Storage box suitable for automobile parts

A technology of auto parts and storage boxes, which is applied in the field of auto parts, can solve the problems that affect the efficiency of manufacturing and maintenance, the storage of parts is disorderly, and the parts cannot be classified, so as to achieve the effects of stable support, convenient access and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

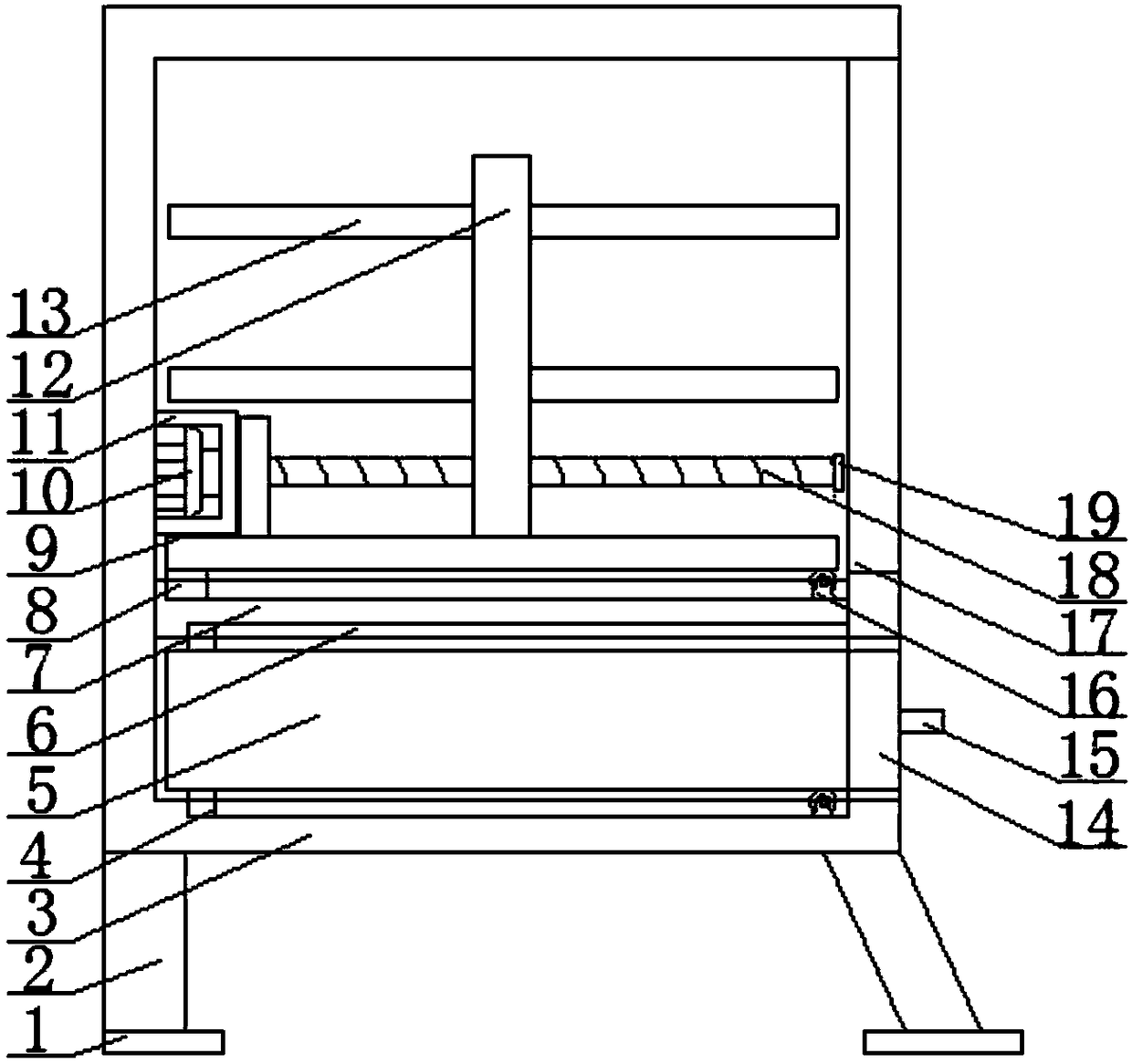

[0024] refer to figure 1 , a storage box suitable for auto parts, including a box body 3, the four corners of the lower end of the box body 3 are all inclined to be provided with support blocks 2, the lower ends of the four support blocks 2 are fixed with a backing plate 1, and the box body 3 is equipped with There is a cavity, and a horizontal plate 7 is fixed between the opposite side walls in the cavity. The horizontal plate 7 divides the cavity from top to bottom into a placement area and an installation area. Both sides of the upper end of the horizontal plate 7 are provided with a second Two T-shaped chutes, the second T-shaped slide block 8 is installed in the second T-shaped chute, the other side in the second T-shaped chute is fixed with a roller 16, two second T-shaped slide blocks 8 The upper end is jointly fixed with a moving plate 9, and the lower end side of the moving plate 9 is in contact with the upper ends of the two rollers 16, which facilitates the picking ...

Embodiment 2

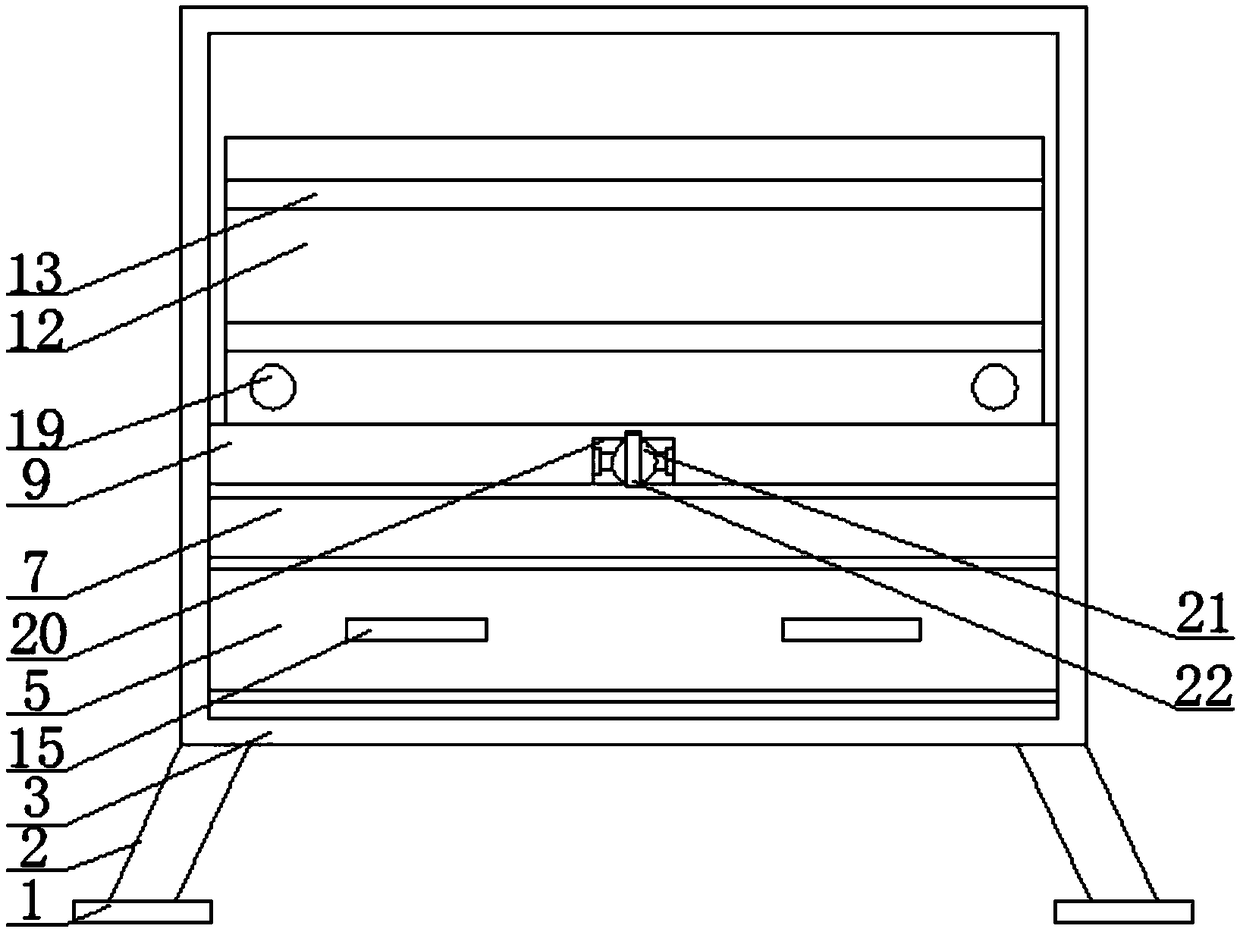

[0027] refer to figure 1 , 2 , a storage box suitable for auto parts, including a box body 3, the four corners of the lower end of the box body 3 are all inclined to be provided with support blocks 2, the lower ends of the four support blocks 2 are fixed with a backing plate 1, and the box body 3 is equipped with There is a cavity, and a horizontal plate 7 is fixed between the opposite side walls in the cavity. The horizontal plate 7 divides the cavity from top to bottom into a placement area and an installation area. Both sides of the upper end of the horizontal plate 7 are provided with a second Two T-shaped chutes, the second T-shaped slide block 8 is installed in the second T-shaped chute, the other side in the second T-shaped chute is fixed with a roller 16, two second T-shaped slide blocks 8 The upper end is jointly fixed with a moving plate 9, and the lower end side of the moving plate 9 is in contact with the upper ends of the two rollers 16, which facilitates the pic...

Embodiment 3

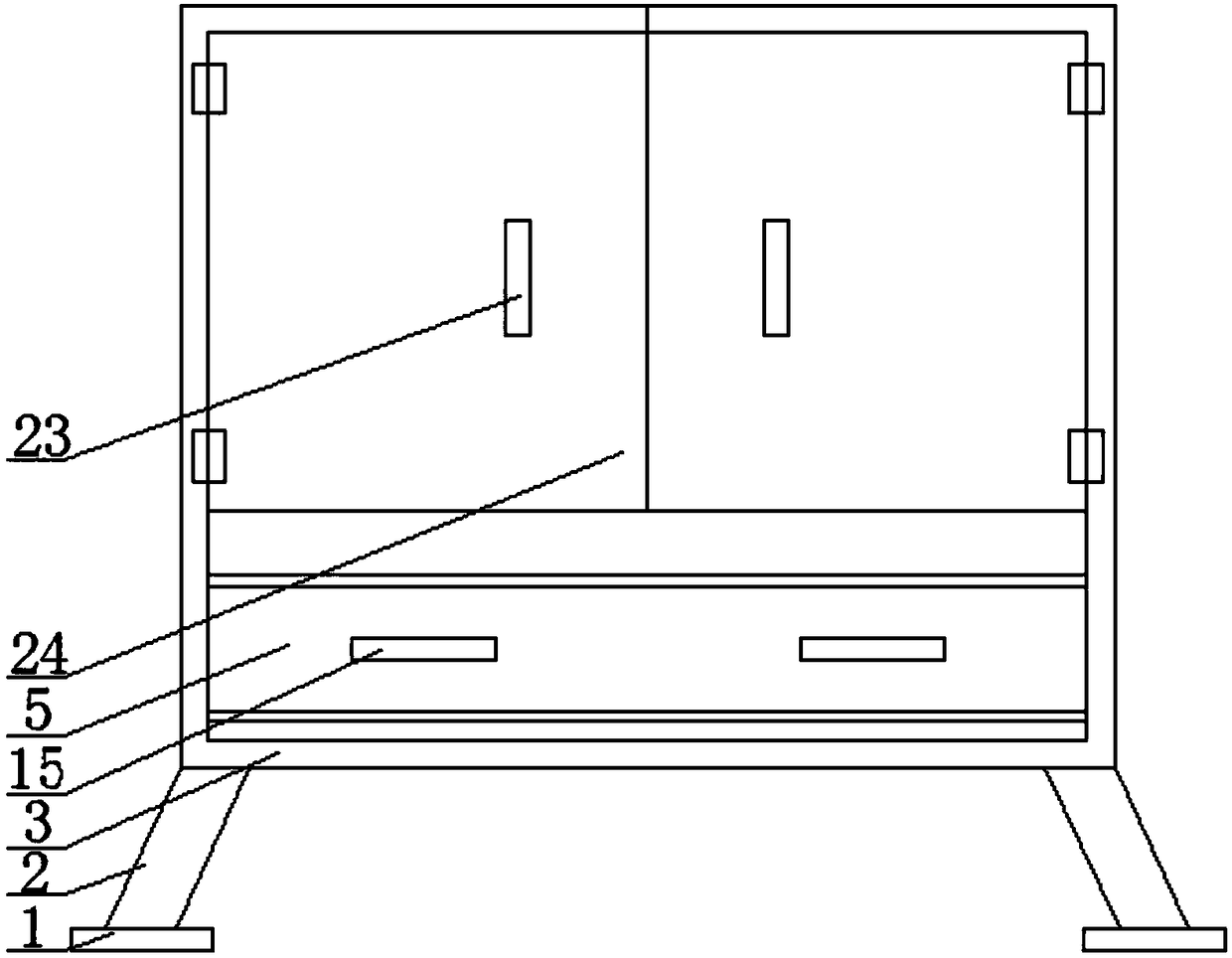

[0031] refer to figure 1 , 3, 4, a storage box suitable for auto parts, including a box body 3, the four corners of the lower end of the box body 3 are all inclined to be provided with support blocks 2, the lower ends of the four support blocks 2 are fixed with a backing plate 1, the box body 3 There is a cavity inside, and a horizontal plate 7 is fixed between the opposite side walls in the cavity. The horizontal plate 7 separates the cavity from top to bottom into a placement area and an installation area. Both sides of the upper end of the horizontal plate 7 are provided with There is a second T-shaped chute, a second T-shaped slider 8 is installed in the second T-shaped chute, a roller 16 is fixed on the other side of the second T-shaped chute, and two second T-shaped sliders The upper end of 8 is jointly fixed with moving plate 9, and one side of the lower end of moving plate 9 collides with the upper ends of two rollers 16, which facilitates the picking and placing of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com