Detection system for trolley of tailing thickener

A thickener and trolley technology, applied in chemical instruments and methods, separation methods, precipitation separation, etc., can solve problems such as mineral processing accidents, tailings accumulation, transportation, etc., and achieve the effect of reducing fault judgment time and preventing production accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

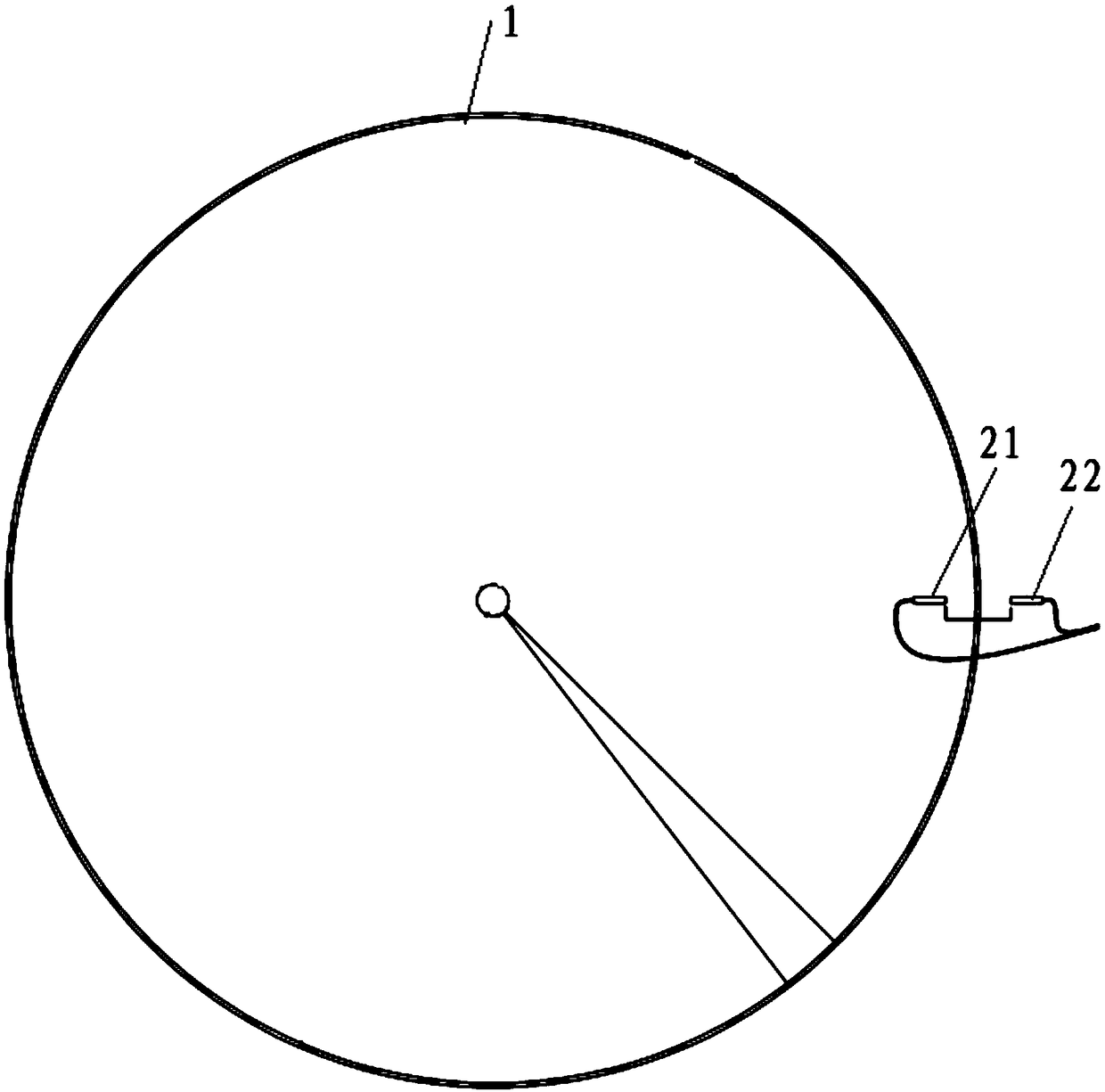

[0025] The embodiment of the present invention provides a tailings thickener trolley detection system, please refer to figure 1 , the system includes:

[0026] Thickener center plate;

[0027] A code disc 1, the code disc 1 is arranged on the central disc of the thickener, and the code disc 1 and the central disc of the thickener have the same central axis;

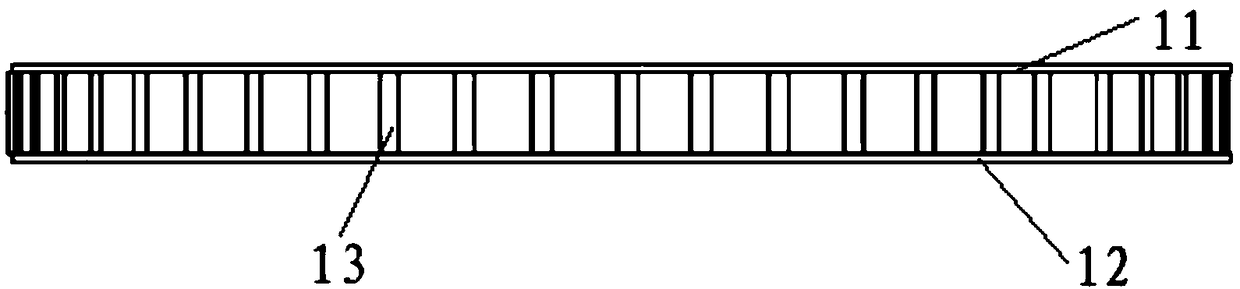

[0028] Further, the code wheel 1 also includes: a first ring 11; a second ring 12, the second ring 12 is set correspondingly to the first ring 11, and the second ring 12 and There is a first distance between the first rings 11; N pillars 13, the N pillars 13 are evenly arranged between the second ring 12 and the first ring 11, and the N Each pillar 13 has a first height.

[0029] Further, the code wheel 1 further includes: N is a positive integer, and N is 48.

[0030] Further, the code wheel 1 further includes: the first distance is 200mm, and the first height is 200mm.

[0031] Further, the code wheel 1 also includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com