Semi-solid continuous pulping system

A semi-solid, pulping technology, applied in the field of semi-solid preparation, can solve the problems of excessively large volume of the holding furnace, high cost, low heat preservation precision, etc., and achieve the effects of simple operation, reduction of preparation cost and saving of pulping time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

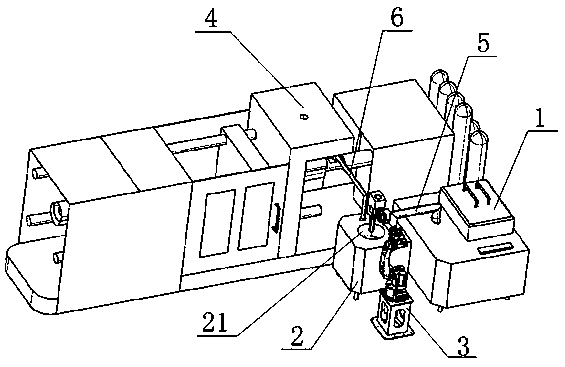

[0027] Refer to attached Figure 1-2 , a semi-solid continuous pulping system, comprising a large quantitative holding furnace 1, a small quantitative holding furnace 2, a stirring device 3 and a die-casting island 4, between the large quantitative holding furnace 1 and the small quantitative holding furnace 2 An extraction pipeline 5, and a delivery pipeline 6 is provided between the small quantitative holding furnace 2 and the die-casting island 4.

[0028] The volume of the large quantitative holding furnace 1 is at least 2 times of the volume of the small quantitative holding furnace 2, the extraction pipeline 5 and the delivery pipeline 6 are provided with quantitative pumps, and the small quantitative holding furnace 2 tops are equipped with There is an opening 21, and the opening 21 is matched with the stirring rod 31 of the stirring device 3, so that the stirring rod 31 is inserted into the small quantitative holding furnace 2, and the stirring rod 31 can continuously ...

Embodiment 2

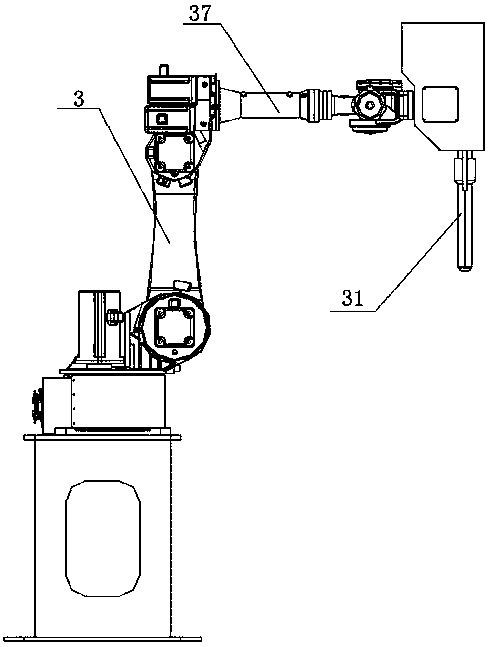

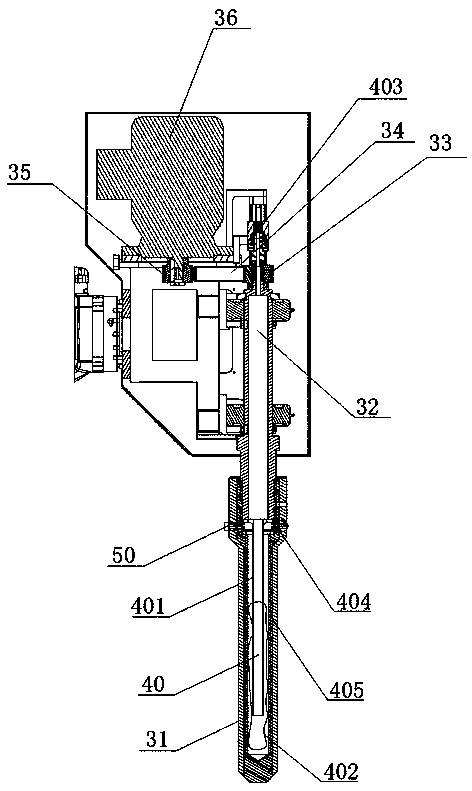

[0032] Refer to attached Figure 2-3 , a stirring device 3 is provided next to the small quantitative holding furnace 2. In the present embodiment, the stirring device 3 used includes a stirring rod 31, and one end of the stirring rod 31 is provided with a rotating shaft 32, and a limiting structure is provided on the rotating shaft 32, so that The rotating shaft 32 can only rotate and cannot move. The end of the rotating shaft 32 is provided with a rotating shaft driven wheel 33. The rotating shaft driven wheel 33 is connected to the rotating shaft driving wheel 35 through the rotating shaft driving link synchronous belt 34. The rotating shaft driving wheel 35 is fixedly connected to the driving motor 36 driving end, a mechanical arm 37 is provided on one side of the stirring rod 31, and the stirring rod 31 is driven by the mechanical arm 37;

[0033] The inside of the stirring rod 31 is provided with a cavity, the cavity is provided with a gas-liquid cooling structure 40, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com