Wet-process dust removal device

A technology for wet dust removal and box body, which is applied in combination devices, separation methods, chemical instruments and methods, etc., can solve the problems of low dust filtration efficiency and easy blockage of the filter screen, and achieves a smart structure, reduces labor burden, and is easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

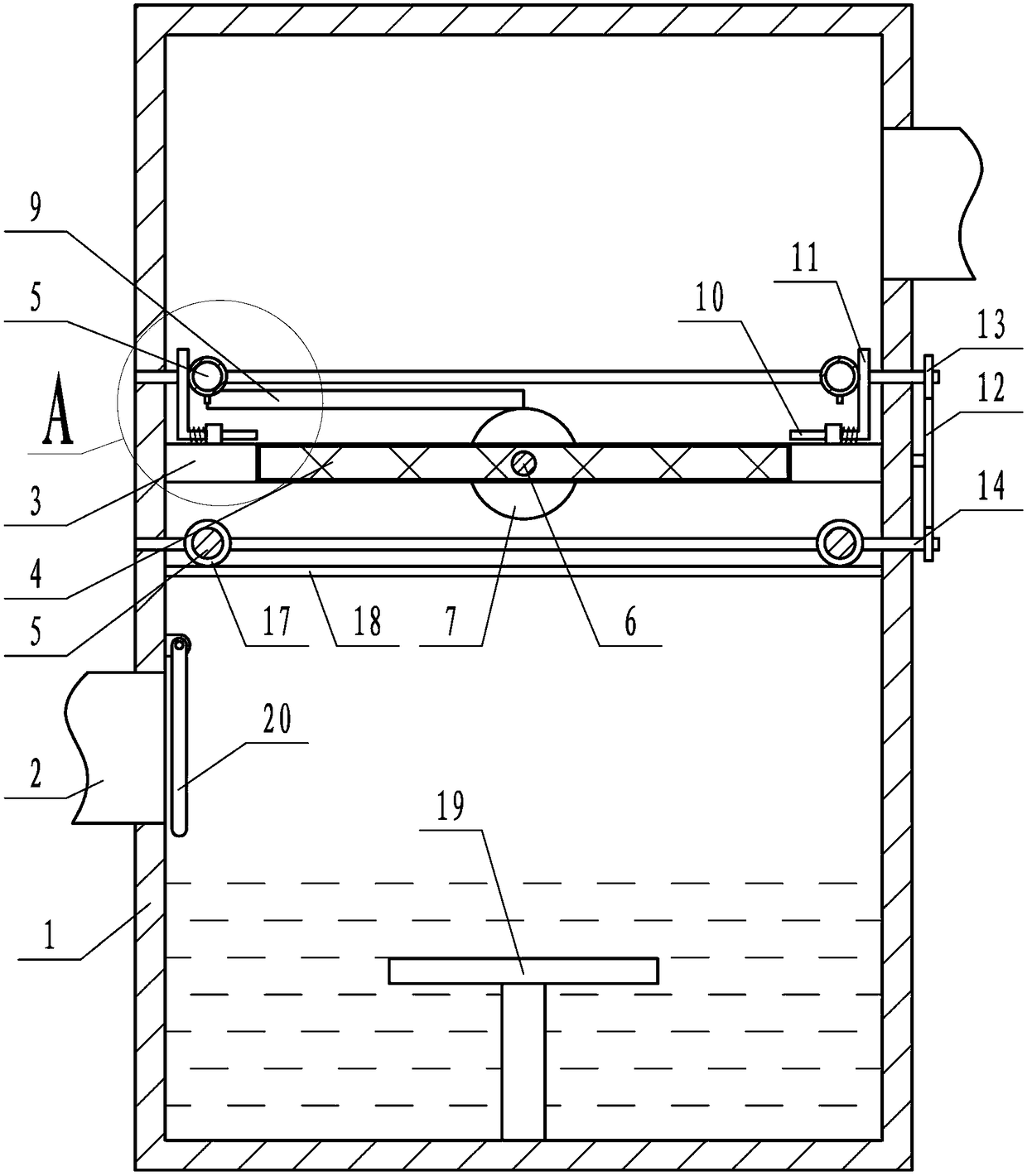

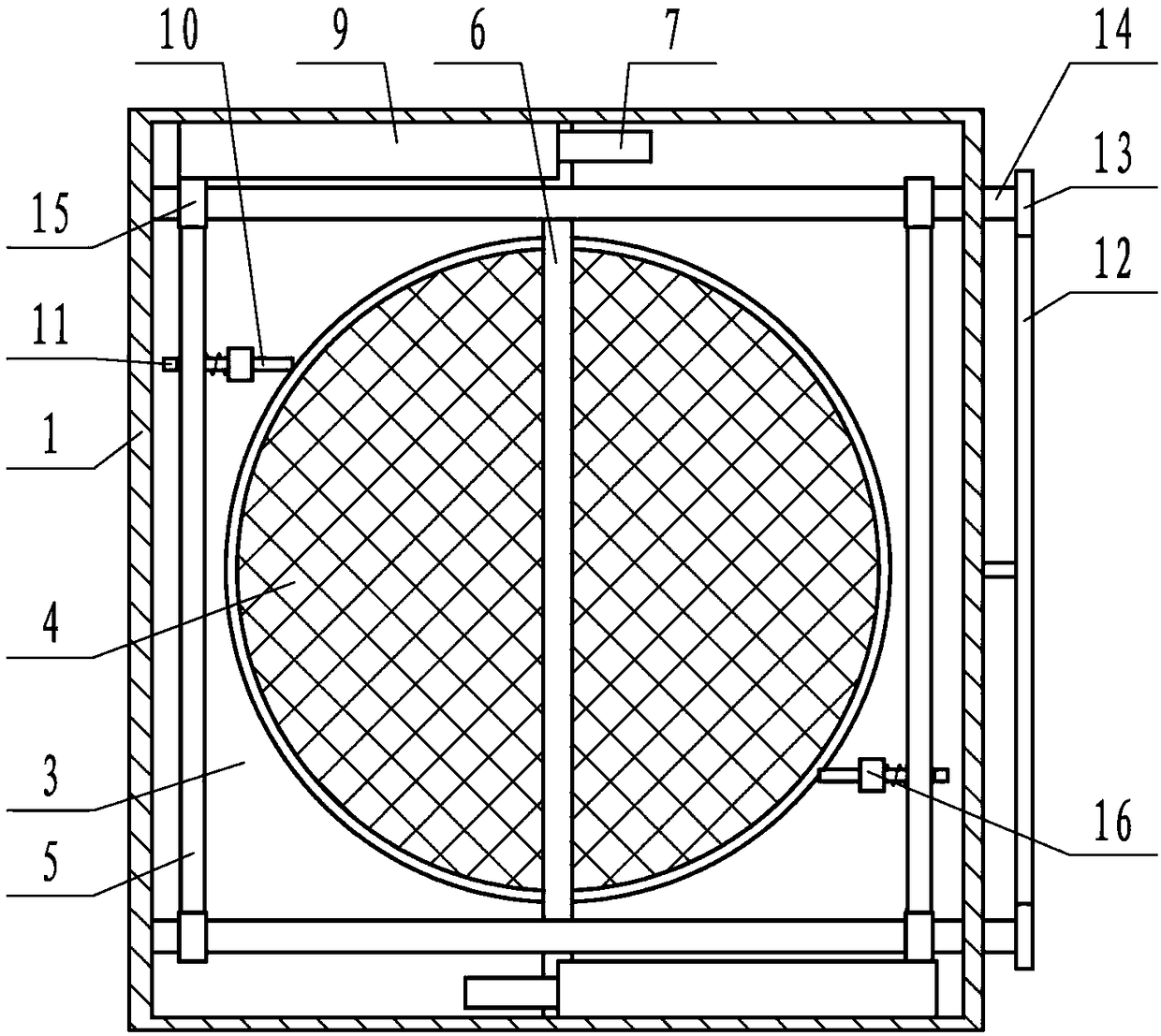

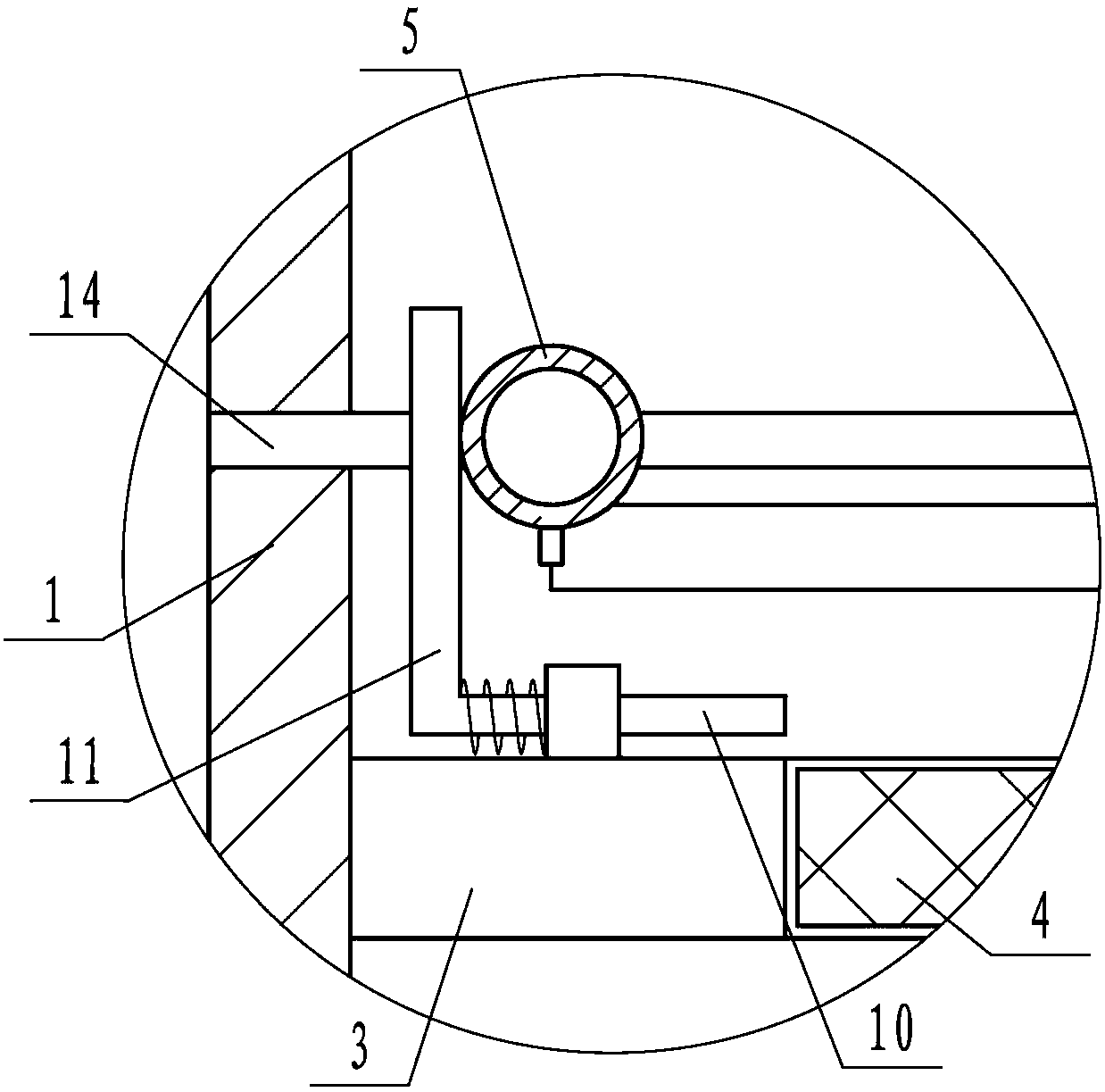

[0014] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

[0015] by Figure 1 to Figure 6 Given that the present invention includes a box body 1, two through holes 2 arranged up and down are opened on the box body 1, a horizontal baffle 3 located between the two through holes 2 is installed in the box body 1, and the center of the baffle 3 is installed Rotatable support rod 6, the support rod 6 is placed in the front and rear direction, the support rod 6 is equipped with a filter 4 that can rotate with the support rod 6; the upper and lower sides of the filter 4 have two in the same direction as the support rod 6 and can be left and right The moving shaft 5, the left and right shafts 5 can be synchronized to the middle and reset; the upper shaft 5 is hollow, and the outer edge surface is evenly distributed with multiple nozzles; the lower shaft 5 is provided with energy Brushes in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com