Gantry type laser processing cutting device

A laser processing and cutting device technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor flexibility and freedom of laser cutting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

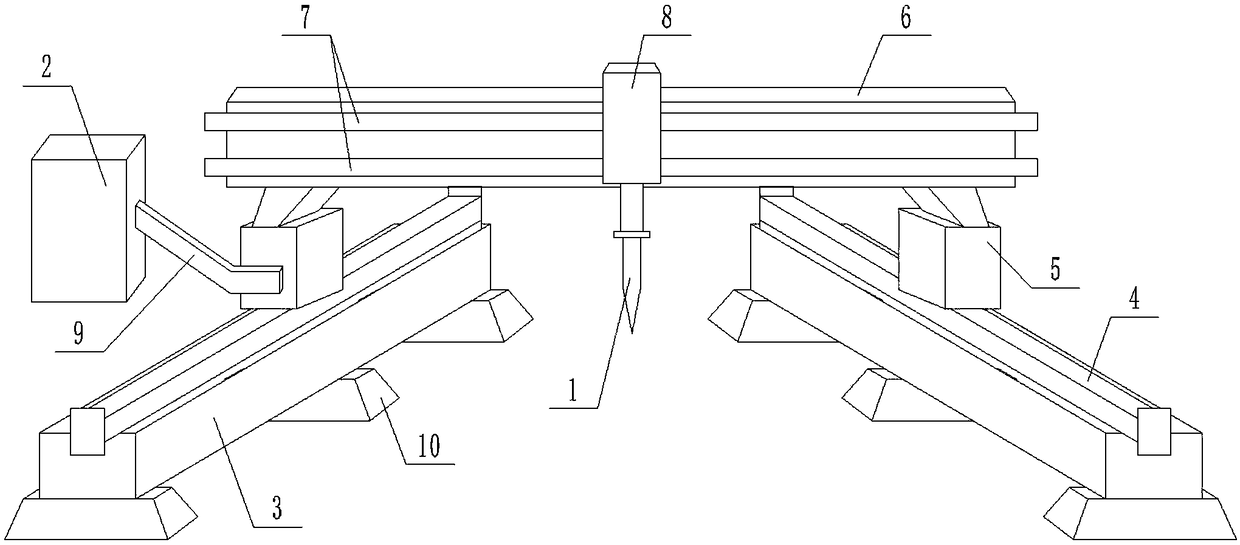

[0018] Such as figure 1 A gantry-type laser processing and cutting device shown includes a laser cutter 1, a numerical control box 2 for controlling the laser cutter 1, and two supporting legs 3, each of which is provided with a first A guide rail 4, the long axes of the two first guide rails 4 are parallel to each other, the first slide block 5 matching the first guide rail 4 is arranged on the first guide rail 4, and a gantry beam is erected between the two first slide blocks 5 6. Two second guide rails 7 distributed up and down are arranged on the gantry beam 6, and the long axis of the second guide rail 7 is perpendicular to the long axis of the first guide rail 4; The second sliding block 8 that is slidably connected, is fixedly connected with the laser cutter 1 on the second sliding block 8, and the working end of the laser cutting knife 1 is vertically downward; the first sliding block 5, the second Slide block 8 is all controlled by described numerical control box 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com