Square button embossing method

A button and embossing technology, applied in decorative art, embossed decorations, etc., can solve the problems of difficult processing of complex patterns and high mold production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

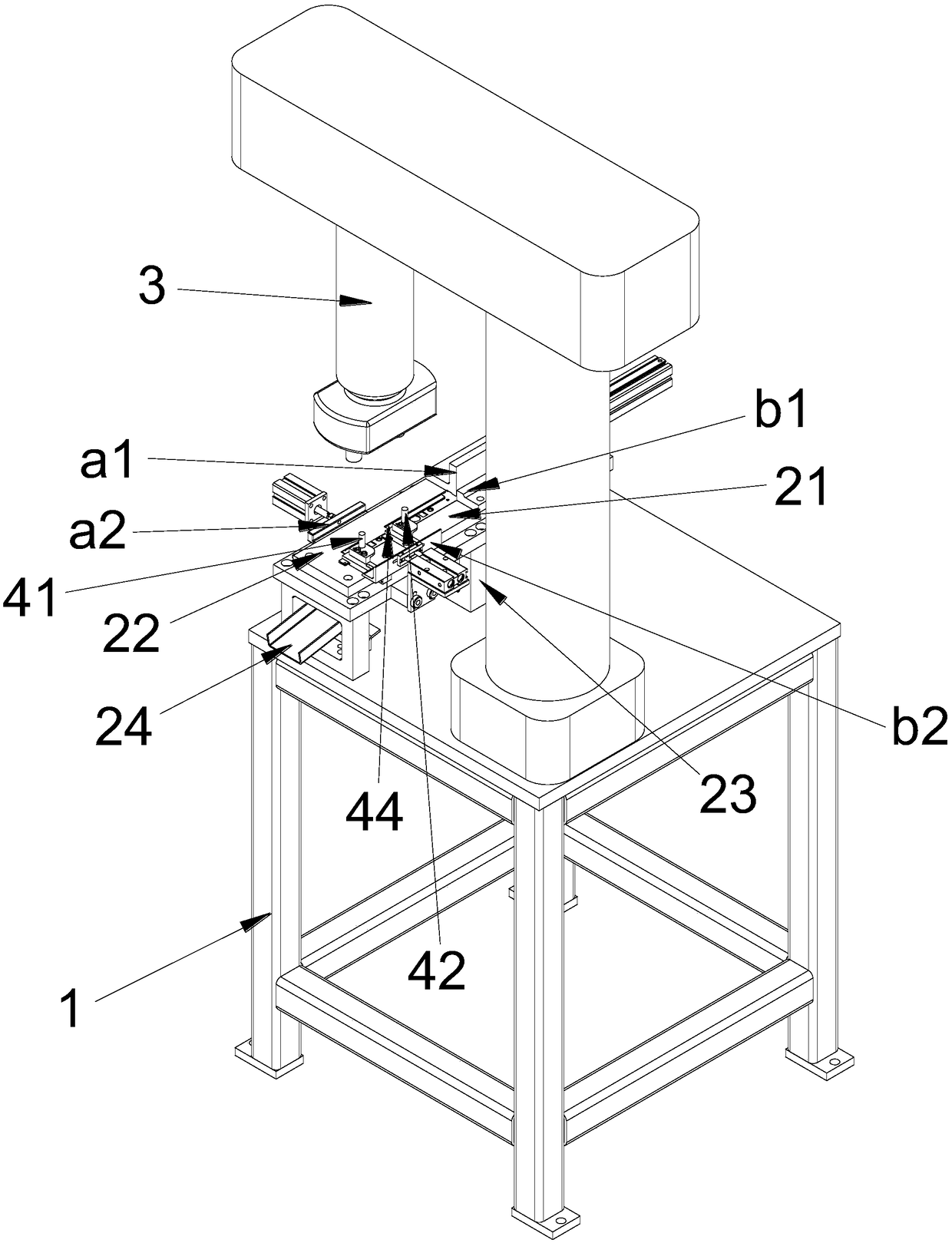

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the above technical solutions will be further elaborated below in conjunction with the accompanying drawings.

[0021] A button embossing equipment as shown in the figure, including frame 1, x-axis slide rail 21, fixed block 22, gantry frame 23, push block a1, push block b1, discharge frame 24, clamp a2, clamp b2 , Press down mechanism 3, sensing rod 41, sensing switch 42, position sensor 44, position sensing plate 5. It should be noted that the pressing mold of the button is not drawn, so the opening at the fixing block is not shown in the drawings.

[0022] Mainly comprise the steps during the concrete work of the present invention:

[0023] The first step is loading. The operator installs the relevant button molds on the fixtures a2 and b2, and the steering column of the pressing mechanism 3 pulls the pneumatic manipulator to rotate and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com