Electric steaming tank and water supplementing control method

A control method and electric steamer technology, applied in the field of electric steamer, can solve problems such as unmatched supply and demand of steam volume, influence on the taste of cooked food, residual condensed water, etc. Adjusting the effect of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

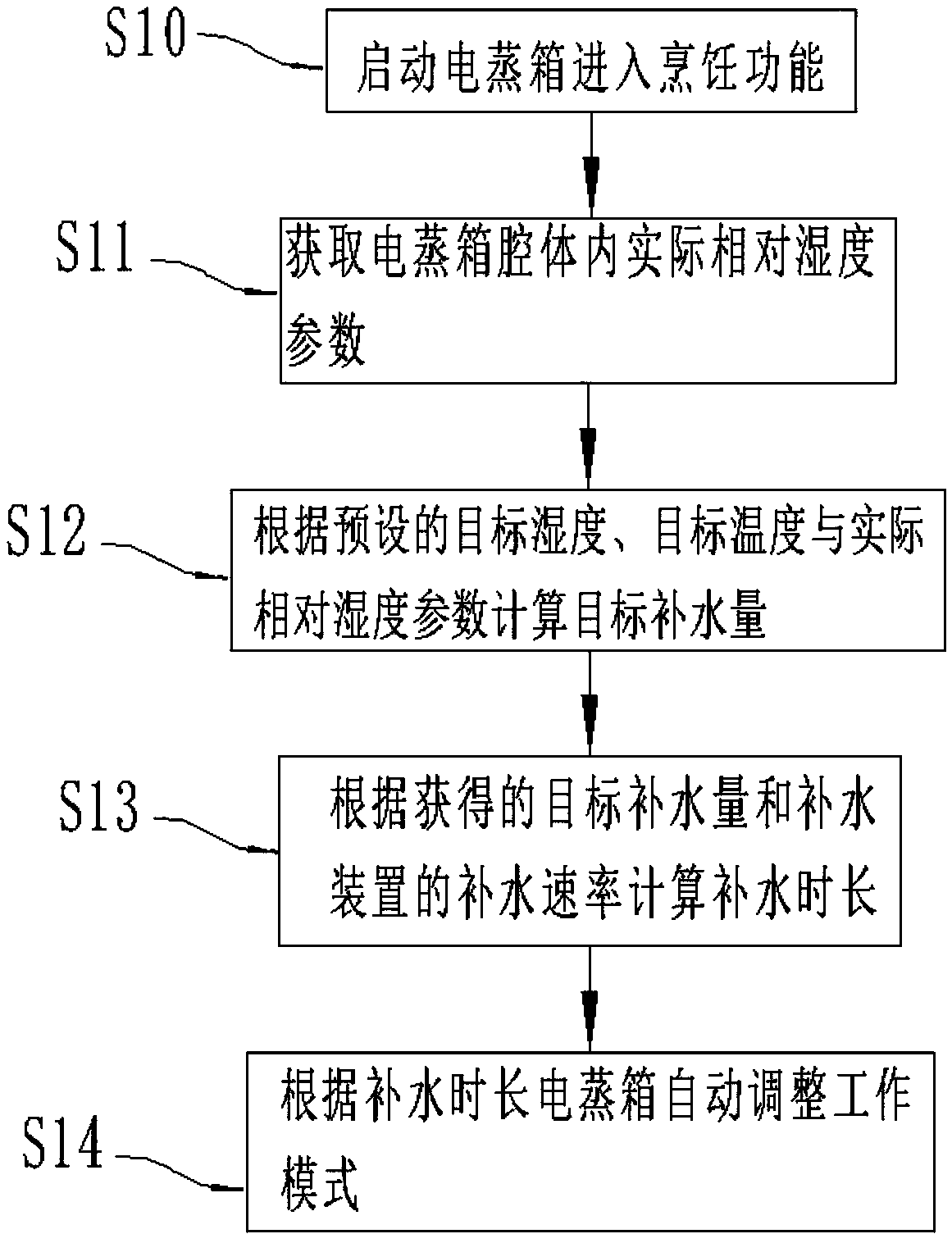

[0030] Embodiment one: if figure 1 As shown, this embodiment is a water replenishment control method for an electric steamer, including:

[0031] S10, start the electric steamer to enter the cooking function.

[0032] S11, acquiring the actual relative humidity h parameter in the cavity of the electric steamer.

[0033] S12, according to the preset target humidity H 0 , target temperature T 0 Calculate the target water replenishment amount W with the actual relative humidity parameter h, specifically, the target humidity H 0 , target temperature T 0 It can be preset by the user through the control device or can be set by the user according to actual needs during use. In this embodiment, according to the preset target humidity H 0 , target temperature T 0 Calculate the target water replenishment amount W with the actual relative humidity h parameter as follows: according to the preset target humidity H 0 The difference △H with the actual relative humidity h and the targ...

Embodiment 2

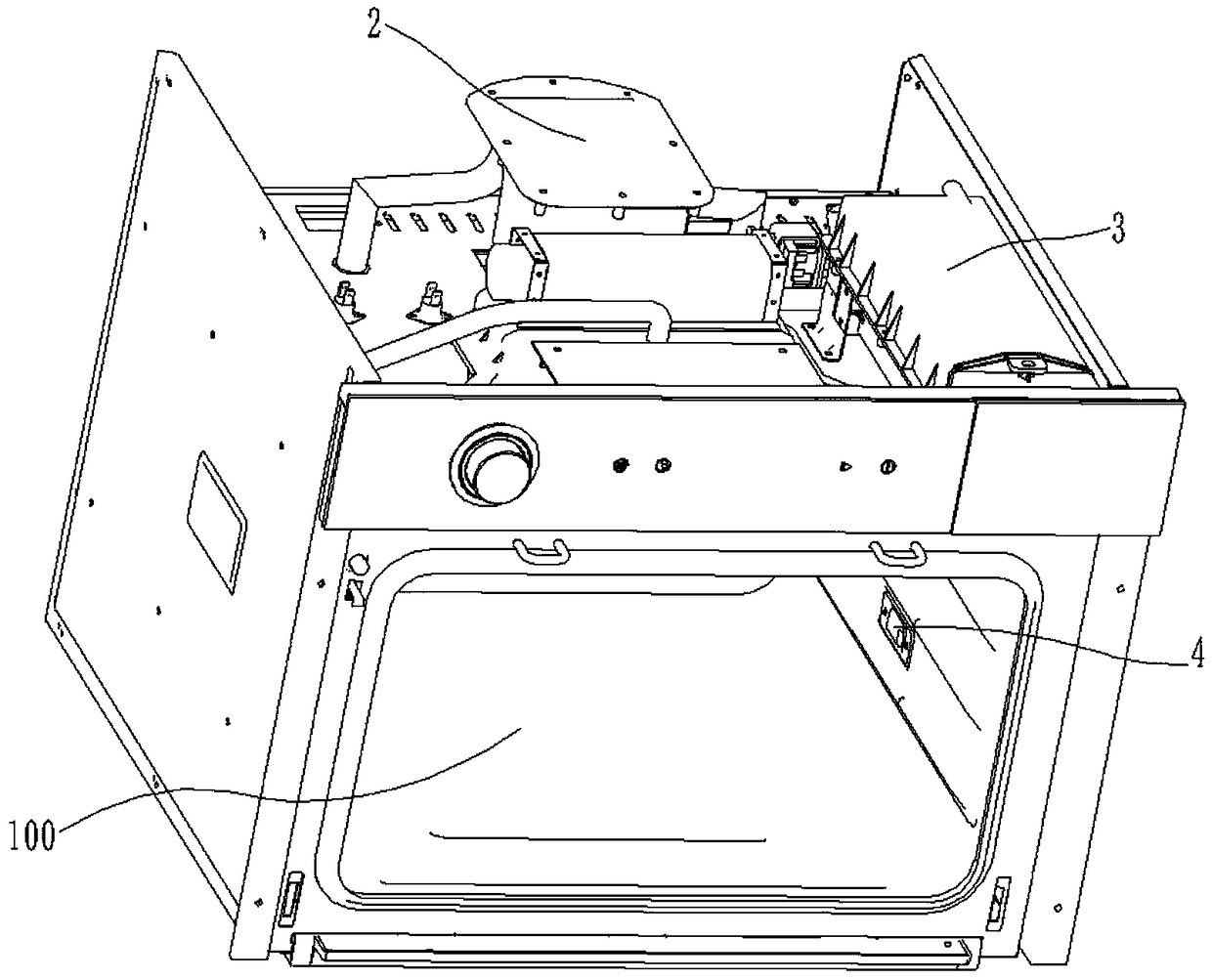

[0050] Embodiment two, such as figure 1 and figure 2 As shown, the present embodiment is an electric steamer, and the electric steamer has a cavity 100, a steam generating device 2, a water replenishing device 3 and a water pump, wherein the water replenishing device 3 is connected to the steam generating device 2, and the water replenishing device 3 is a steam generator. The device 2 provides replenishing water, the steam generating device 2 is connected to the cavity 100, the steam generating device 2 works to generate steam and provides high-temperature steam for the cavity 100 to cook food, the water pump is arranged between the water replenishing device 3 and the steam generating device 2, the control device and the water pump The water replenishment rate of the water replenishment device is adjusted by controlling the water pump. It has a simple structure and reliable operation, and can conveniently realize the purpose of adjusting the water replenishment rate of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com