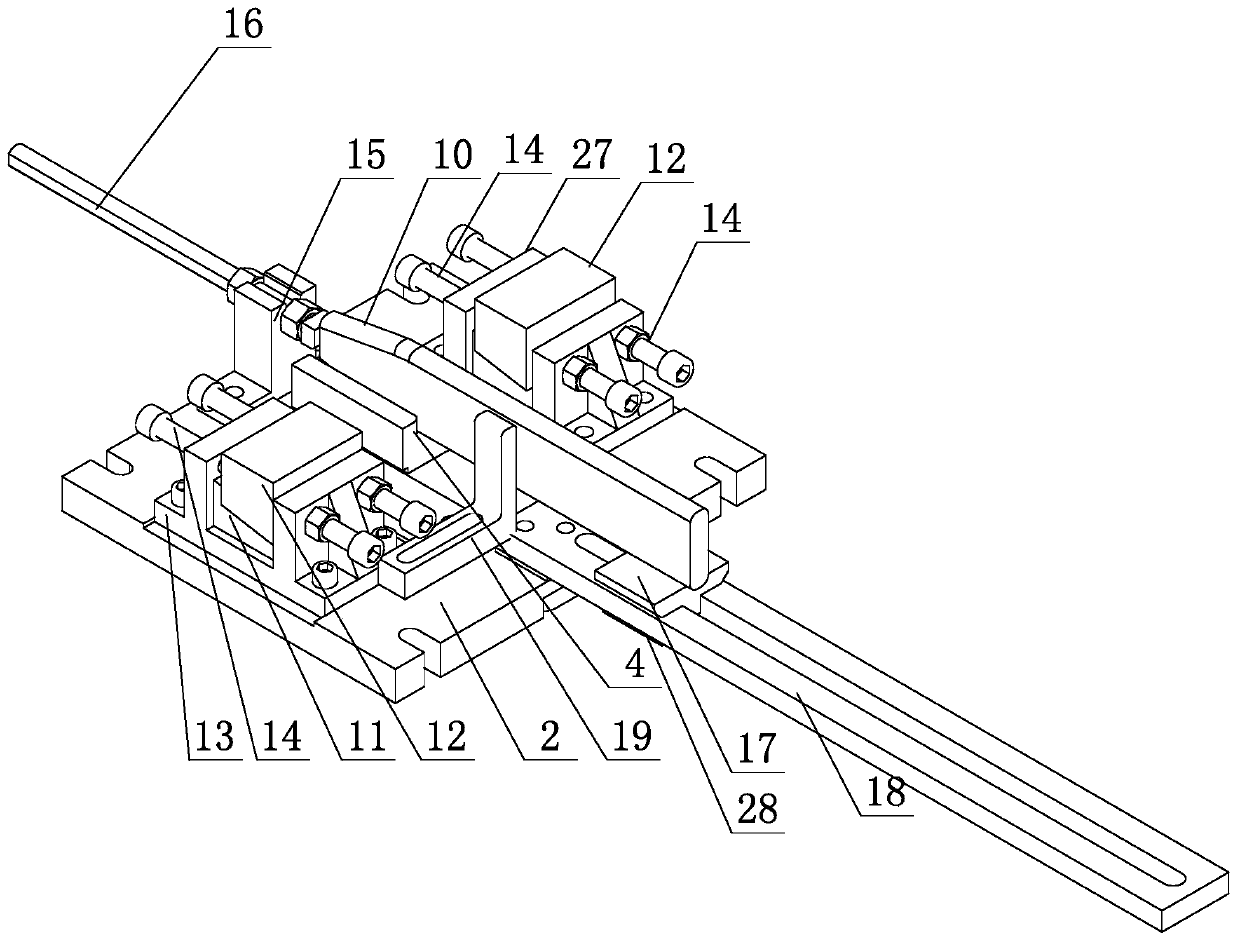

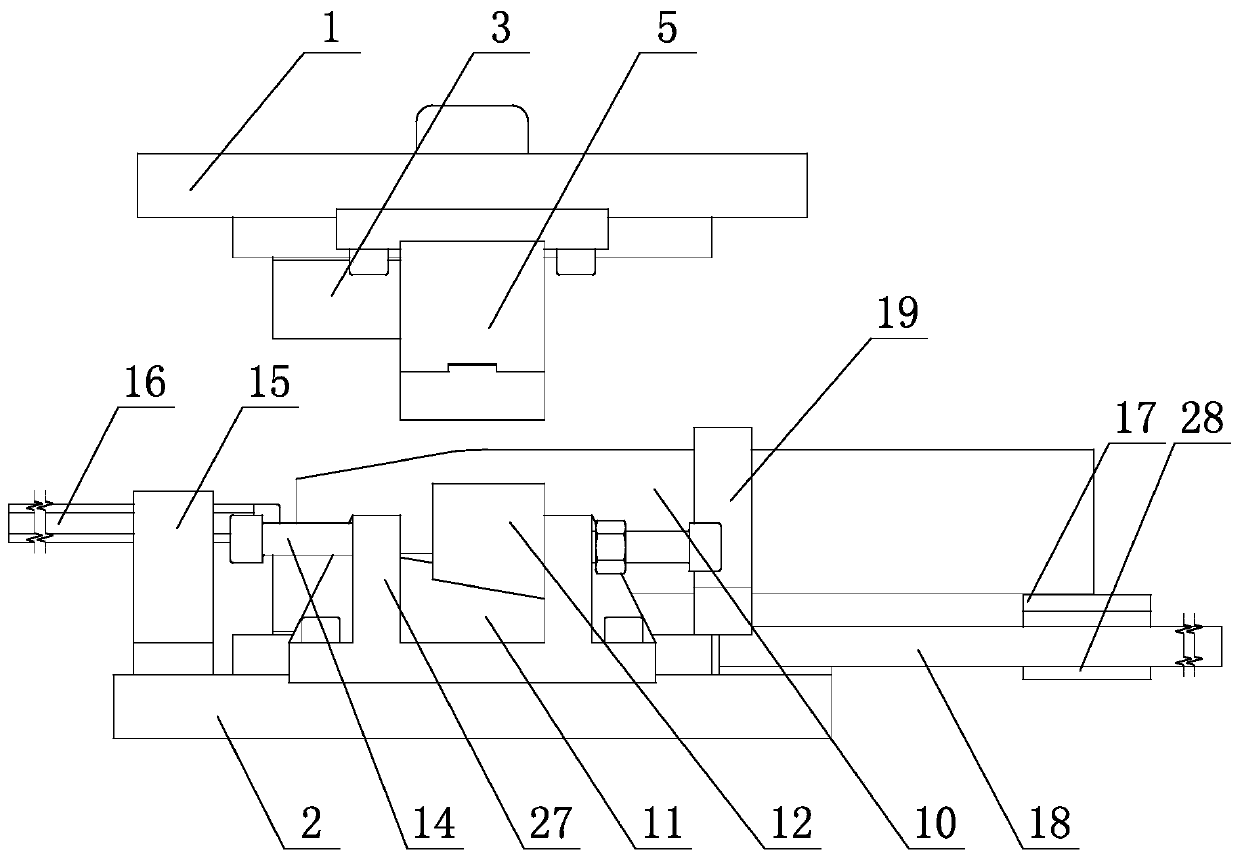

[0044] The reed end shaping system includes a reed extruding die and a reed racket die, wherein:

[0045] like Figure 1-3 As shown, the reed extrusion head mold includes an upper extrusion head template 1 and an extrusion head lower template 2, and an upper extrusion head seat 3 and a lower extrusion head seat 4 are relatively arranged on the extrusion head upper template 1 and the extrusion head lower template 2. The extrusion head briquetting blocks 5 are fixed on both sides of the extrusion head seat 3, the extrusion head height adjustment parts are set on both sides of the lower extrusion head seat 4 corresponding to the extrusion head block 5, and the extrusion head is set on the front end of the lower extrusion head seat 4 corresponding to the extrusion head lower template 2 As for the positioning part, the extrusion head supporting piece is arranged on the rear end of the extrusion head lower template 2 corresponding to the lower extrusion head seat 4;

[0046] like ...

Embodiment 2

[0053] This embodiment provides a method for reed end shaping on the basis of Embodiment 1, comprising the following steps:

[0054] The first step is to cut off the material, and cut the spring flat steel into reed 10 according to the required length;

[0055] The second step, drilling, drills the center hole for the reed 10 by the drilling mold;

[0056] The third step is heating, the reed 10 is heated at the end by intermediate frequency, and the heating length is determined according to the end processing length of the reed 10;

[0057] The fourth step is to squeeze the head, and squeeze the reed 10 through the reed head extrusion die;

[0058] The fifth step is the racket head, and the reed 10 is racketed through the reed racket head mold.

[0059] The first step to the third step above are the same as the existing process, and the specific process will not be repeated. The specific process of the fourth step is:

[0060] Place the heated reed 10 on the lower extrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com