Garden brush cutter

A technology for brush cutters and gardens, which is applied to harvesters, cutters, agricultural machinery and implements, etc. It can solve problems such as bumps and collisions, damage to brush cutters, time-consuming and labor-intensive problems, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

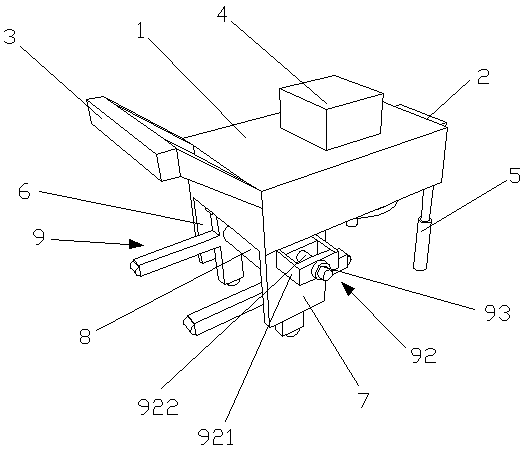

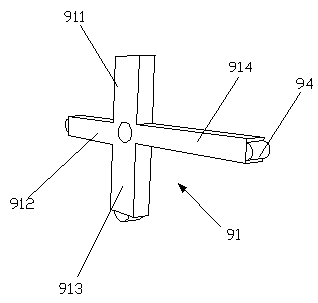

[0021] like Figure 1-2 Shown, a kind of garden brush cutter of the present invention comprises brush cutter body 1, and brush cutter body 1 is a rectangular structure, and the front end of brush cutter body 1 is provided with weeding device 2, and the rear end of brush cutter body 1 is provided with Handrail 3, the top of the brush cutter body 1 is provided with a power control device 4, the front end of the brush cutter body 1 is provided with several front support columns 5, and the rear end of the brush cutter body 1 is provided with a first rear support plate 6 and a second rear support Plate 7, the length of the first rear support plate 6 and the second rear support plate 7 is the same, and the first rear support plate 6 and the second rear support plate 7 are symmetrically arranged on the rear end of the brush cutter body 1, the first rear support plate 6 and the second rear support plate 7 are also provided with a rotating shaft 8, and the two ends of the rotating shaf...

Embodiment 2

[0023]The brush cutting body 1 has a rectangular structure, the front end of the brush cutting body 1 is provided with a grass pulling device 2, the rear end of the brush cutting body 1 is provided with a handrail 3, and the top of the brush cutting body 1 is provided with a power control device 4. The front end of 1 is provided with several front support columns 5, and the rear end of brush cutter body 1 is provided with the first rear support plate 6 and the second rear support plate 7, and the length of the first rear support plate 6 and the second rear support plate 7 is the same , and the first rear support plate 6 and the second rear support plate 7 are symmetrically arranged on the rear end of the brush cutter body 1, and a rotating shaft 8 is also arranged between the first rear support plate 6 and the second rear support plate 7, and the rotating shaft 8 The two ends are movable respectively in the first rear support plate 6 and the second rear support plate 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com