Apparatus for screen assembly

A screen and bracket technology, applied in the field of electronic terminals, can solve the problems of high possibility, slow touch screen assembly, glue overflow and uneven gap, and achieve the effect of preventing glue overflow and uneven gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described by means of embodiments below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the following embodiments.

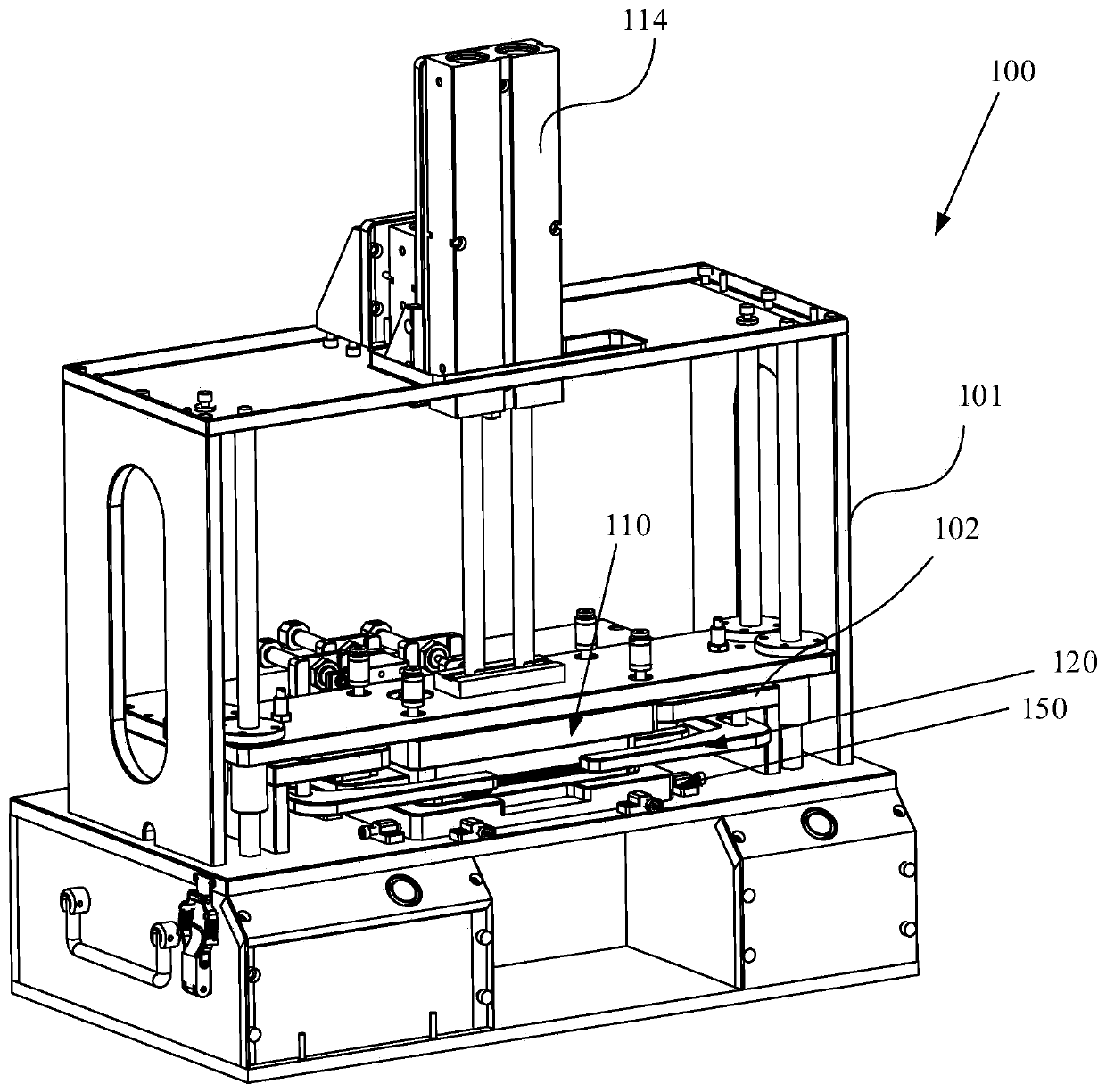

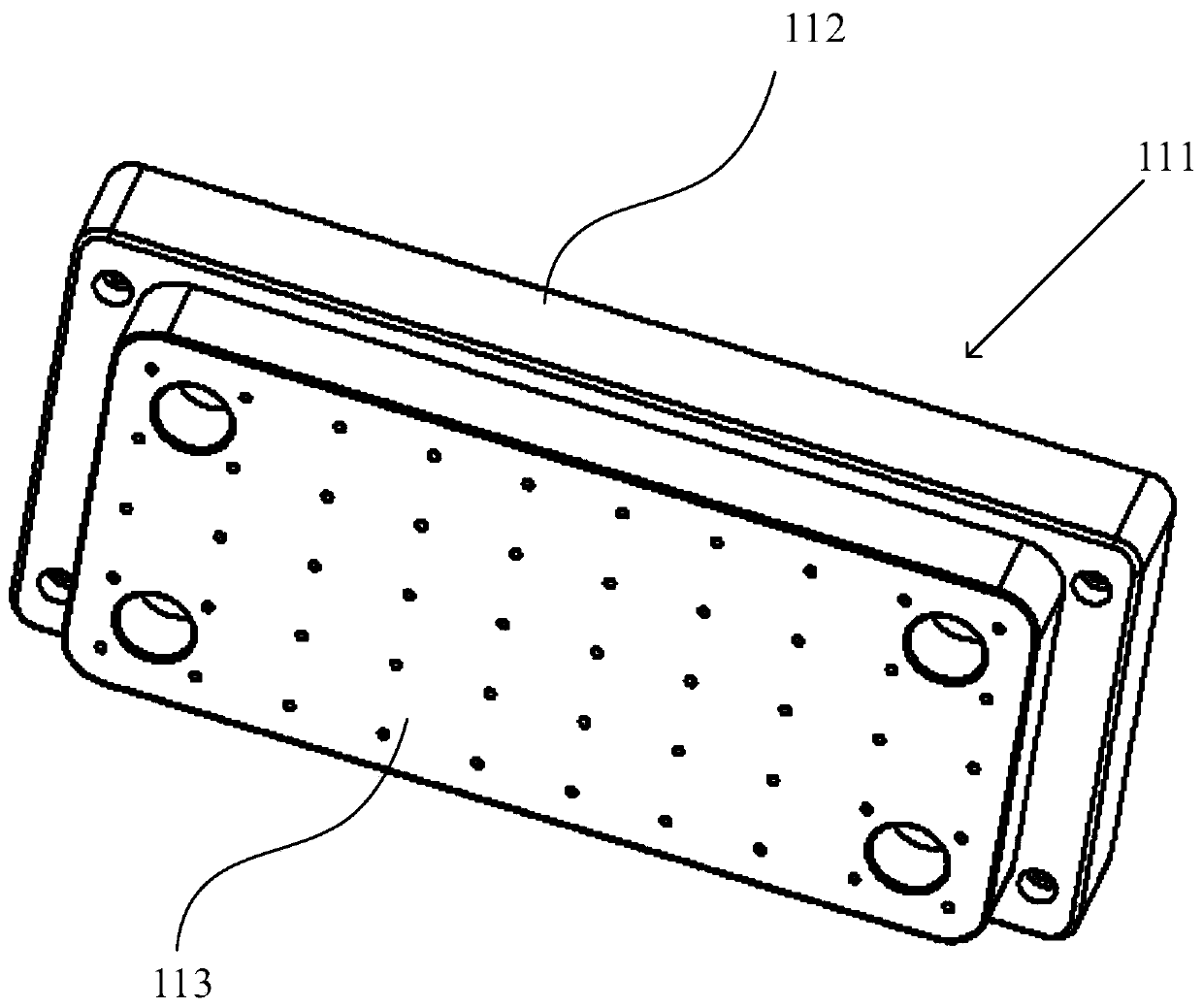

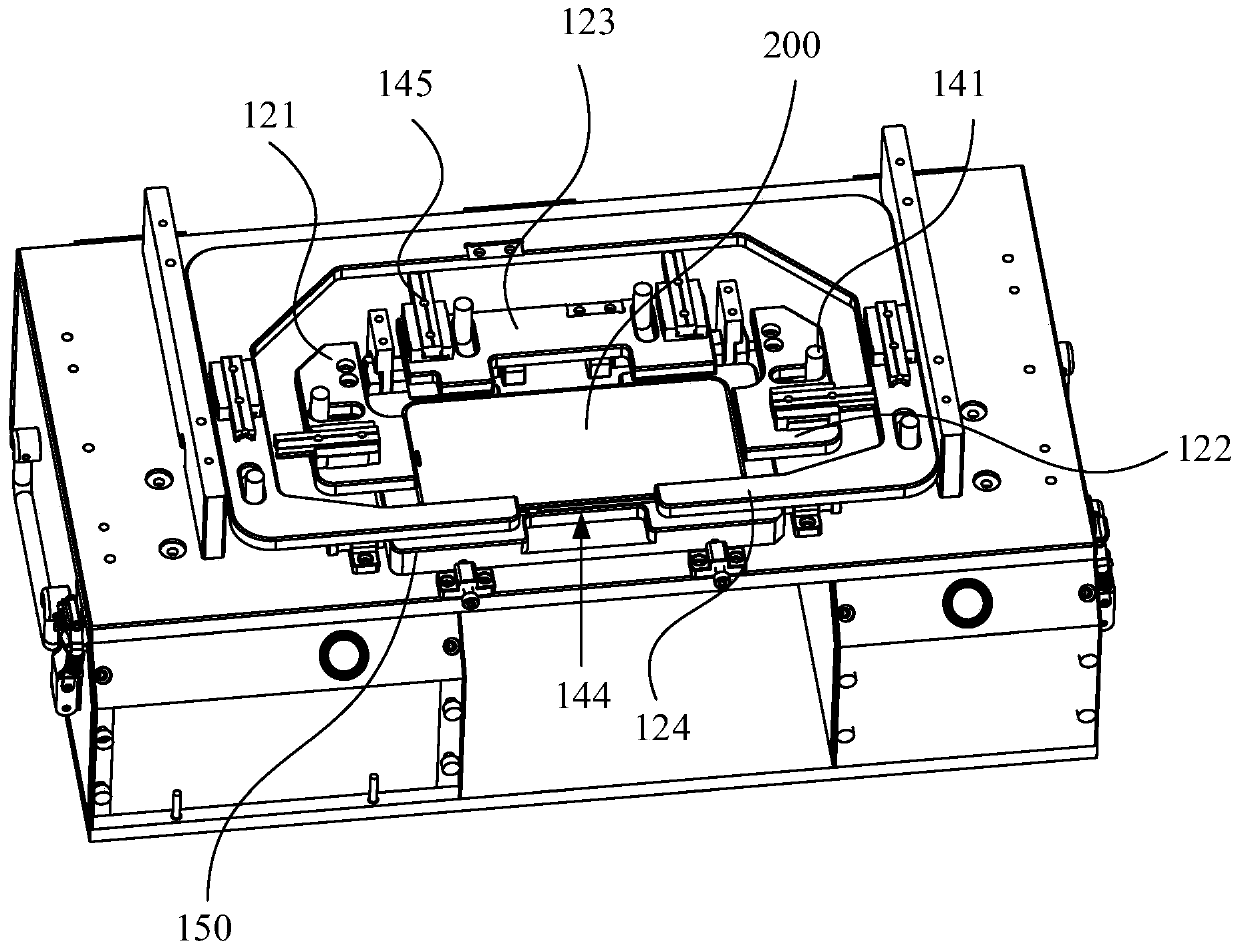

[0059] Such as figure 1 As shown, the device 100 is used to paste the screen 200 on the casing.

[0060] The device 100 may be suitable for assembling terminal equipment including a mobile phone, a tablet computer, a PDA (Personal Digital Assistant, personal digital assistant), a POS (Point of Sales, sales terminal), a vehicle-mounted computer, and the like. In this embodiment, a mobile phone screen is taken as an example.

[0061] The screen 200 may be a capacitive screen, a resistive screen, etc., and may be in the form of an LCD (Liquid Crystal Display, liquid crystal display), an OLED (Organic Light-Emitting Diode, organic light-emitting diode), or the like. The casing is the casing of the above-mentioned terminal device.

[0062] The device 100 includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com