Self-centering small-caliber ammunition primer press-fitting mechanism

A small-caliber, self-centering technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., to achieve the effect of easy and accurate pressing, good movement performance, and smooth movement of meshing gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

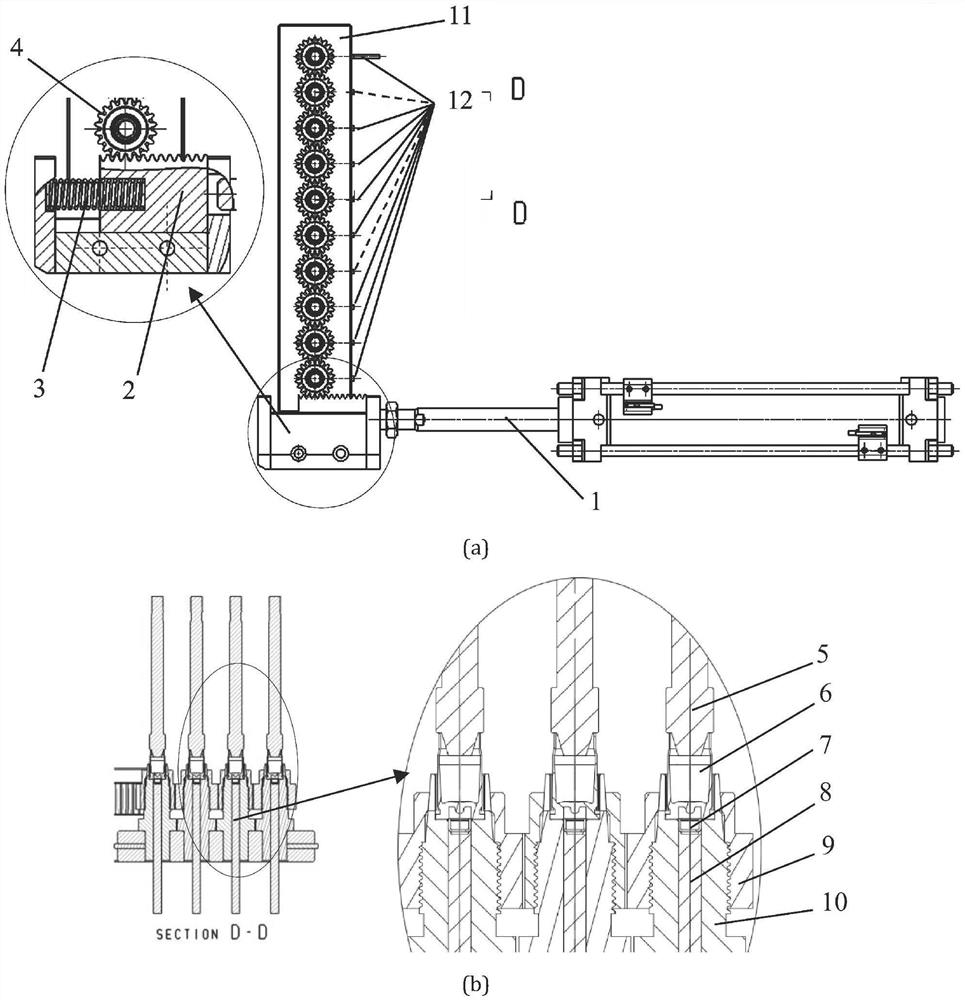

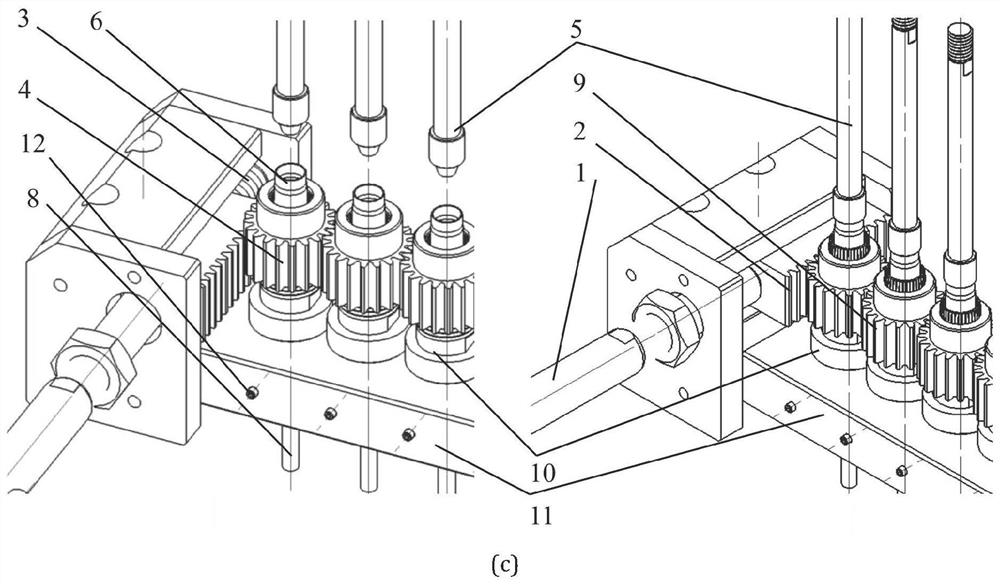

[0022] Such as figure 1 As shown, this embodiment relates to a small-caliber ammunition primer press-fitting mechanism with the self-centering function of the push-pull gear, including: several primer press-fit units arranged side by side and meshing with each other and a drive connected to one primer press-fit unit mechanism, wherein: the primer pressing unit is rotatably arranged on the fixed base plate, and the reciprocating motion of the driving mechanism drives each primer pressing unit to rotate.

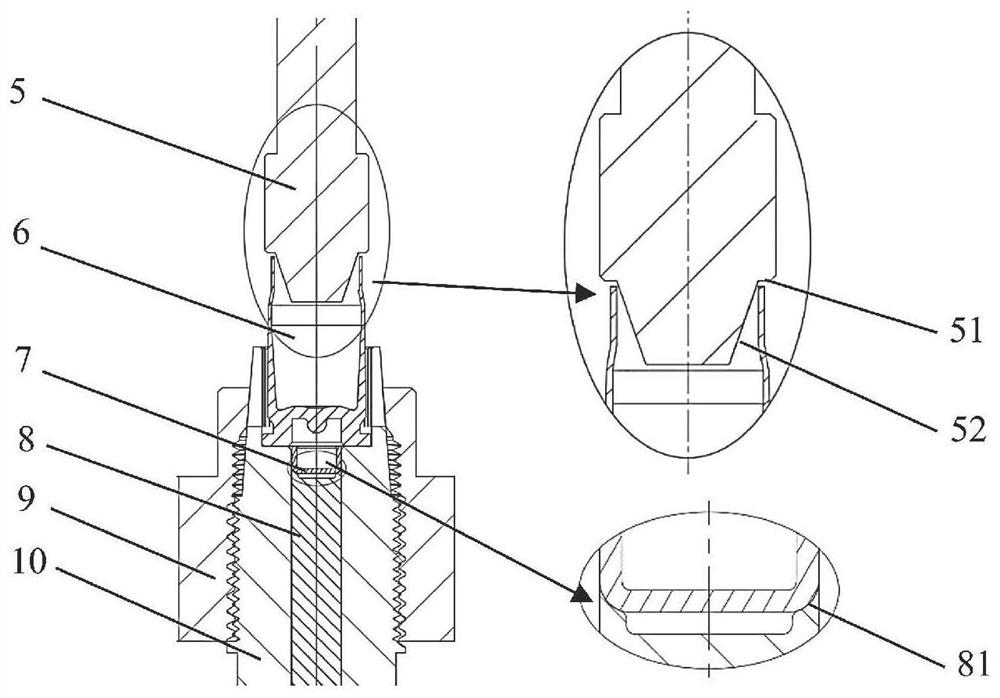

[0023] The primer pressing unit includes: a pressure rod 5 and a push rod 8 arranged oppositely up and down, an assembly flange 10 and a pusher gear 9 arranged outside the push rod 8 in turn, wherein: one end of the cartridge case 6 is sleeved on the pressure rod 5 end, the other end is set in the assembly flange 10, and the primer 7 is set on the top of the push rod 8.

[0024] Such as figure 2 As shown, the bottom of the pressing rod 5 is provided with a taper 52 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com