Full-automatic nuclear phase device of universal switch cabinet and using method thereof

A switchgear, fully automatic technology, applied in the direction of switchgear, measuring devices, motor vehicles, etc., can solve the problems of unsafety and difficulty in phase verification of switchgear, and achieve the effect of simple process operation and guaranteed working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

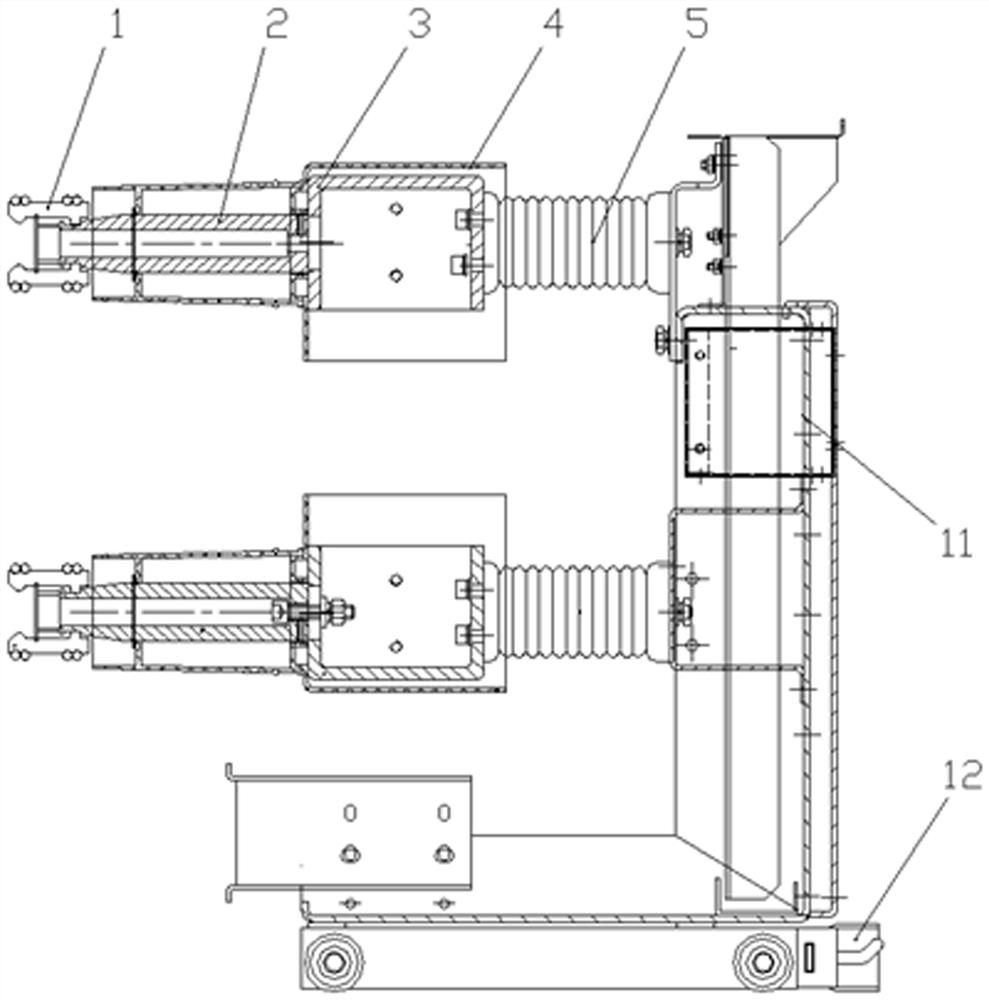

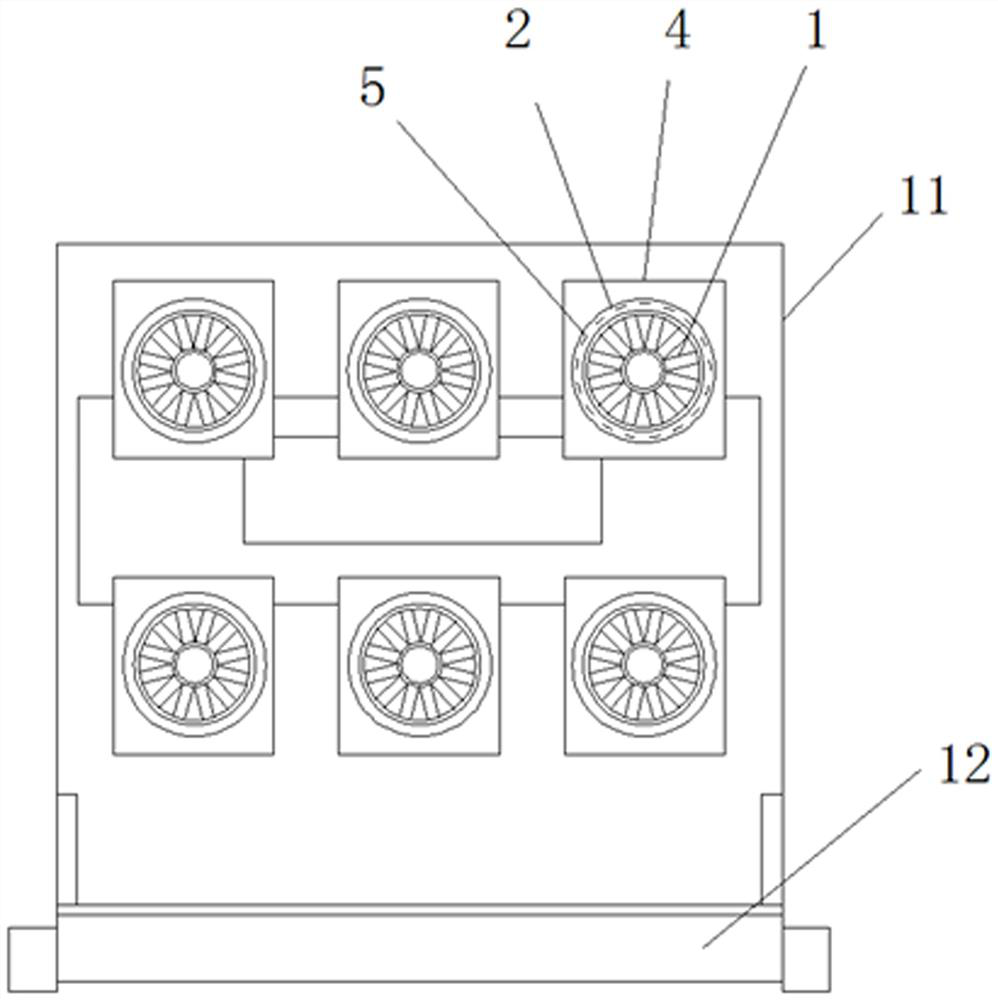

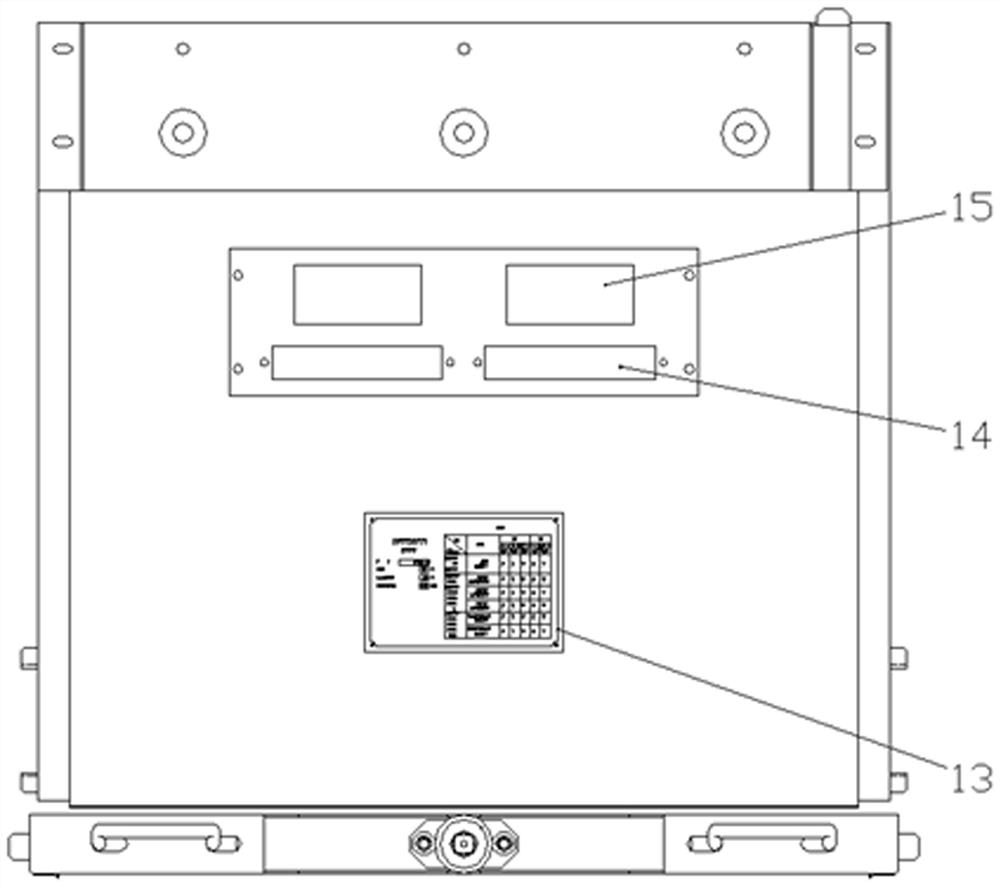

[0022] like Figure 1-4 As shown, a general-purpose switch cabinet automatic phase verification device includes a frame 11 whose size matches the switch cabinet and a chassis vehicle 12 installed at the bottom of the frame 11; the frame 11 is L-shaped, vertical placed, the frame 11 is respectively provided with three groups of detection arms corresponding to the upper and lower circuit joints in the switch cabinet, and each group of detection arms includes two detection arms arranged in parallel up and down; the detection arms include contact arms 2, Aluminum block 3 and sensor 5; the contact arm 2, aluminum block 3 and sensor 5 are connected sequentially from left to right, the right end of the sensor 5 is connected to the inner side of the opening of the frame 11, and the left end of the contact arm 2 is equipped with a moving contact 1; the moving contact 1, the contact arm 2, the aluminum block 3, and the sensor 5 are electrically connected in sequence; the outer side of t...

Embodiment 2

[0028] The difference from Embodiment 1 is that an insulating sheath 4 is installed on the outer side of the aluminum block 3 .

[0029] The working principle of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0031] The difference from Embodiment 2 is that a handle is installed on the right end of the chassis.

[0032] The working principle of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com