Expressage envelope and using method

An envelope and sealing plate technology, applied in the field of envelopes, can solve the problems that envelopes cannot be reused and cannot be automatically alarmed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

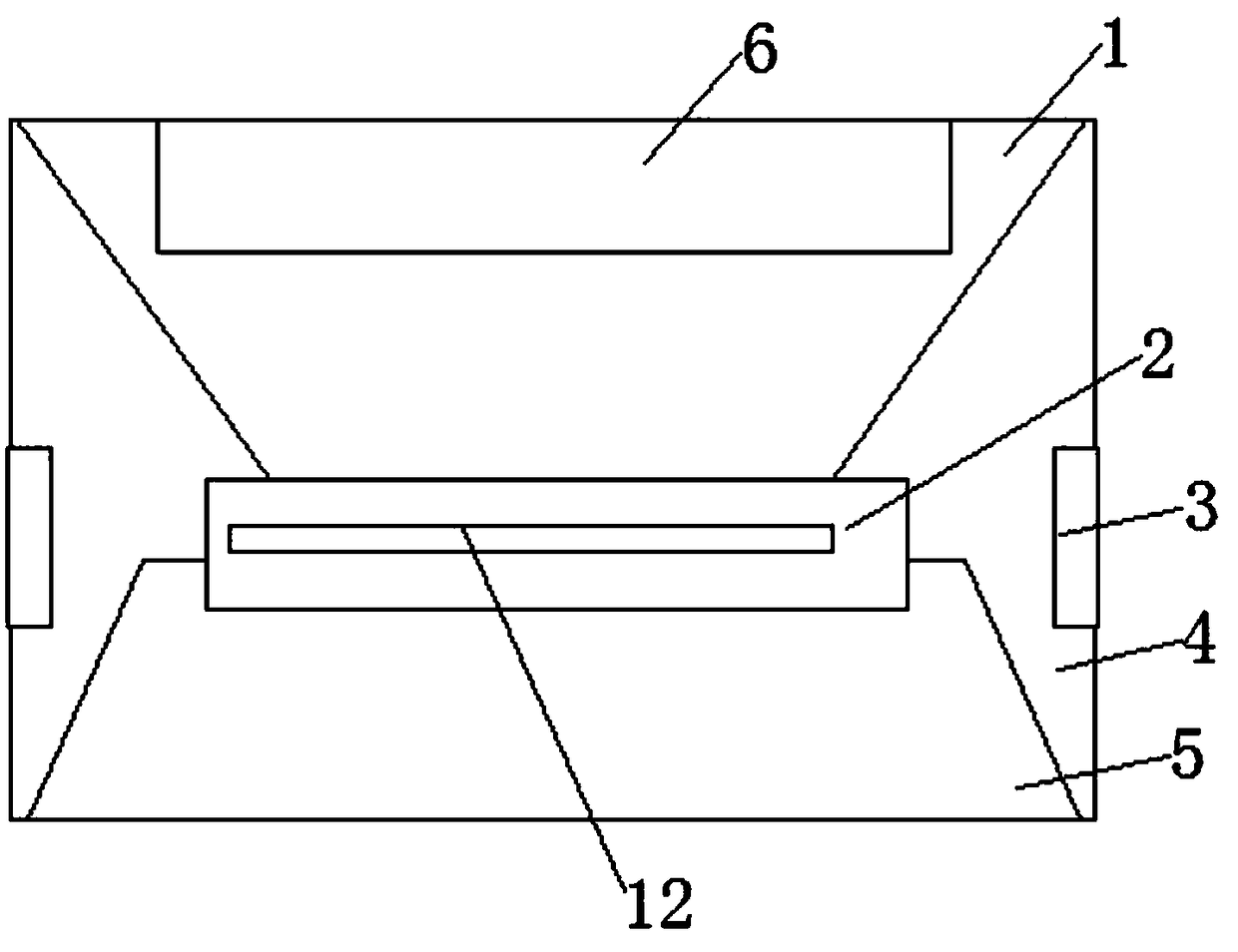

[0062] The express envelope of this embodiment 1 includes a main body 4, a first sealing plate 1 is folded at the upper edge of the main body 4, and a second sealing plate 5 is folded at the lower edge of the main body 4; A sealing member 2 is provided on the folded overlapping part of a sealing plate 1 and the second sealing plate 5; a first storage chamber 9 and a second storage chamber 10 are clamped in the main body 4; A central control unit 11 is clamped on the inner wall; the seal 2 is a first sealing structure or a second sealing structure;

[0063] The central control unit 11 includes an ARM controller 1104, a GPS positioning module 1101 and an alarm 1102; the GPS positioning module 1101 and the alarm 1102 are electrically connected to the ARM controller 1104; 11 is electrically connected with a storage battery 1103;

[0064] A wire breakage sensor 12 is bound to the seal 2, and the wire breakage sensor 12 is electrically connected to the ARM controller 1104; the alar...

Embodiment 2

[0070] Further, on the basis of embodiment 1:

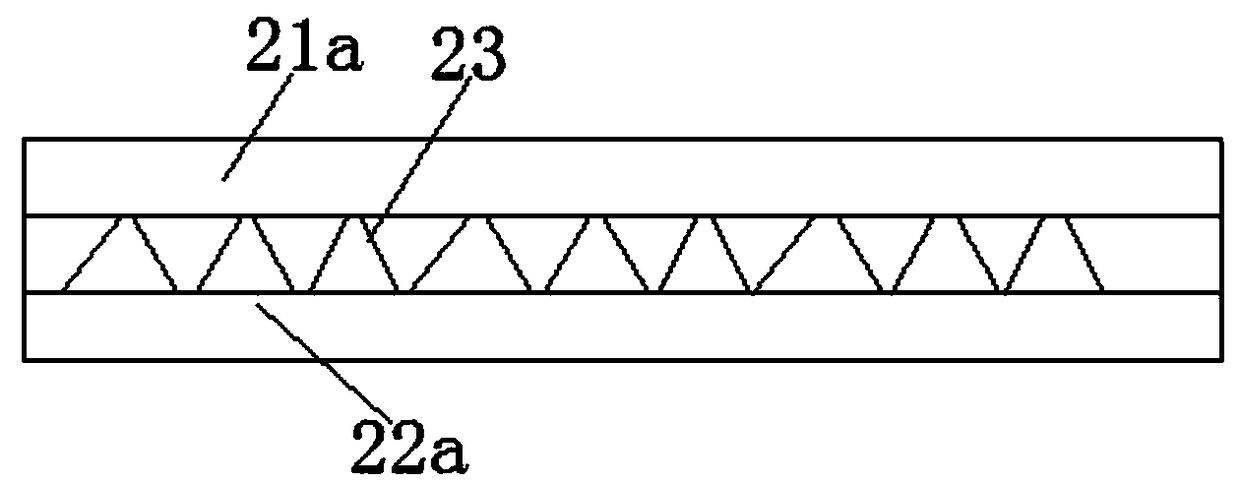

[0071] The first sealing structure includes a first connecting strip 21a bonded to the lower edge of the first sealing plate 1 and a second connecting strip 22a bonded to the upper edge of the second sealing plate 5;

[0072] Both the first connecting belt 21a and the second connecting belt 22a are strip-shaped; a slide fastener 23 is arranged between the first connecting belt 21a and the second connecting belt 22a, and the slide fastener 23 is used for Sewing or separating the first sealing plate 1 and the second sealing plate 5 .

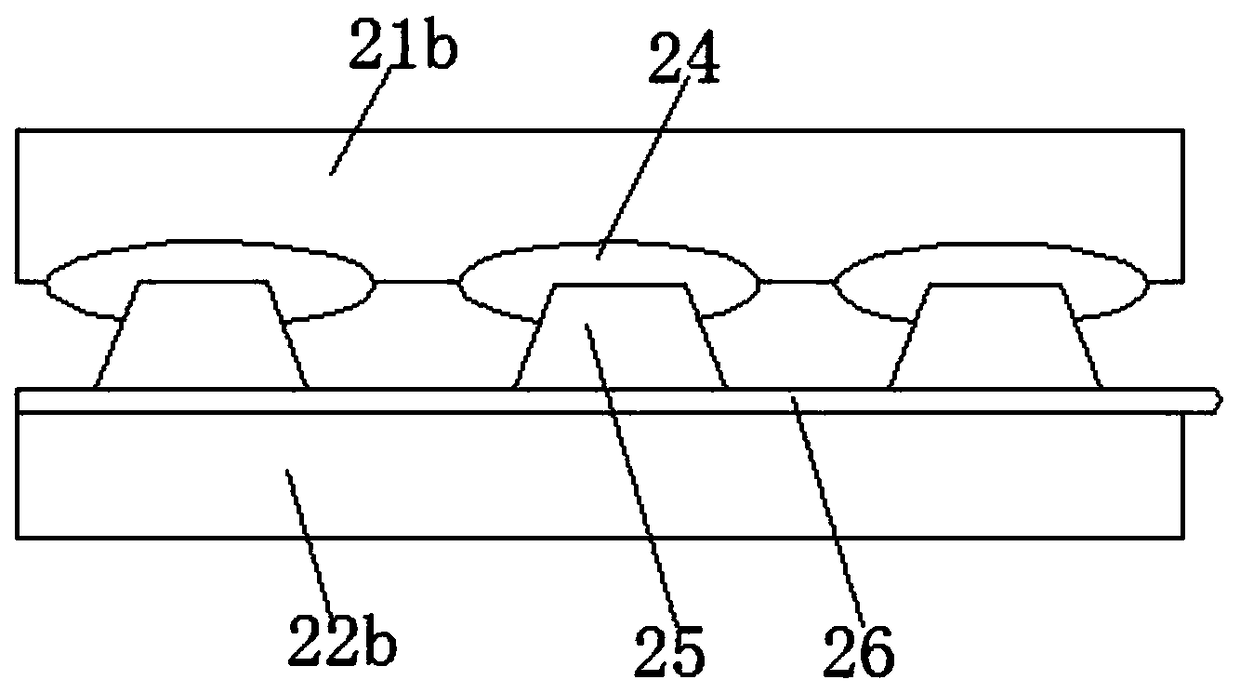

[0073] The second sealing structure includes a third connecting strip 21b bonded to the lower edge of the first sealing plate 1 and a fourth connecting strip 22b bonded to the upper edge of the second sealing plate 5;

[0074] A plurality of first magnet pieces 24 are clamped at the lower edge of the third connecting strip 21b;

[0075] On the upper edge of the fourth connection belt 22b, a round b...

Embodiment 3

[0088] Further, on the basis of embodiment 2:

[0089] A method of use, for the express envelope, comprising the steps of:

[0090] Step 1: Open the seal 2, place the mailed letter in the first storage room 9, buckle the sealing cover 91 on the upper end of the box 92; place the mailed object in the In the second storage room 10, fasten the first fastening plate 1009 and the second fastening plate 1010, fasten the first cardboard 1002 and the third cardboard 1005;

[0091] Step 2: Fold the first sealing plate 1 and the second sealing plate 5, seal the sealing member 2, and then place the broken wire sensor 12 on the sealing member 2;

[0092]Step 3: Put the two ends of the sealing strip in the fixed opening 3 respectively; the sealing strip is placed between the carrier frame 305 and the upper clamping block 302; the glue in the bonding groove 306 Tighten the lower side of the sealing strip; the spring 308 pushes the upper clamping block 302 to press the sealing strip downwa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap