Nozzle structure

一种结构体、喷嘴的技术,应用在铸造熔融物容器、制造工具、金属加工设备等方向,能够解决铸造时间延至很长时间等问题,达到容易卸下、抑制质量下降、高精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

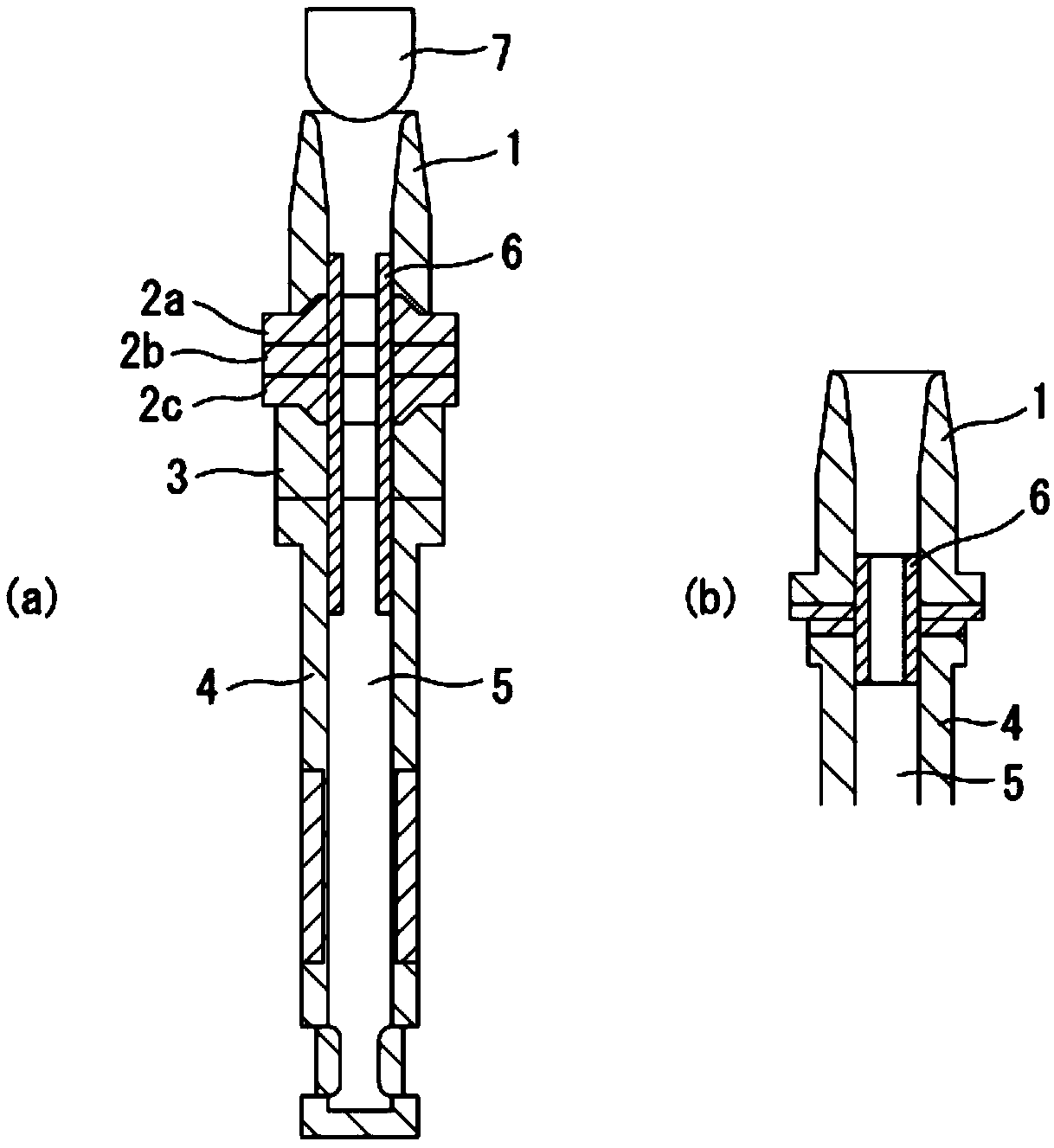

[0036] A typical form of the nozzle structure of the present invention with the largest number of divisions, that is, the number of joints, is an upper nozzle, a three-piece sliding nozzle plate (upper plate, middle plate, and lower plate), an intermediate nozzle, a lower nozzle, a dipping In the case of multiple refractory components such as nozzles. However, it is not necessary to be limited to this form, and the form which combined arbitrary 2 or more of each said refractory material may be sufficient. For example, figure 1 (a) is an example composed of upper nozzle 1, upper plate 2a, middle plate 2b, lower plate 2c, lower nozzle 3 and submerged nozzle 4, figure 1 (b) is an example constituted by the upper nozzle 1 and the submerged nozzle 4 . That is, the nozzle structure of the present invention is a nozzle structure for discharging molten steel provided with joints at one or more locations, the joints dividing and joining the molten steel discharge path having the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com