InstaLLing and fixing structure of rear combined Lamp

A fixed structure, rear combination lamp technology, applied in the direction of signal devices, transportation and packaging, optical signals, etc., can solve the problems of gap and surface difference, and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

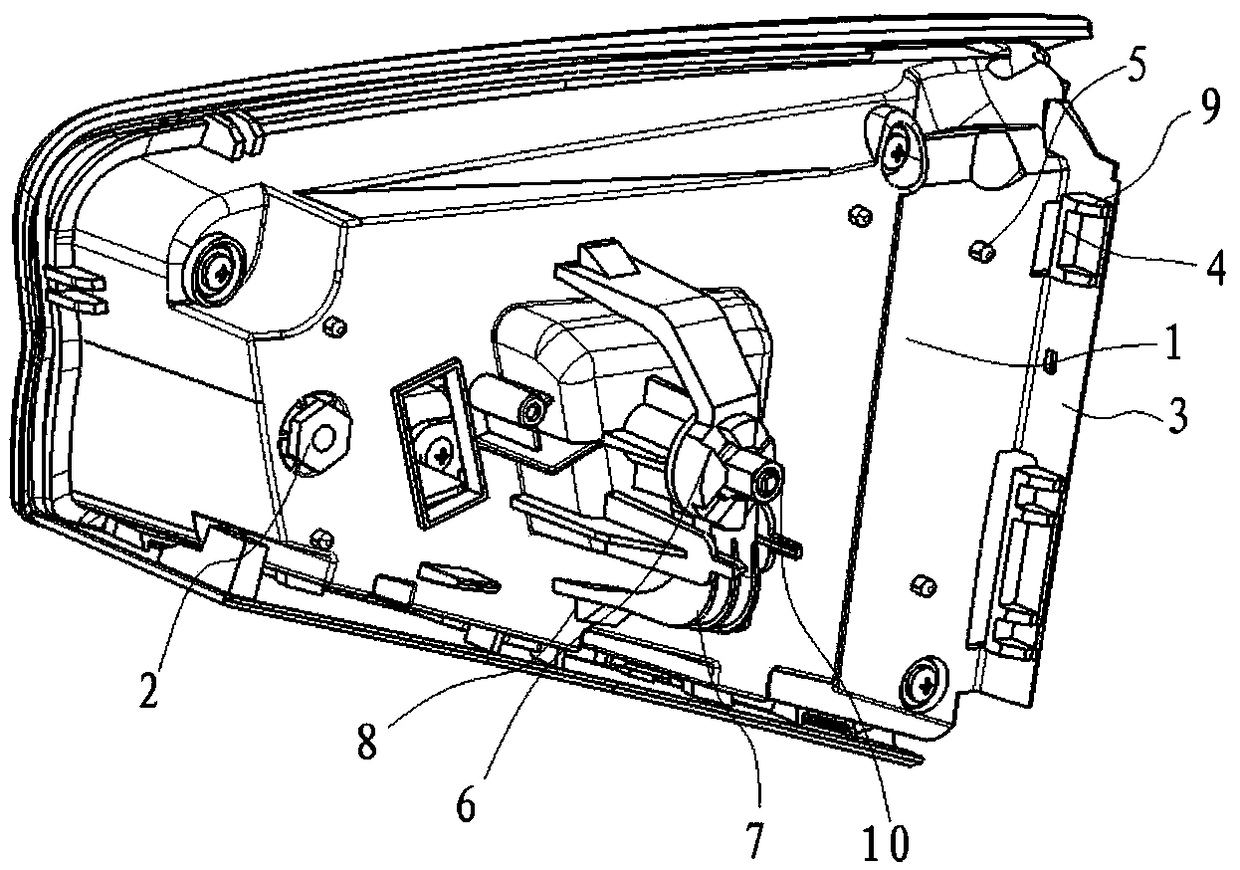

[0020] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

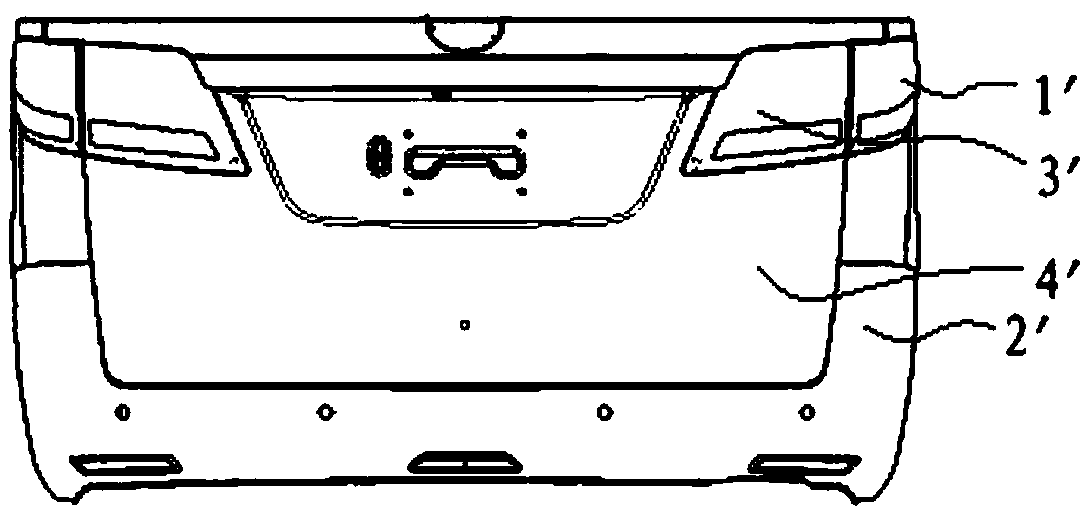

[0021] Such as image 3 As shown, the embodiment of the present invention provides a rear combination lamp installation and fixing structure, including a lamp body 1 and a first fixing assembly, a second fixing assembly and an embedded nut 2 arranged on the back of the lamp body 1. The first fixing component and the embedded nut 2 are arranged on both sides of the second fixing component, wherein:

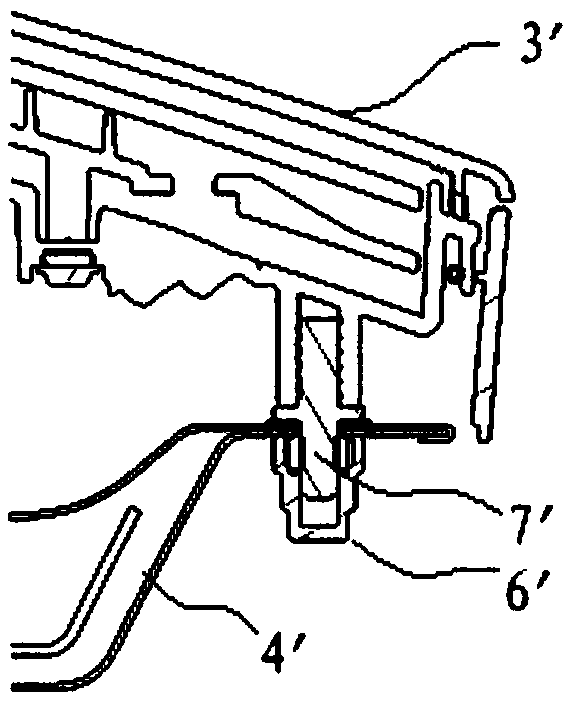

[0022] By setting embedded nuts 2 on the lamp body 1, the bolts are driven into the embedded nuts 2 to fix the lamp body 1 on the trunk lid sheet metal 11, as Figure 6 As shown, the pre-embedded nut 2 is threadedly matched with the lamp body 1, and the outside of the pre-embedded nut 2 is 3mm higher than the surface of the lamp body 1, so as to facilitate tightening or loosening of the pre-embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com