Rear-row seat mounting bracket, rear floor assembly and mounting method of rear floor assembly

A technology for installing brackets and rear seats, which is applied in the field of vehicles, can solve the problems of low accuracy of installation points and uneven gaps, and achieve the effects of improving installation accuracy, avoiding uneven gaps, and reducing positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

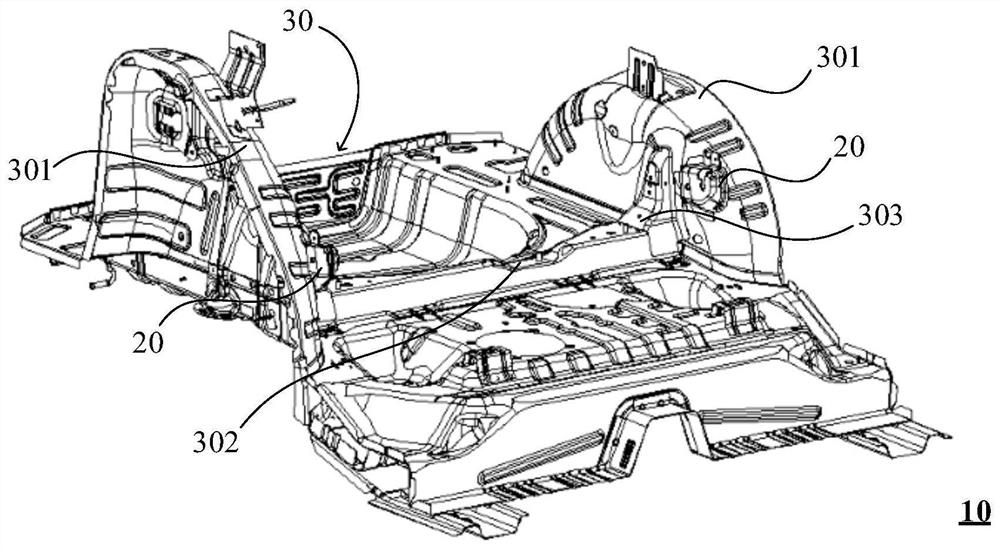

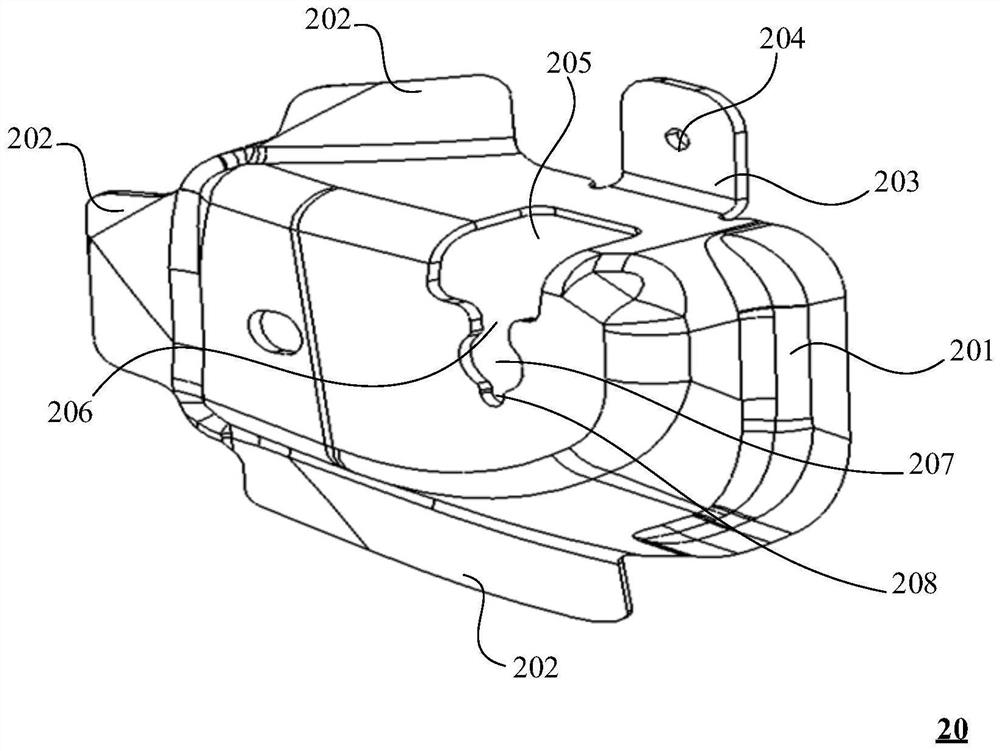

[0055] This embodiment discloses a method for installing the rear floor assembly 10, such as figure 2 As shown, the rear floor assembly 10 includes a rear floor subassembly 30 and a rear seat mounting bracket 20 , and the rear floor subassembly 30 includes a rear wheelhouse inner panel 301 . Such as figure 1 As shown, the installation method includes the following steps:

[0056] Step 100, post-manufacturing floor subassembly 30;

[0057] Step 200 , welding the rear seat mounting bracket 20 to the inner panel 301 of the rear wheel house.

[0058]In this embodiment, after the rear floor subassembly 30 is manufactured, the rear seat mounting bracket 20 is installed on the rear wheel house inner panel 301 by welding. Reducing the accumulation of positioning errors can reduce the influence of positioning errors of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com