Rubber roller placing frame of printer

A technology of rubber rollers and racks, applied to external frames, packaging, external accessories, etc., can solve problems such as inconvenient movement, unreasonable force, and poor adaptability, and achieve convenient adjustment, strong adaptability, and scientific force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

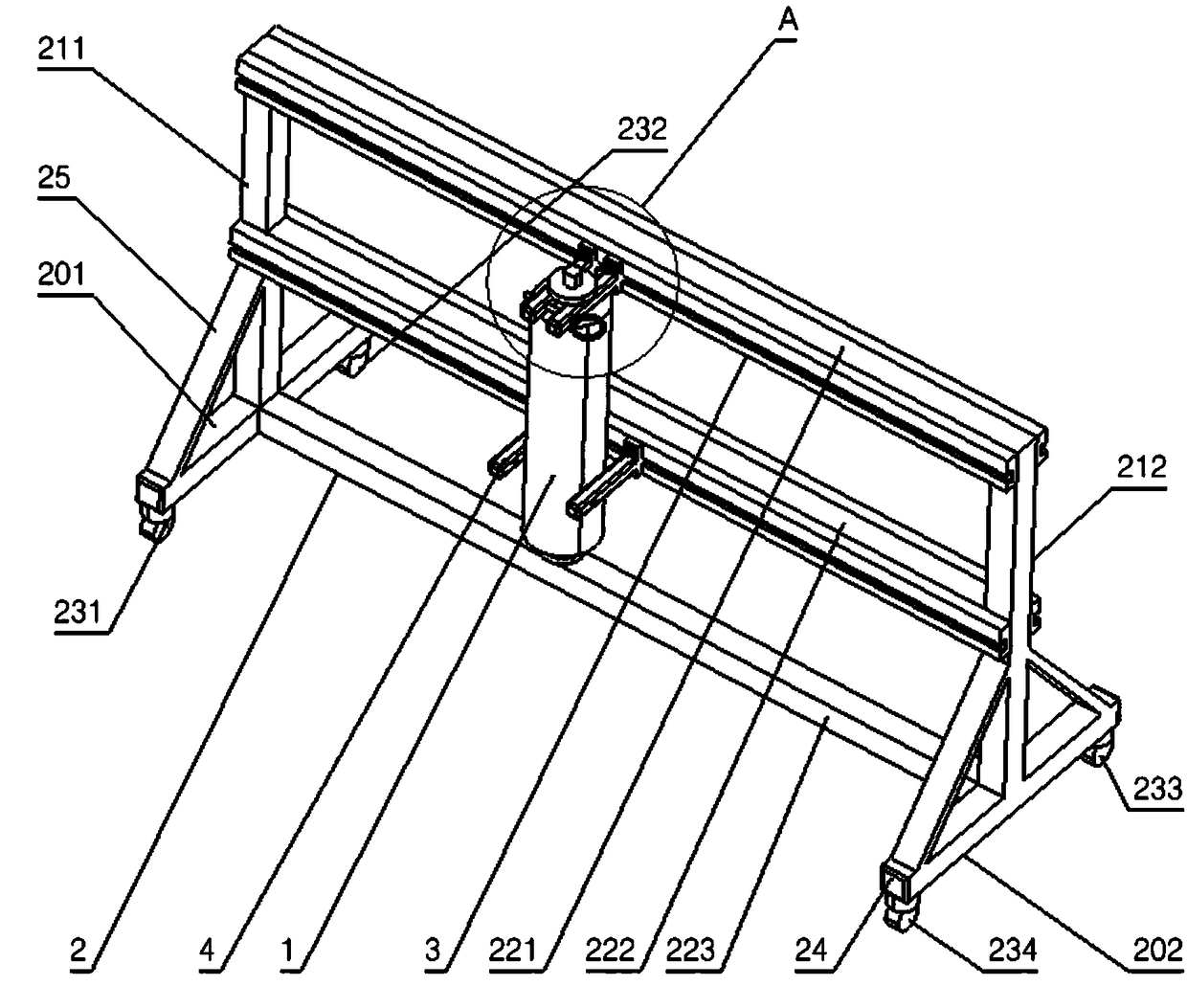

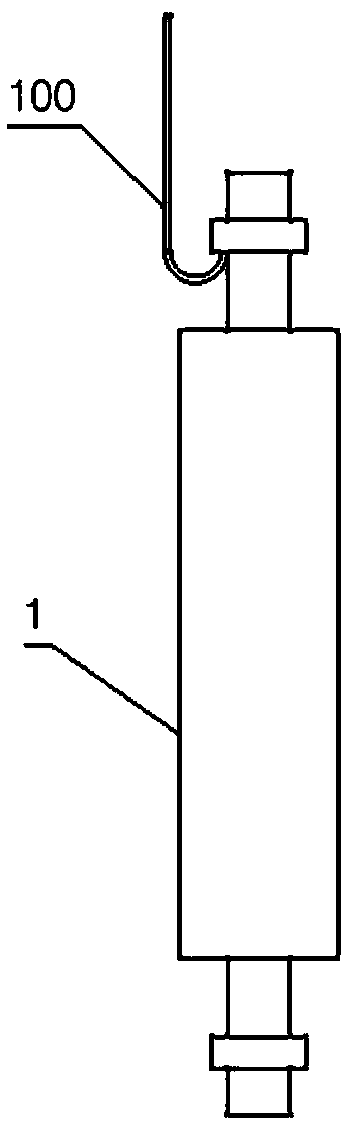

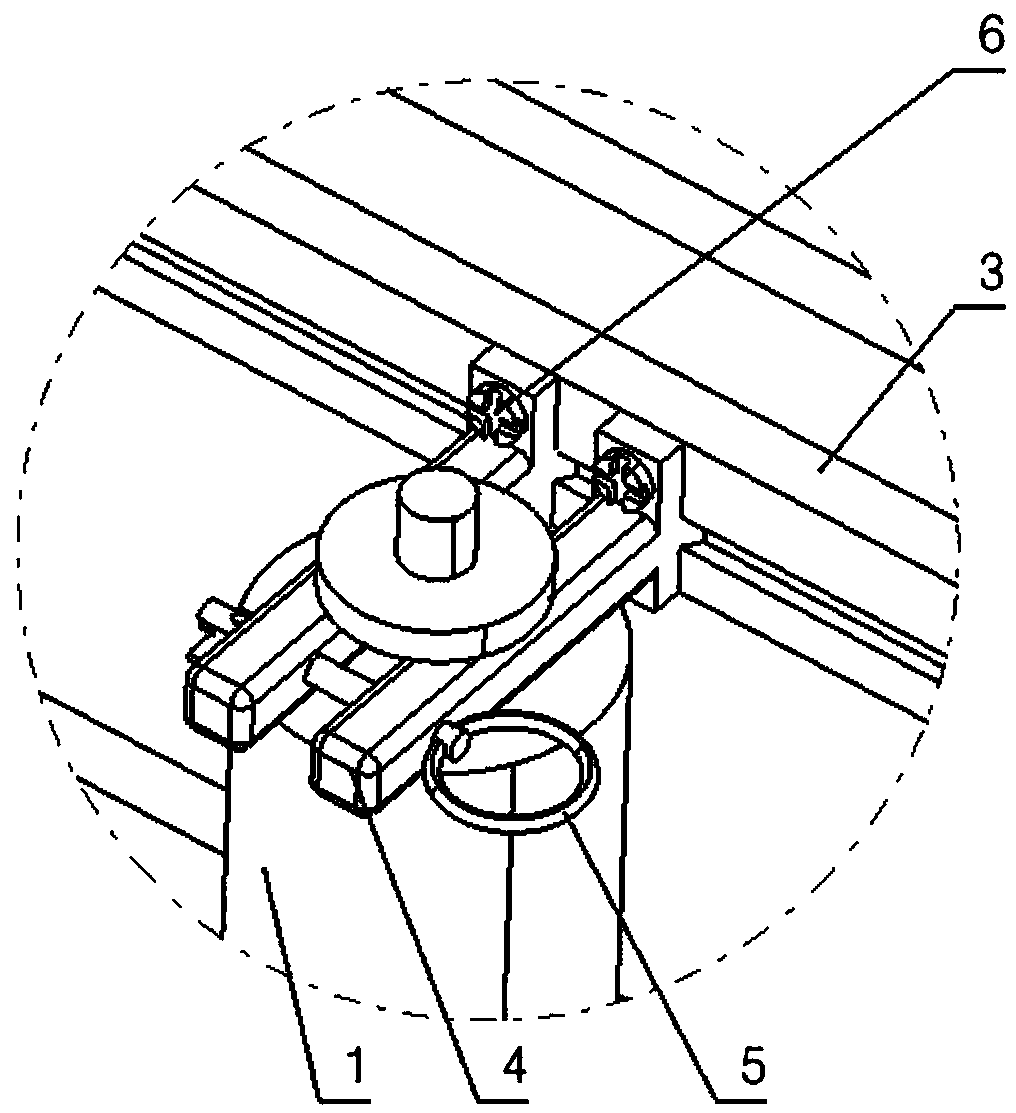

[0019] Embodiment 1 discloses a rubber roller placement frame for a printing machine and shows a situation where a rubber roller is fixedly placed, such as figure 1 with image 3 shown. The printing machine rubber roller placement frame includes a main body support 2 , a slide rail 3 , a sliding support arm 4 , a safety pin 5 and a set screw 6 . Wherein, the main frame 2 is composed of two bottom longitudinal beams 201 and 202 arranged in parallel, two uprights 211 and uprights 212 respectively connected to the midpoint of the upper surface of the bottom longitudinal beams, and one top beam connected between the tops of the uprights. 221 and a middle beam 222 connected between the middle of the columns and a ground beam 223 connected between the midpoints of the bottom longitudinal beams are welded. Bottom longitudinal beam 201 and bottom longitudinal beam 202 bottom two ends are installed caster 231, caster 232, caster 233 and caster 234 by screw. The slide rail 3 is fixe...

Embodiment 2

[0022] Embodiment 2 discloses a rack for placing a rubber roller of a printing machine and shows a situation in which a rubber roller is fixedly placed. The printing machine rubber roller placement frame includes a main body support 2 , a slide rail 3 , a sliding support arm 4 , a safety pin 5 and a set screw 6 . Wherein, the main body support consists of two bottom longitudinal beams 201 and 202 arranged in parallel, two uprights 211 and uprights 212 respectively connected to the midpoint of the upper surface of the bottom side beams, and one top beam 221 connected between the tops of the uprights. It is welded with a middle beam 222 connected between the middle parts of the uprights and a ground beam 223 connected between the middle points of the bottom longitudinal beams. Bottom longitudinal beam 201 and bottom longitudinal beam 202 bottom two ends are installed caster 231, caster 232, caster 233 and caster 234 by screw. The slide rail 3 is fixedly installed on the sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com