Gas water heater constant-temperature valve element

A technology of gas water heaters and thermostatic valve cores, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as failure to ignite and gas flameout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

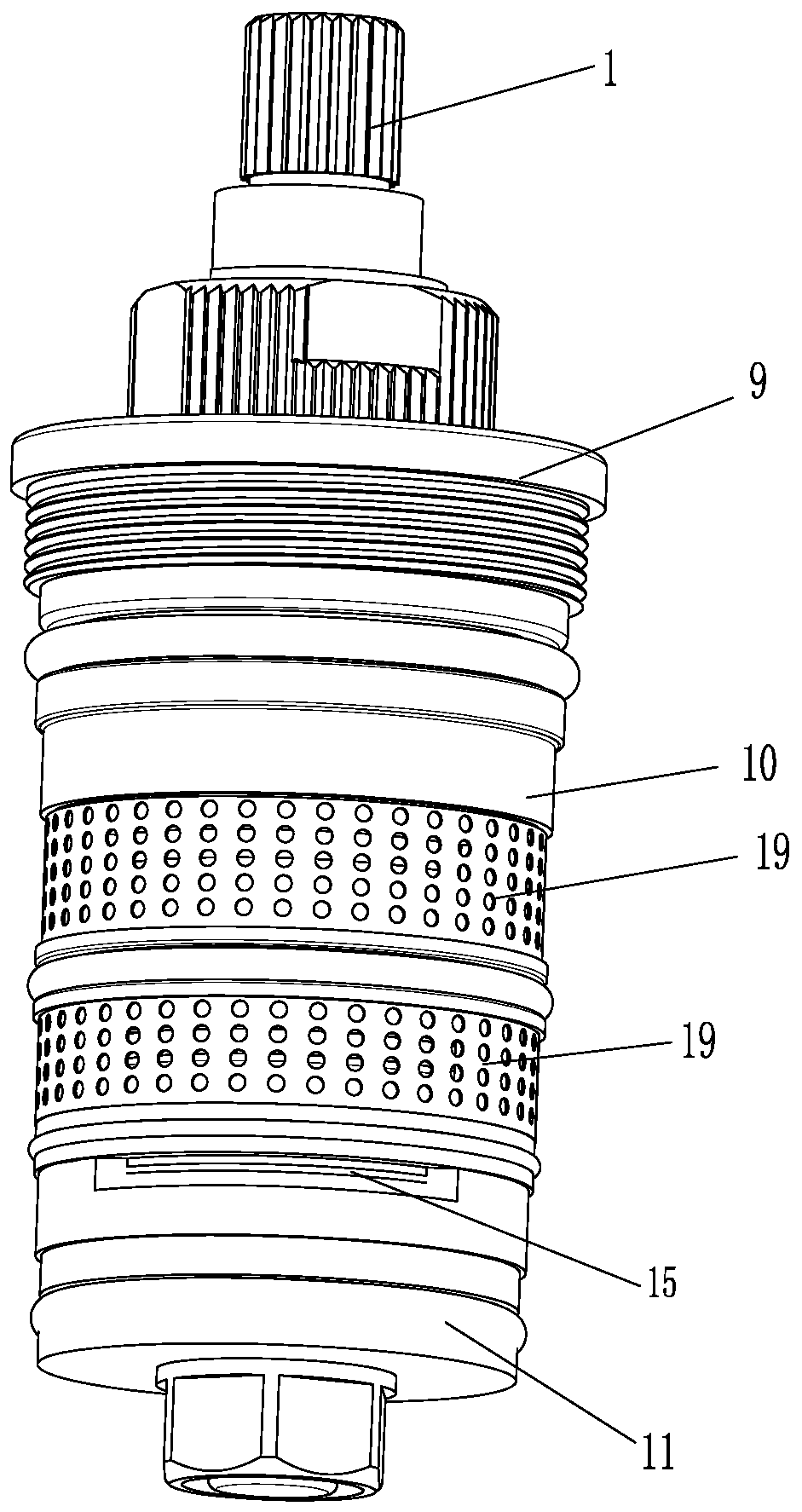

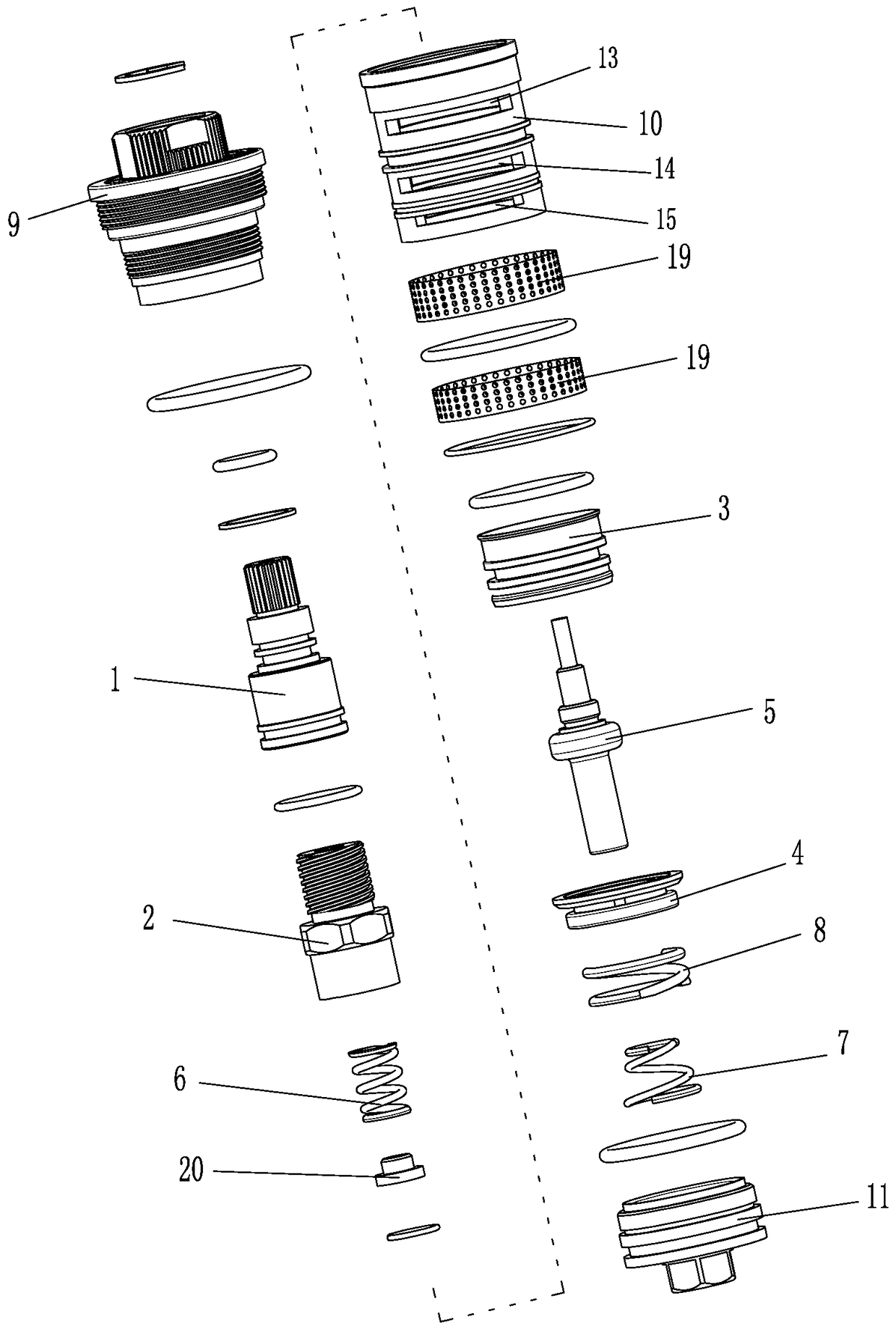

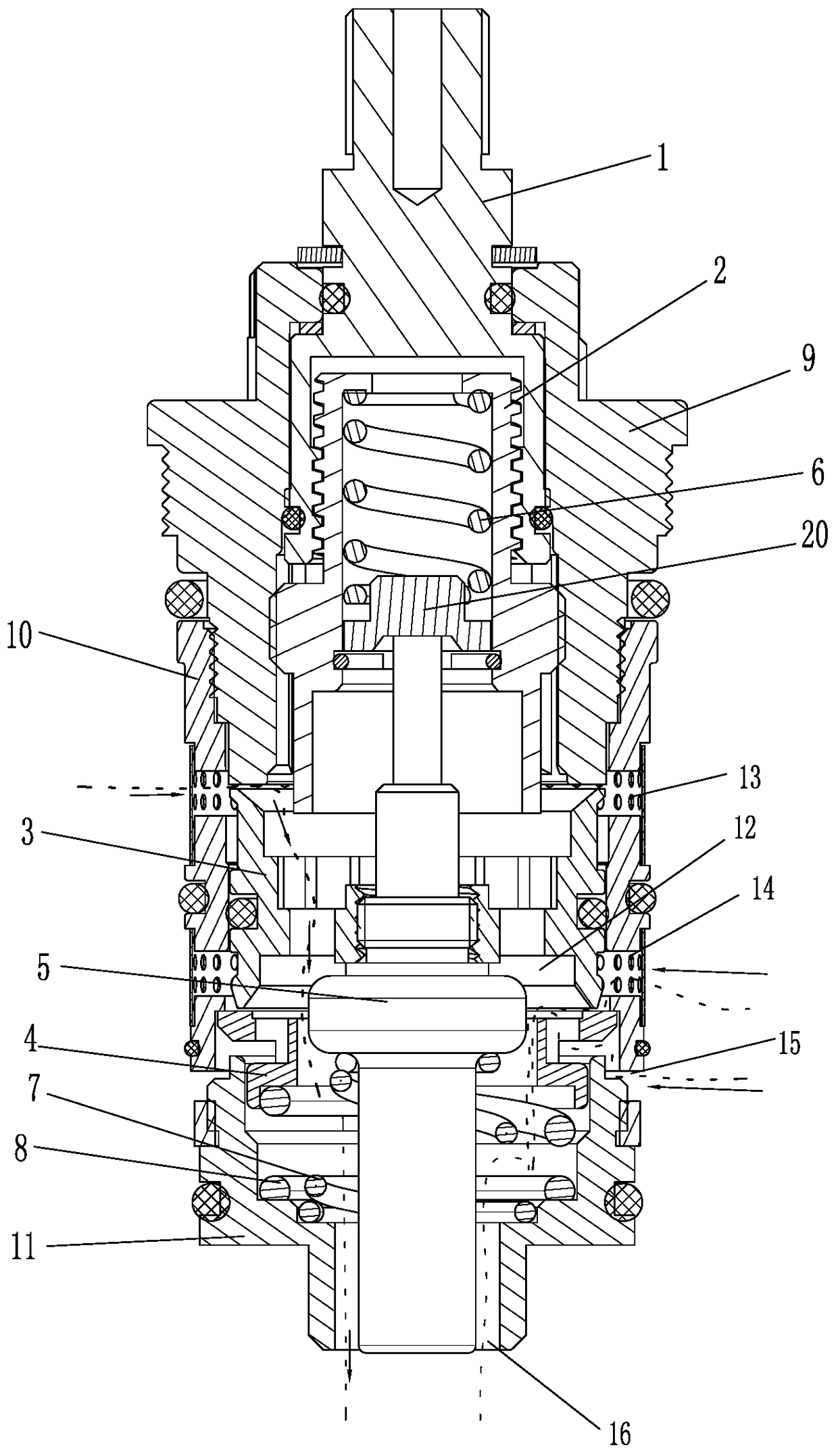

[0042] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the embodiment of the present invention.

[0043] A constant temperature valve core of a gas water heater, comprising a valve core housing and a rotating rod 1 installed in the valve core housing, a guide rod 2, a plunger 3, a plunger seat 4, a temperature bulb 5, a protection spring 6, and a working spring 7 And auxiliary spring 8; The upward combined force value of described working spring 7 and auxiliary spring 8 is greater than the downward force value of protective spring 6; The upward combined force value of described working spring 7 and auxiliary spring 8 is lower than protective spring 6 The force value is more than 10N.

[0044] Wherein, the spool housing includes an upper cover 9, a lower housing 10 and a bottom cover 11, the lower housing 10 is screw-fitted on the outer periphery of the upper cover 9, and the bottom cover 11 is assembled on the lower housing 10 the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com