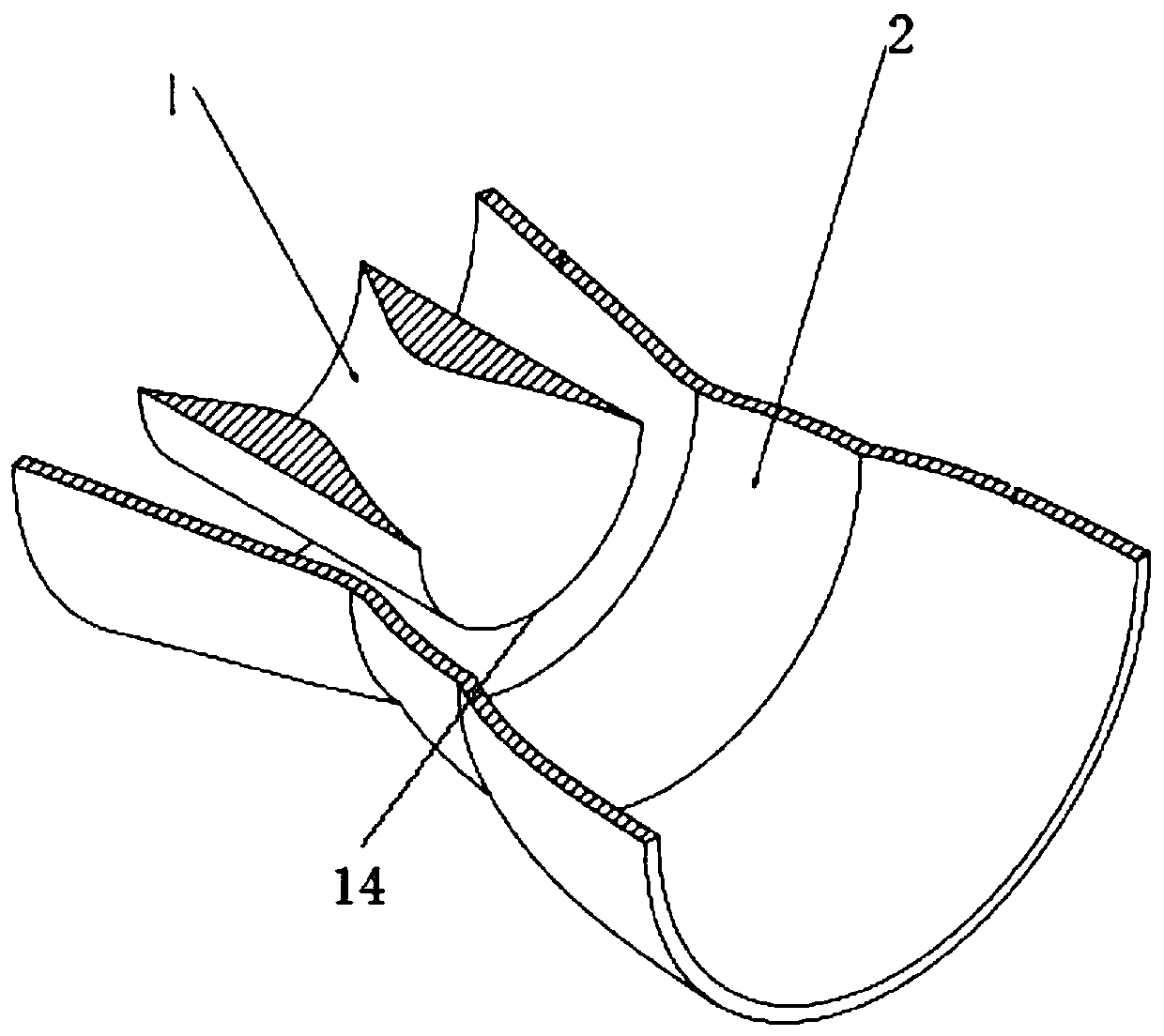

An ejector nozzle with double bell-shaped ejector sleeves

A technology for ejecting nozzles and casings, applied in the aerospace field, can solve problems such as high thrust performance, achieve high thrust performance, avoid excessive expansion, and avoid gas underexpansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

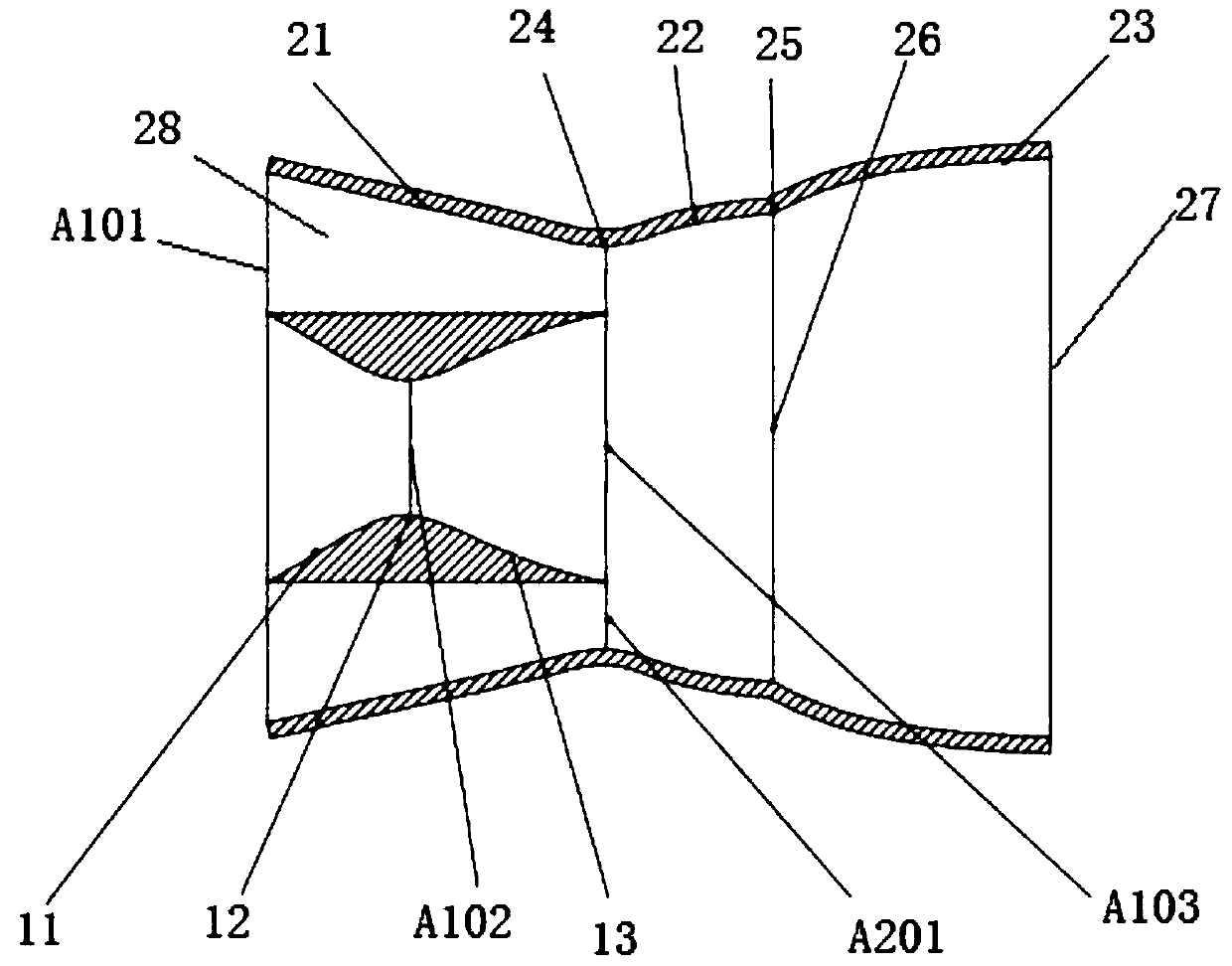

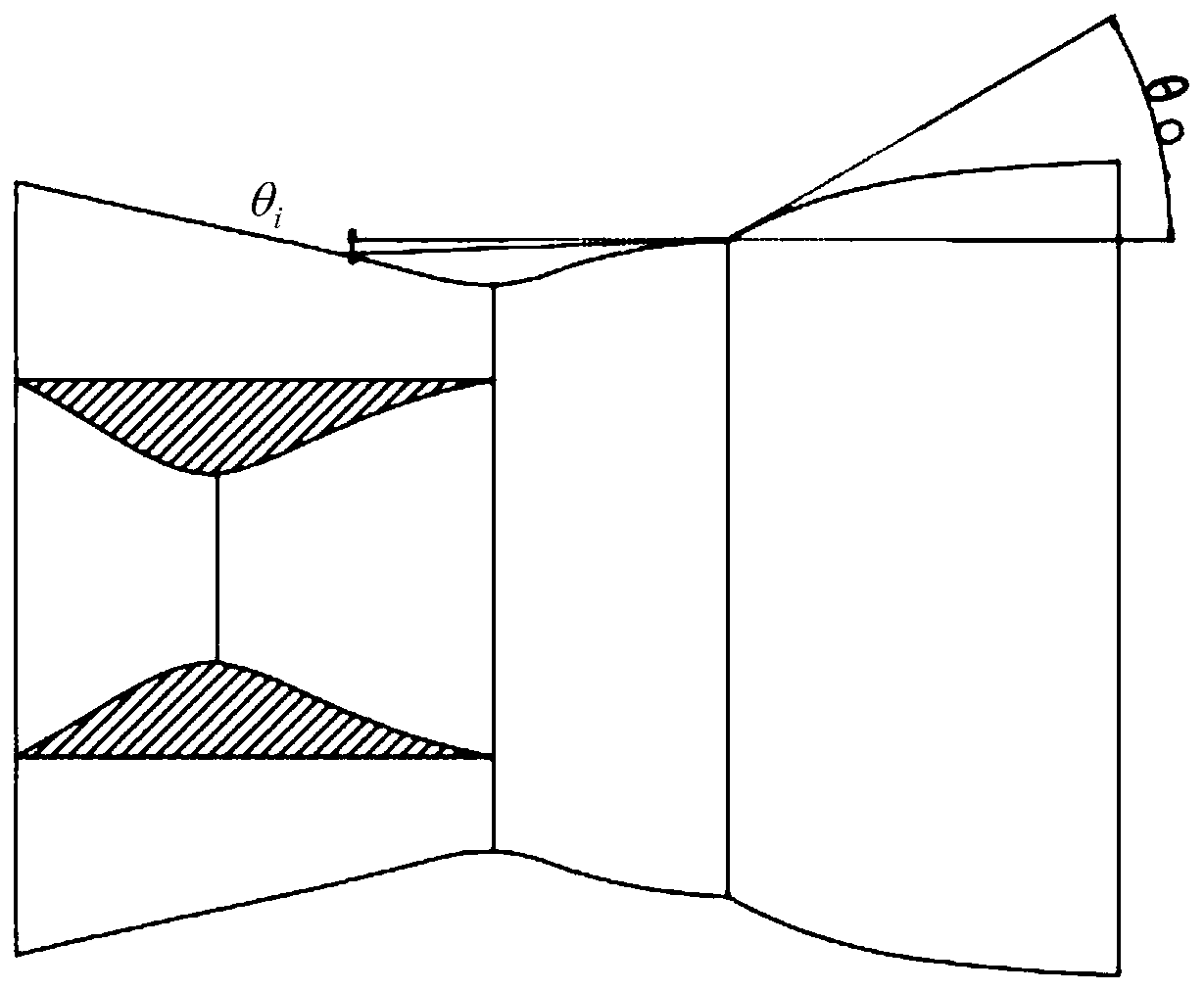

[0041] Embodiment 1, combining Figure 4 , an ejector nozzle with double bell-shaped ejector sleeves with a working Mach number range of 0-6 Ma, the working pressure ratio is above 500, the throat area of the main nozzle is selected according to the engine design parameters, and the engine inlet Working characteristics Select the throat area of the ejector casing.

[0042] The ejector nozzle has three main state points that need to ensure high performance. The first state point is the state point of ground takeoff, and the Mach number is artificially set to Ma=0. The design pressure ratio of the main nozzle is slightly greater than that of the nozzle in the ground takeoff state At this time, the injection channel is in a free suction state, and the jet flow of the main nozzle is completely separated from the double bell-shaped injection sleeve to ensure a reliable thrust coefficient;

[0043] The second state point is the transonic cruising point, and the Mach number is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com