Embossing-type new year picture making machine

A production machine and embossing technology, which is applied in the field of embossed New Year picture making machines, can solve the problems of time-consuming engraving, dependence, difficulty and complexity of engraving work, etc., and achieve the effect of clear and smooth embossing texture and guaranteed working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

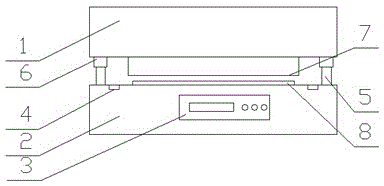

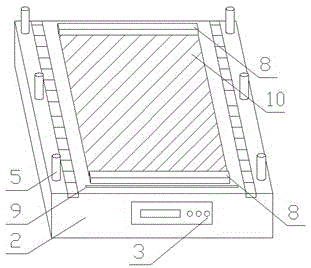

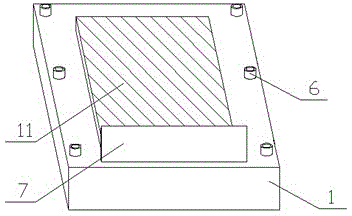

[0011] An embossed New Year picture making machine, characterized in that it includes an upper mold base 1, a lower mold base 2, a controller 3, a guide rail 4, a guide post 5, a guide sleeve 6, a cutting knife 7, a spring pad 8, and a cutting opening 9 , concave formwork 10, convex formwork 11, convex formwork 11 is installed on the upper die base 1, cutting knife 9 is installed on one side of the convex formwork 11, guide sleeve 6 is installed around the convex formwork 11, the lower die base 2 is connected below the upper die base 1, and Die plate 10 is installed on the mold base 2, guide pillars 5 are installed around the die plate 10, a cutout 9 is provided on one side of the die plate 10, spring pads 8 are installed on both sides of the die plate 10, guide rails 7 are installed on both sides of the spring pad 8, and the lower mold base 2 Install the controller 3 on one side.

Embodiment 2

[0013] The staff puts the wooden board on the guide rail 4, and the guide rail 4 transfers the wooden board to the convex template 11 and the concave template 10, and then the upper mold base 1 moves downward for mold clamping and embossing. After the imprinting is completed, the upper mold base 1 moves upward to open the mold , the guide rail will move the embossed plank outwards, move out the lower mold base 2 and close the mold again to emboss the next plank, and the cutting knife 7 will cut the embossed plank at the same time, so that the embossed plank has the same size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com