Special constant temperature shower for gas water heater

A technology for gas water heaters and showers, which can be used in showers, appliances, bathtubs, etc., and can solve problems such as failure to ignite and gas flameout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

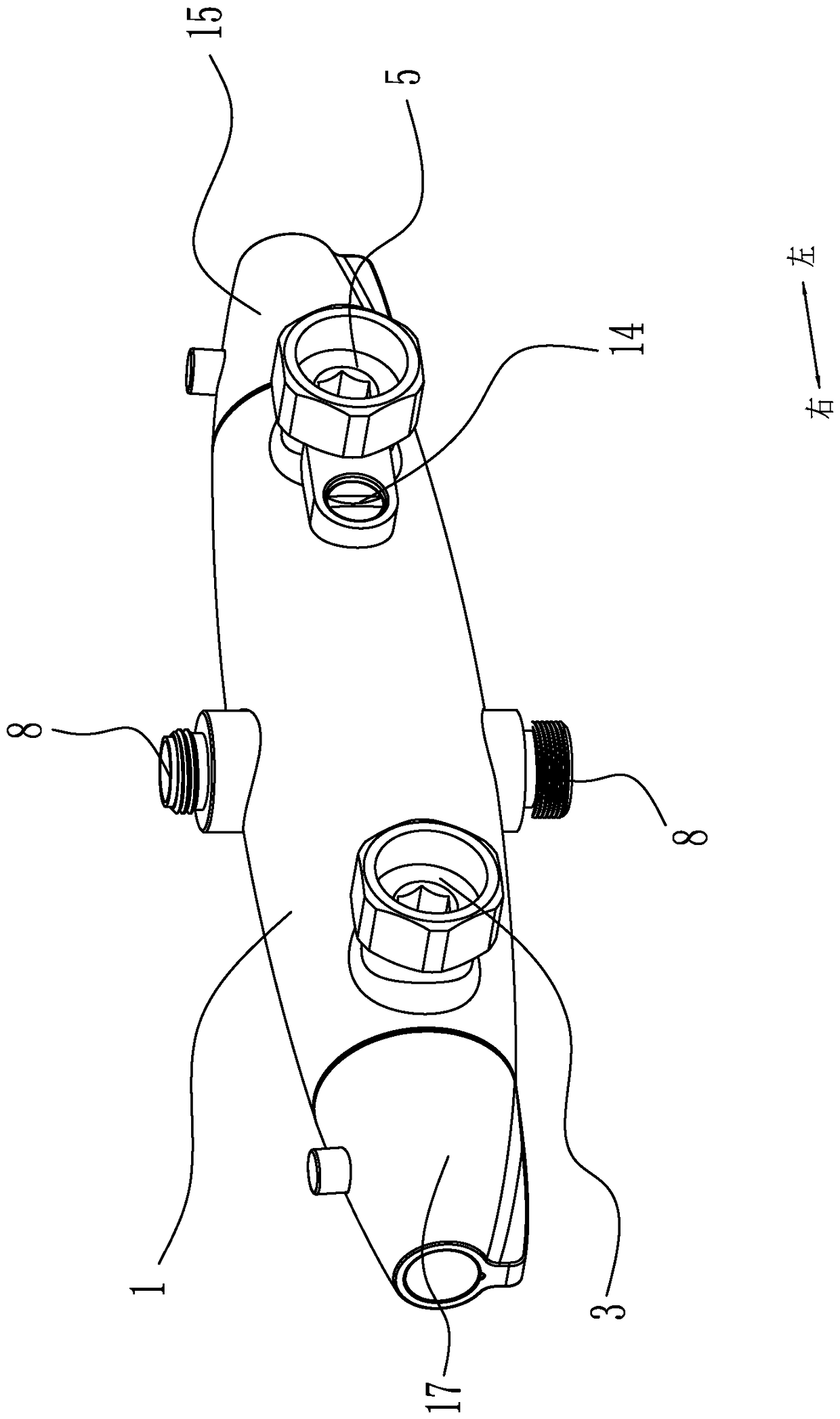

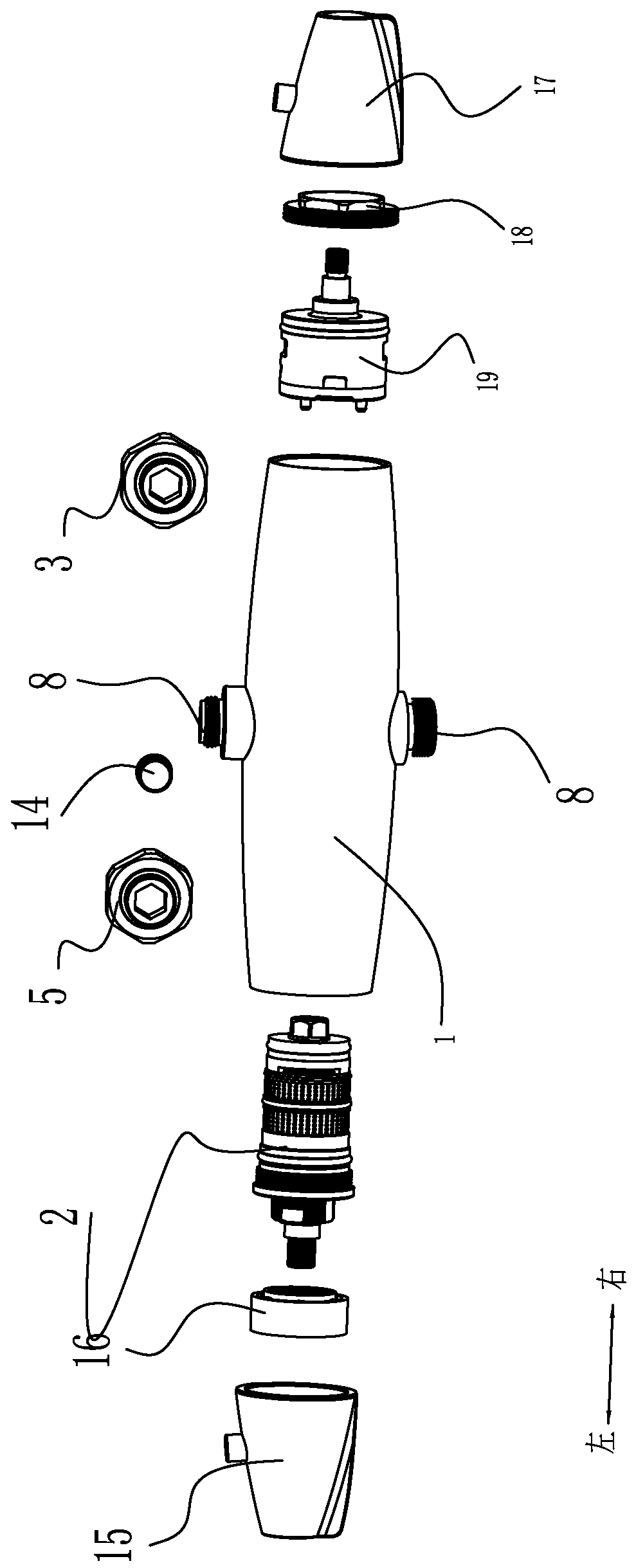

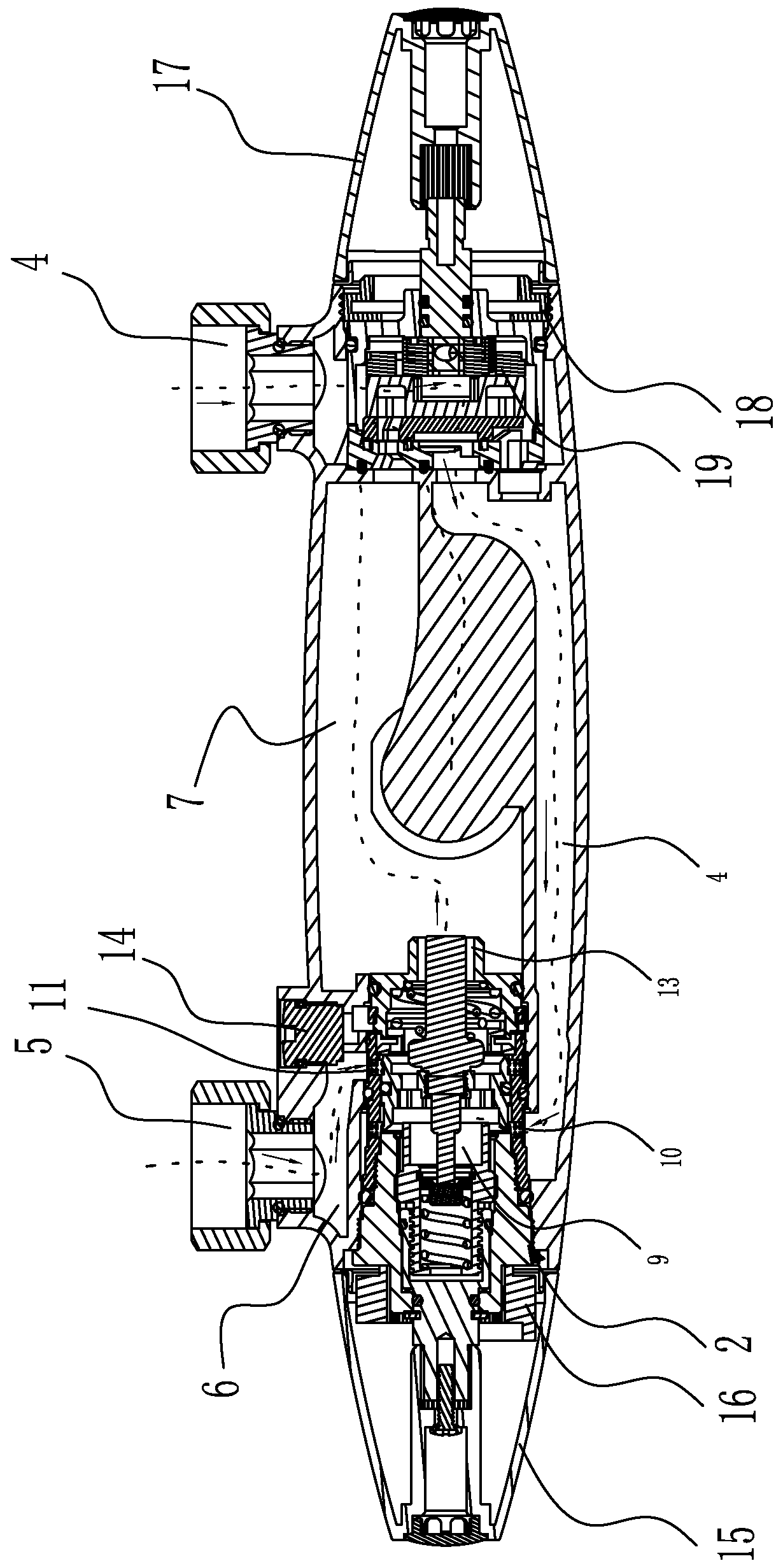

[0039] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the embodiment of the present invention.

[0040] A special thermostatic shower for a gas water heater, comprising a body 1 and a gas thermostatic valve core 2 installed on the body 1, a cold water inlet 3, a cold water flow channel 4, a hot water inlet 5, a hot water flow channel 6, a mixed water Chamber 7, mixed water outlet 8.

[0041] Wherein, the gas thermostatic valve core 2 has a valve core inner cavity 9, a valve core cold water inlet 10, a valve core hot water main inlet 11, a valve core hot water replenishment inlet 12, and a valve core mixed water outlet 13. The inlet 10, the hot water main inlet 11 of the spool, the hot water replenishment inlet 12 of the spool, and the mixed water outlet 13 of the spool are respectively connected to the inner cavity 9 of the spool; the cold water inlet 3 is connected to one end of the cold water channel 4, and the cold water flows The other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com