Automatic aligning mechanism for magnetic hysteresis power automatic detection mechanism of air conditioner compressor

An air-conditioning compressor, automatic detection technology, applied in the direction of machines/engines, pump testing, mechanical equipment, etc., can solve the problems that the motor shaft takes a long time, affects work efficiency, and the location is not very accurate, etc., to achieve high efficiency and convenience The effect of unmanned operation, ensuring detection accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

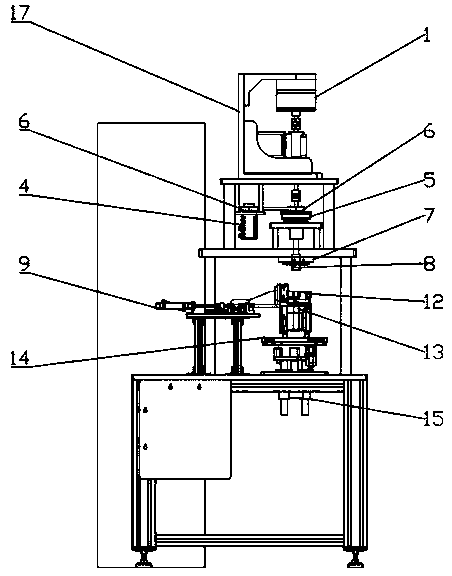

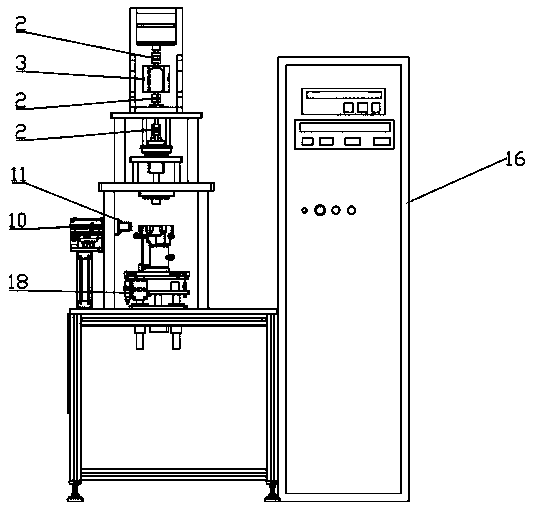

[0010] Combine below figure 1 with figure 2 Specific description embodiment:

[0011] When the tooling plate (14) on which the air conditioner compressor (12) is placed runs to a specific position under the detection fixing seat (17), it is sensed by the proximity switch on the stopper (18), and the plc controls the stopper (18) Block the tooling plate (14). At this time, the jacking cylinder (15) lifts the tooling plate (14) together with the air conditioner compressor (12). The upper cylinder port of the compressor is positioned by the positioning sleeve (7). At this time, the compressor (12 ) inside the eccentric shaft (13) is in contact with the floating sleeve (8) and the eccentric hole is not aligned, and then the stepper motor (4) drives the clutch (5) to rotate through the synchronous pulley (6), so that the clutch (5) connected to the clutch (5) ) on the floating sleeve (8) rotates, so that the floating sleeve (8) aligns with the eccentric pin on the eccentric shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com