Heat insulation method of electric water kettle

A technology of electric kettle and water temperature, which is applied to water boiling utensils, cooking utensils, household appliances, etc. It can solve the problems of water temperature influence, poor heat preservation effect, and low accuracy of temperature measurement scheme, and achieve the effect of improving heat preservation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

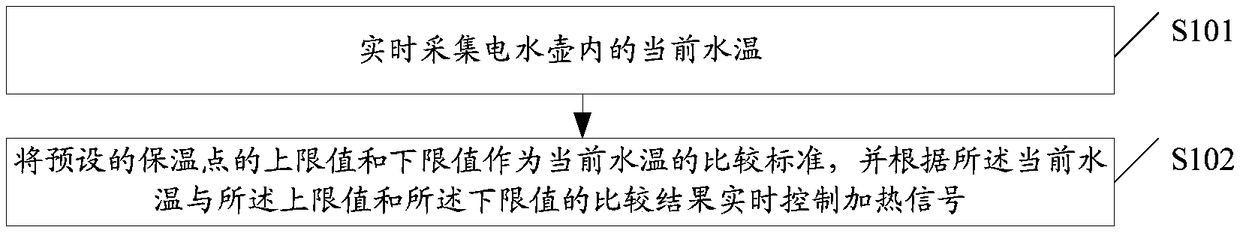

[0057] A kind of insulation method of electric kettle, such as figure 1 As shown, the method may include S01-S102:

[0058] S101. Real-time collection of the current water temperature T in the electric kettle C ;

[0059] S02. Set the preset heat preservation point T K The upper and lower limits of the current water temperature T C The comparison standard and according to the current water temperature T C The heating signal is controlled in real time by the comparison result with the upper limit value and the lower limit value.

[0060] In the embodiment of the present invention, in order to achieve the heat preservation effect, it is necessary to judge the water temperature in time, and judge the heat preservation effect by comparing the current water temperature with the set heat preservation point. In the embodiment of the present invention, the holding point T K The upper and lower limits of the current water temperature T C The comparative standard adopts double st...

Embodiment 2

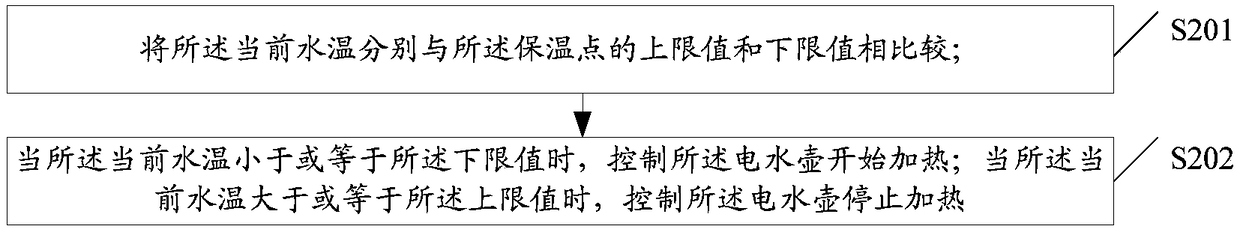

[0063] In this embodiment, on the basis of Embodiment 1, according to the current water temperature T C The scheme of controlling the heating signal in real time with the comparison result of the upper limit value and the lower limit value is introduced in detail.

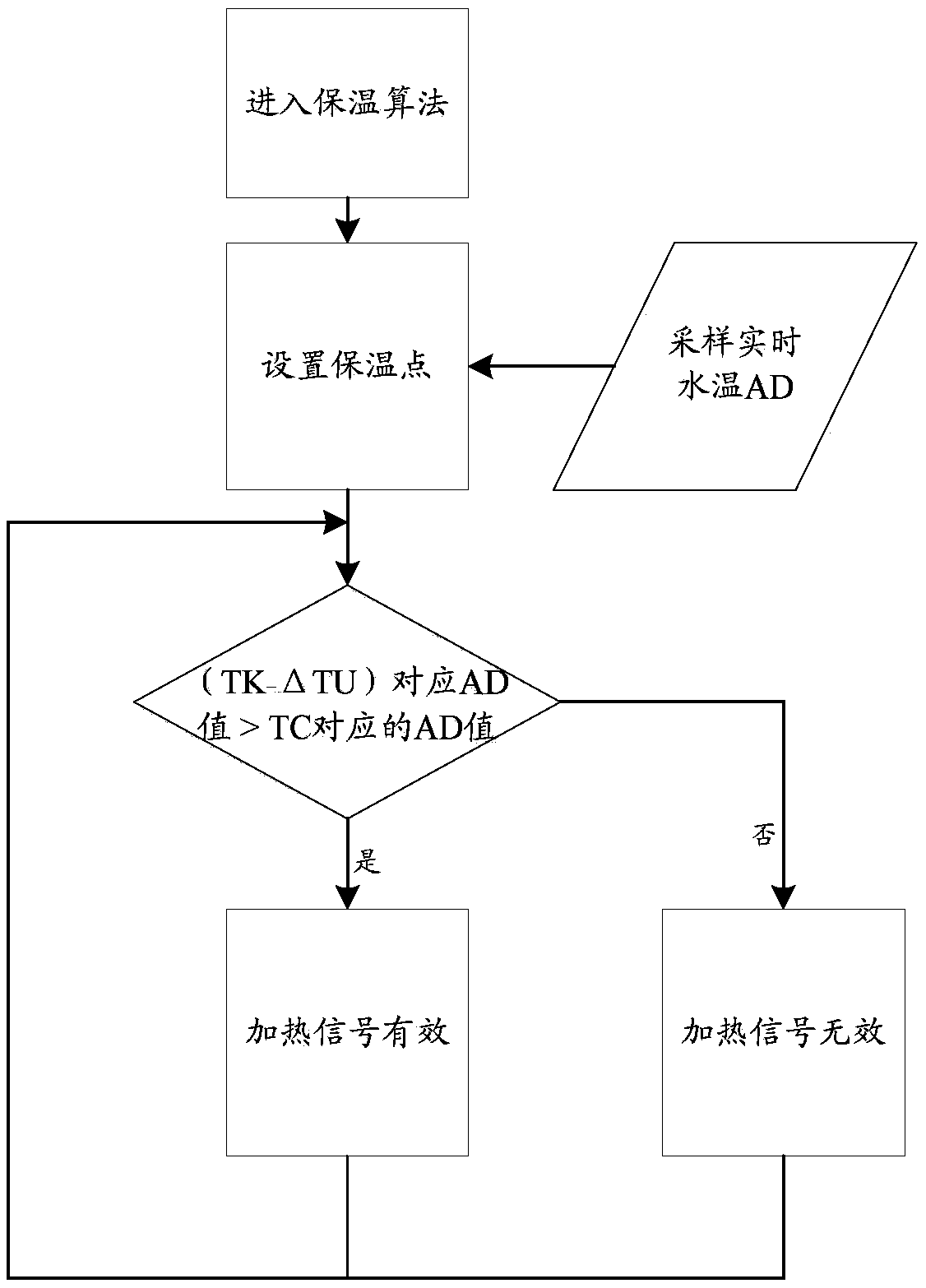

[0064] Optionally, as in figure 2 , image 3 shown, according to the current water temperature T C The real-time control of the heating signal based on the comparison result with the upper limit value and the lower limit value may include S201-S202:

[0065] S201. Set the current water temperature T C Respectively with the holding point T K Compare the upper limit value with the lower limit value;

[0066] S202. When the current water temperature T C When it is less than or equal to the lower limit value, control the electric kettle to start heating; when the current water temperature T C When greater than or equal to the upper limit, control the electric kettle to stop heating.

[0067] Optionally, the up...

Embodiment 3

[0078] In this embodiment, on the basis of the second embodiment, the upper limit fluctuation value ΔT U and the lower limit fluctuation value ΔT D The value of is further limited.

[0079] Optionally, the upper limit fluctuation value ΔT U and the lower limit fluctuation value ΔT D Can include: 2-5 AD values respectively.

[0080] In the embodiment of the present invention, in order to achieve the heat preservation effect, it is necessary to judge the water temperature in time, and judge the heat preservation effect by comparing the current water temperature with the set heat preservation point. And if the insulation range is set relatively large, that is, ΔT U and ΔT D If it is too large, the heat preservation accuracy will be very poor, which means that the heat preservation effect is poor; but if the ΔT U and ΔT D If the setting is small, the frequency of the heat preservation power will be high, which will increase the power consumption, but will improve the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com