A production process of degradable polyester knitted weft-knitted fabric

A production process and polyester technology, applied in the field of production process of degradable polyester knitted weft knitted fabrics, can solve the problems of poor performance and degradation effect of degradable fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

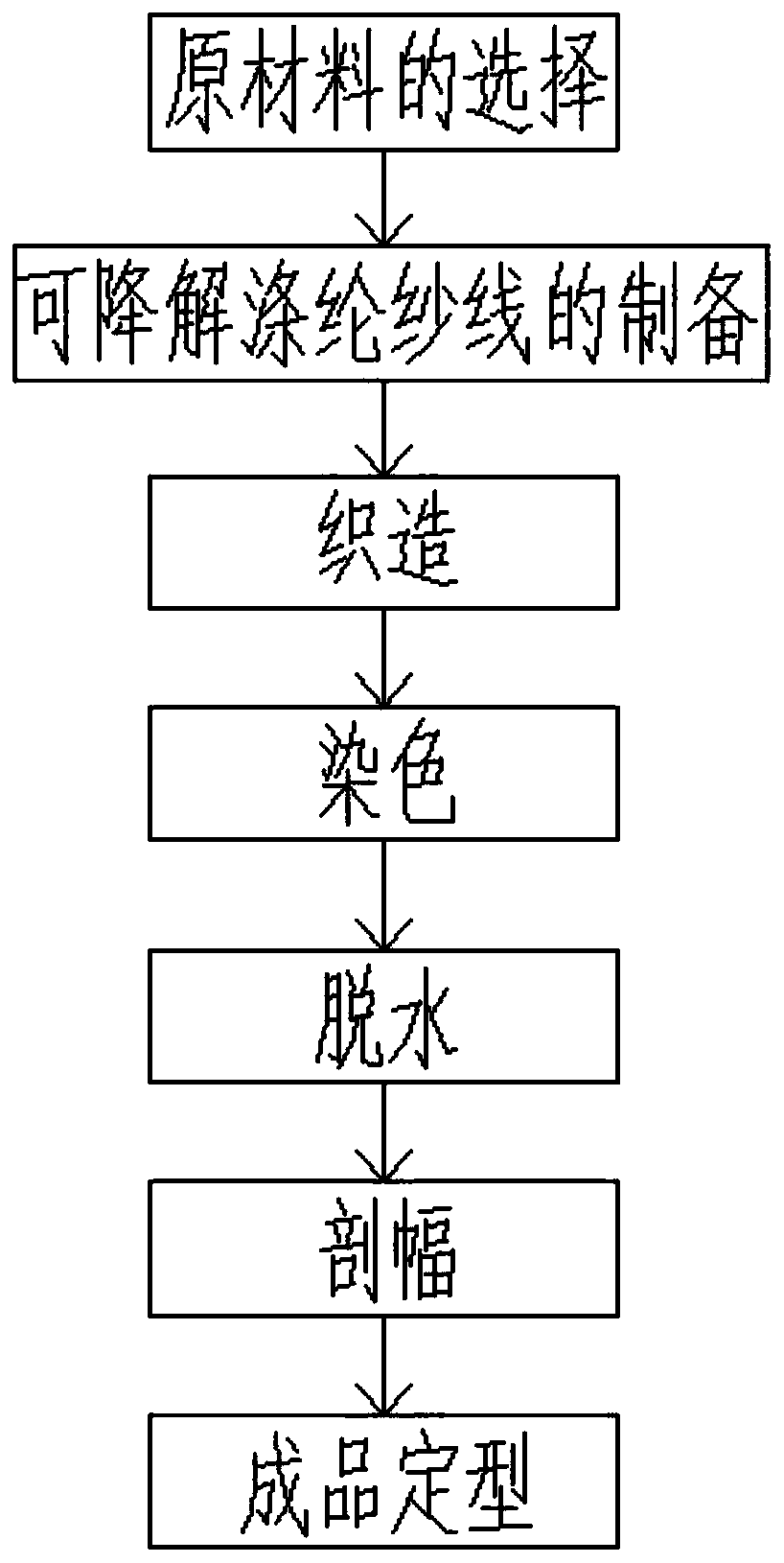

[0017] A production process of degradable polyester knitted weft-knitted fabrics. After the selection of raw materials, preparation of degradable polyester yarns, weaving, dyeing, dehydration, width cutting and final product setting steps, the production process of degradable polyester knitted weft-knitted fabrics is completed. ;Specific steps are as follows:

[0018] (1) Selection of raw materials: polyester and degradable additives, the mass ratio of degradable additives to polyester is 1:99;

[0019] (2) Preparation of degradable polyester yarn: mix polyester and degradable auxiliary agent according to the above mass ratio, and prepare degradable polyester yarn through melt spinning method; BioSphere Plastic 201 is selected as biodegradable auxiliary agent, It is a biosphere plastic with degradable effect.

[0020] (3) Weaving: The prepared degradable polyester yarn is woven with a special structure to obtain a knitted weft-knitted fabric; the special structure is a double...

Embodiment 2

[0026] A production process of degradable polyester knitted weft-knitted fabrics. After the selection of raw materials, preparation of degradable polyester yarns, weaving, dyeing, dehydration, width cutting and final product setting steps, the production process of degradable polyester knitted weft-knitted fabrics is completed. ;Specific steps are as follows:

[0027] (1) Selection of raw materials: polyester and degradable additives, the mass ratio of degradable additives to polyester is 1:99;

[0028] (2) Preparation of degradable polyester yarn: mix polyester and degradable auxiliary agent according to the above mass ratio, and prepare degradable polyester yarn through melt spinning method; BioSphere Plastic 201 is selected as biodegradable auxiliary agent, It is a biosphere plastic with degradable effect.

[0029] (3) Weaving: The prepared degradable polyester yarn is woven with a special structure to obtain a knitted weft-knitted fabric; the special structure is a double...

Embodiment 3

[0035] A production process of degradable polyester knitted weft-knitted fabrics. After the selection of raw materials, preparation of degradable polyester yarns, weaving, dyeing, dehydration, width cutting and final product setting steps, the production process of degradable polyester knitted weft-knitted fabrics is completed. ;Specific steps are as follows:

[0036] (1) Selection of raw materials: polyester and degradable additives, the mass ratio of degradable additives to polyester is 1:99;

[0037] (2) Preparation of degradable polyester yarn: mix polyester and degradable auxiliary agent according to the above mass ratio, and prepare degradable polyester yarn through melt spinning method; BioSphere Plastic 201 is selected as biodegradable auxiliary agent, It is a biosphere plastic with degradable effect.

[0038] (3) Weaving: The prepared degradable polyester yarn is woven with a special structure to obtain a knitted weft-knitted fabric; the special structure is a double...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap