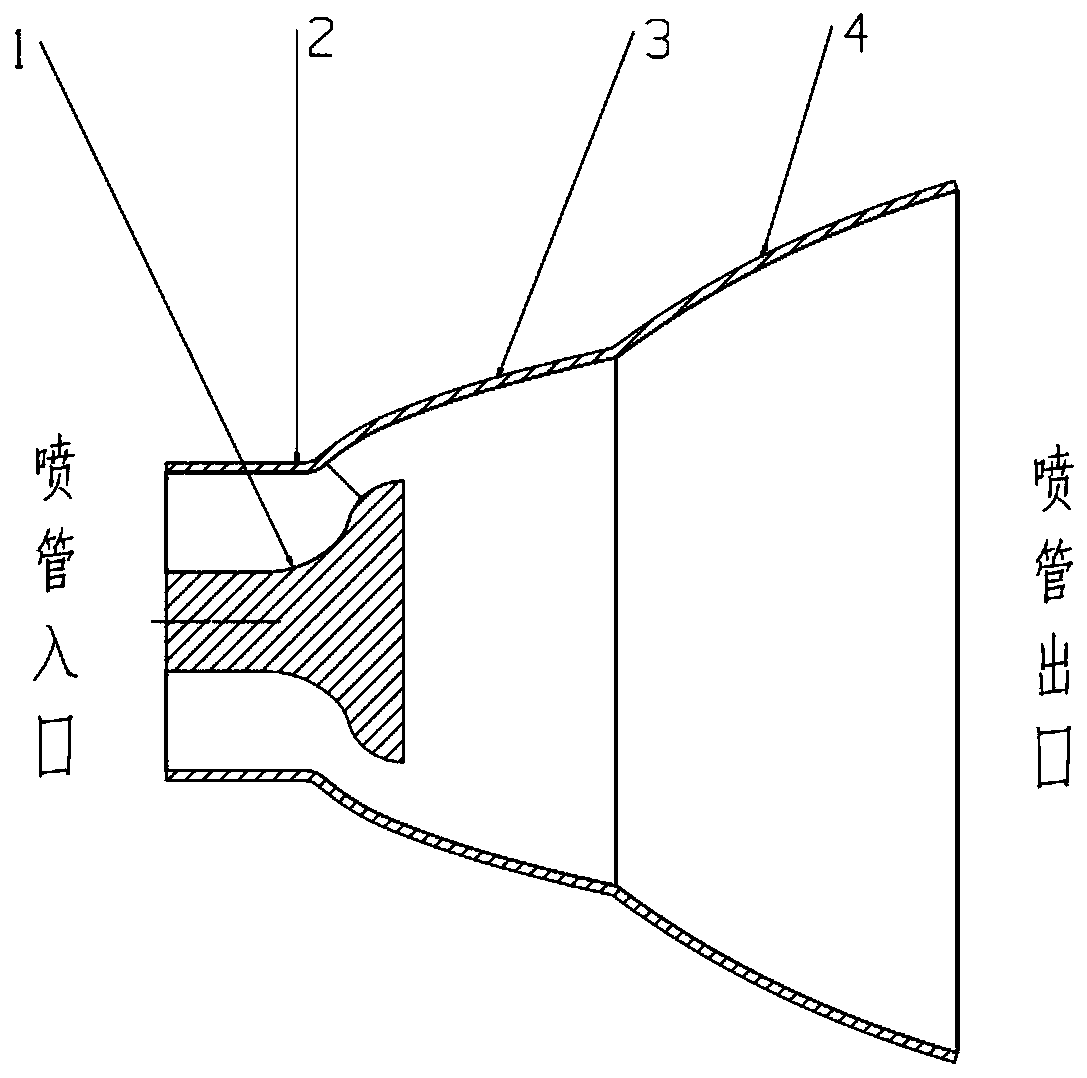

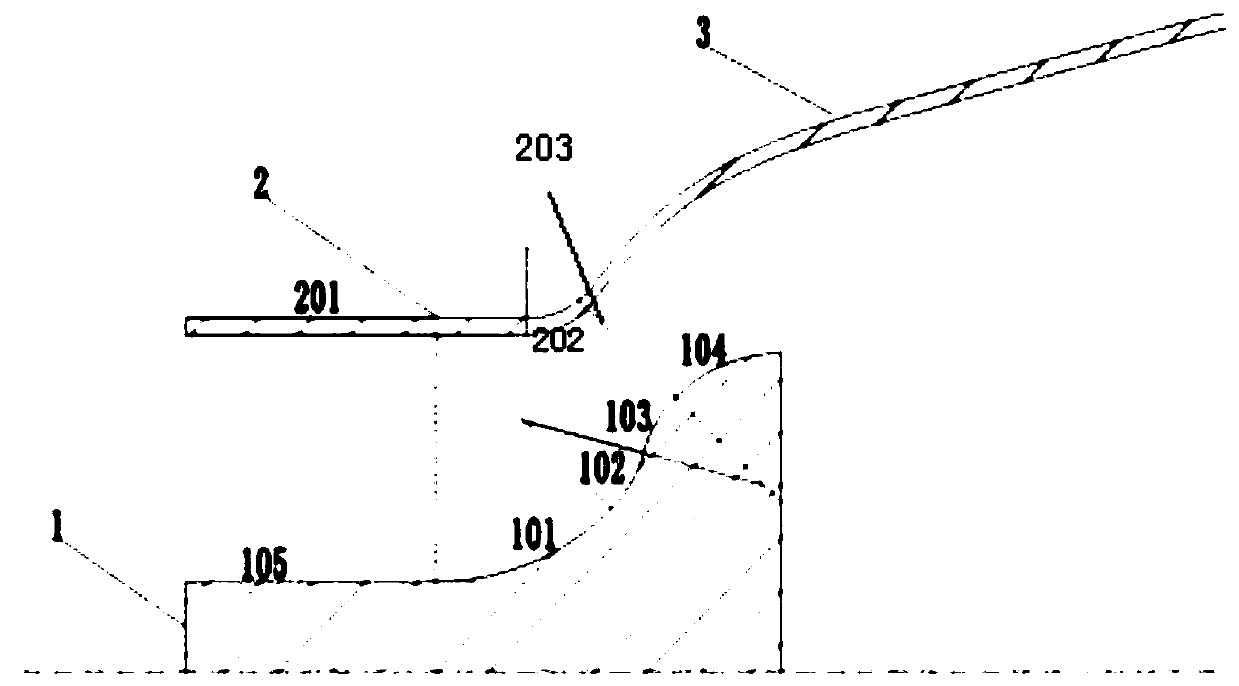

A Double-Bell Expansion-Deflection Nozzle

A bell and nozzle technology, applied in the aerospace field, can solve the problems of deterioration of thrust performance, controversial compensation effect, large cooling area, etc., and achieve the effects of high thrust performance, universal design method, and effective operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

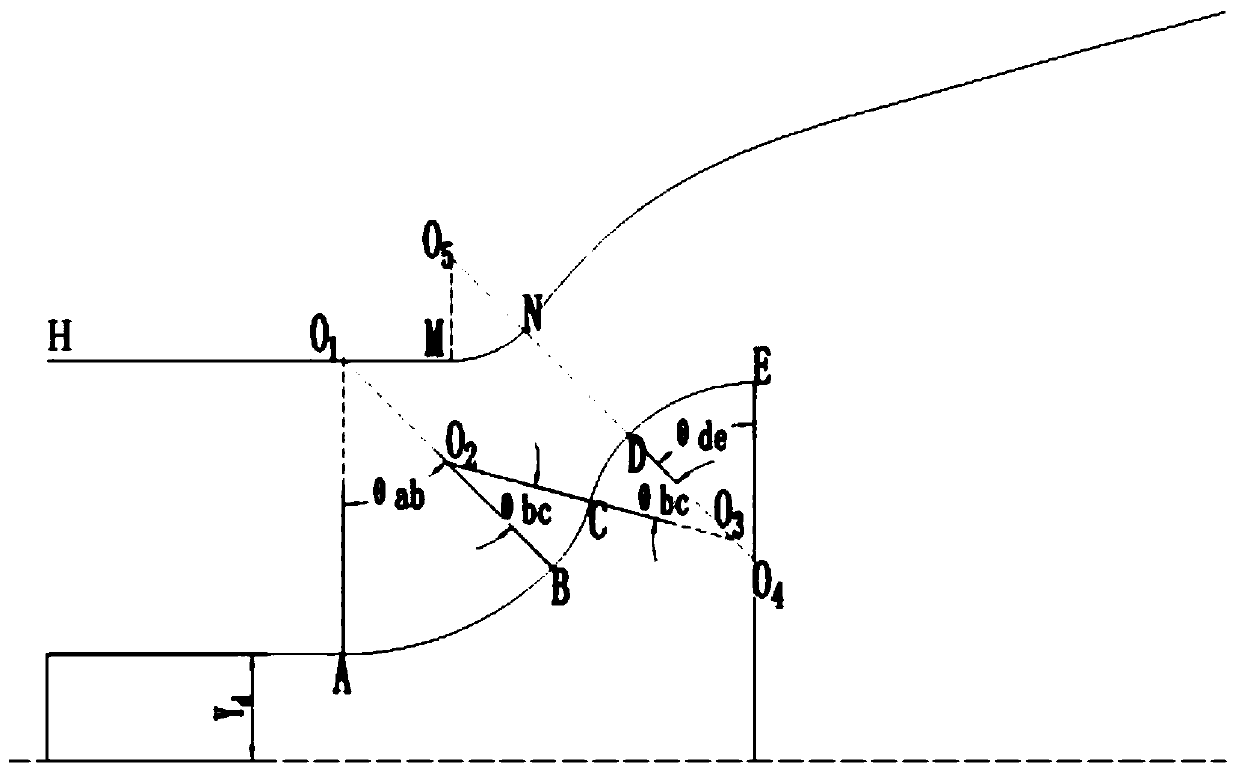

[0049] Example 1: A certain double bell-expansion deflection nozzle needs to work within a wide range of drop pressure ratio, and the throat area A of the nozzle is selected according to the engine operating parameters and flow requirements t ; In order to alleviate the problem of gas over-expansion at low pressure ratios and ensure that the advantages of the expansion and deflection part of the nozzle are effectively utilized, the design pressure ratio of the expansion section of the double bell-shaped foundation is selected to be 50. The design pressure ratio of the double-bell-shaped extension and expansion section is set at 250, and the expansion area ratio of the nozzle can be calculated according to this parameter.

[0050] The specific parameters of the designed expansion deflection plug cone 1 are as follows, combined with image 3 , Radius R of plug cone entrance arc AB Take 2Gt, the central angle θ ab is 30 degrees, the plug cone deflects the arc R BC Take 1Gt, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com