A high-precision aluminum alloy profile forming device

A technology of aluminum alloy profiles and forming devices, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc., can solve the problems of prone to scratches on the surface, waste of resources and time, and low accuracy errors of aluminum alloy profiles. Major problems, to achieve the effect of reducing physical strength and operational complexity, improving work efficiency, and reducing waste of resources

Active Publication Date: 2022-06-03

XUCHANG UNIV

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Stamping forming refers to the process of applying external force to plates, strips, pipes and profiles by presses and molds to cause plastic deformation or separation to obtain workpieces (stamping parts) of required shape and size. Therefore, processing The quality of the produced parts is stable, the consistency is good, and it has the characteristics of "exactly the same". The material utilization rate is high, the service life of the mold is long, and the production cost is low. The existing profile processing device is not stable enough to fix the profile during long-term continuous operation. , easy to loosen, and when some high-precision profiles are clamped and fixed, scratches are likely to occur on the surface, resulting in a large accuracy error after the aluminum alloy profile is formed, and then the scratches need to be repaired again, or even scrapped. Waste of resources and time, the profile cutting interface is not smooth, burrs often appear, and the cutting part will generate a lot of heat, causing burns to the operator's hands and other parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

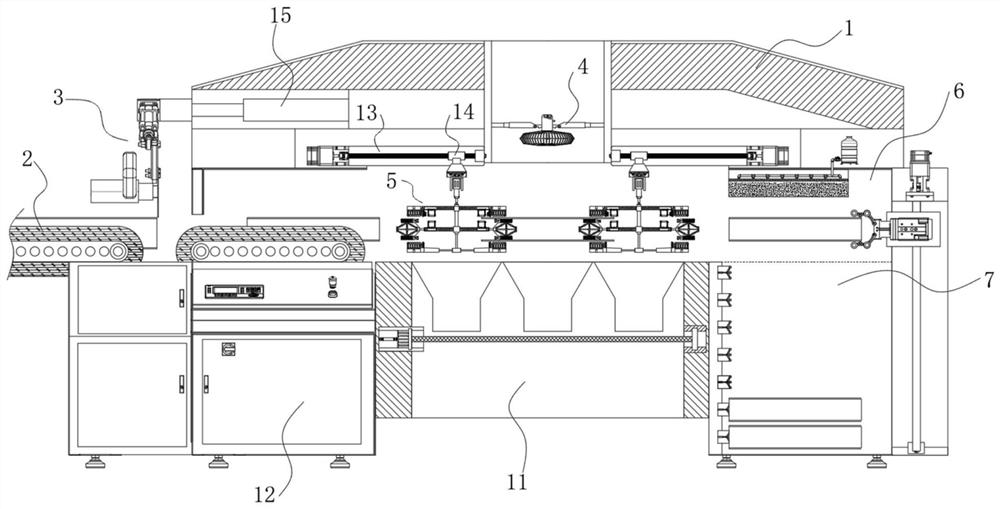

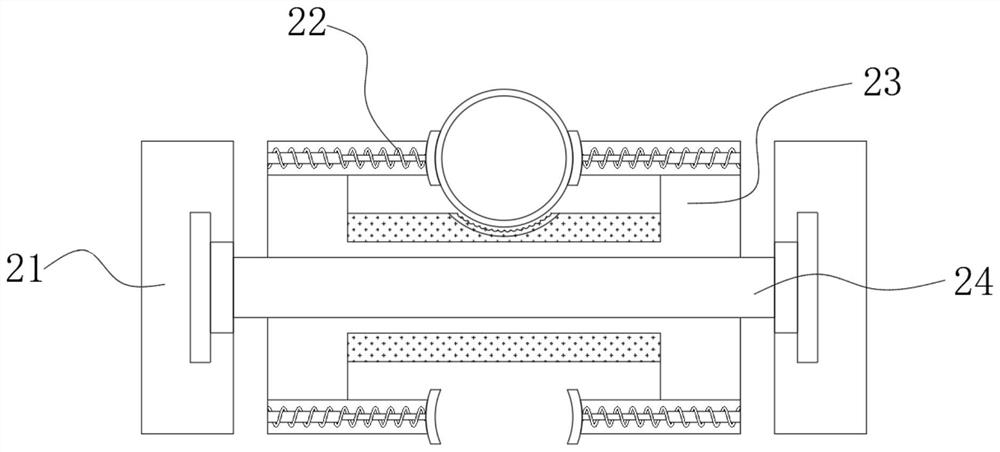

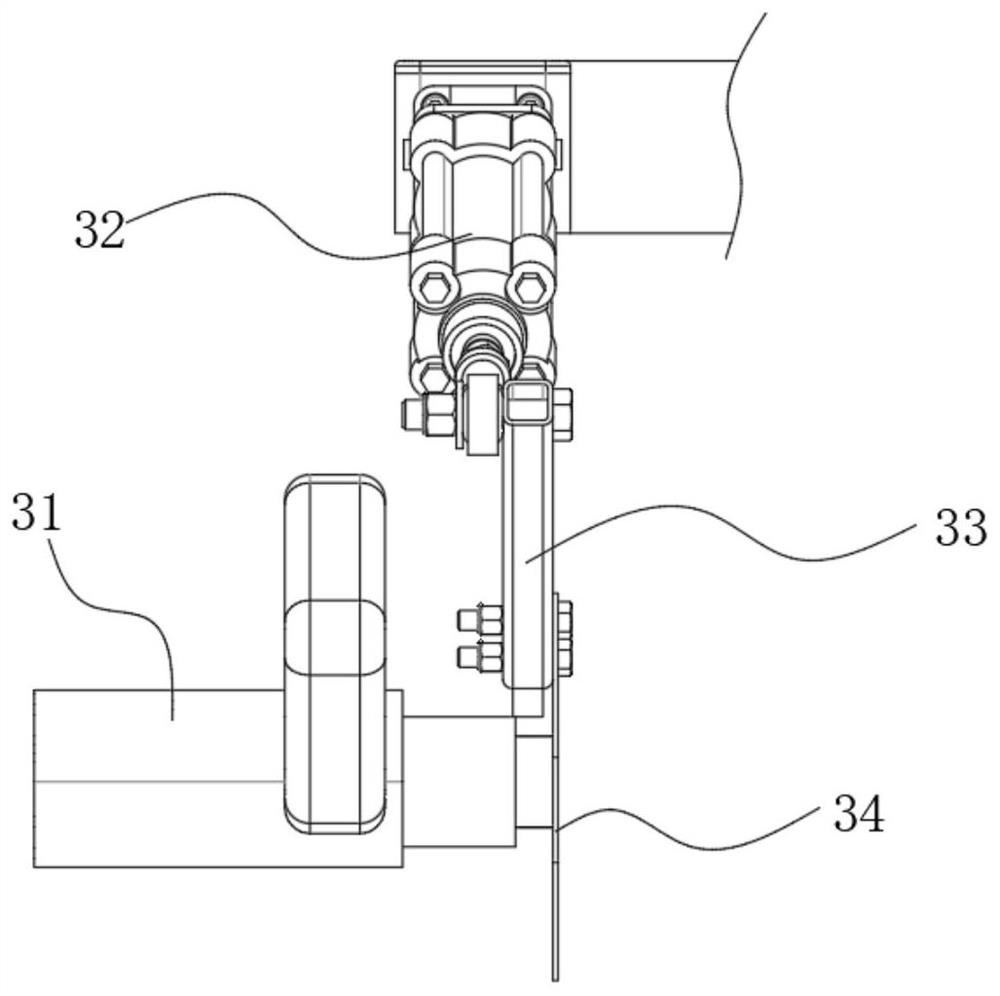

The invention discloses a high-precision aluminum alloy profile forming device, which includes a box shell, a feeding device, a cutting device and a grinding and cleaning device. A ventilation pipe is opened in the center of the upper end shell cover of the box casing, and the inside of the ventilation pipe is A ventilation fan is provided, and the inner bottom of the box shell is provided with a console, a recovery box, and a collection device in sequence from left to right, and a feeding device is installed in the space above the console, and is located above the feeding device A cutting device is also provided, and the displacement in the horizontal direction is adjusted by the telescopic machine three on the left side of the inside of the shell cover. A grinding and cleaning device connected to the bottom end of the shell cover is arranged above the recovery box. The ventilation pipes are arranged in two groups with axial symmetry, and the aluminum alloy profiles are polished, corner-cut and cleaned.

Description

A high-precision aluminum alloy profile forming device technical field [0001] The present invention relates to the technical field of metal processing, in particular to a high-precision aluminum alloy profile forming device. Background technique Aluminum alloy material has good casting properties and plastic workability, good electrical and thermal conductivity, good Corrosion resistance and weldability, can be used as a structural material. Stamping refers to the forming of sheets, strips, pipes and Profiles, etc. apply external force to plastically deform or separate, so as to obtain the workpiece (stamping) of the required shape and size. The processing and forming method, so the quality of the processed parts is stable, the consistency is good, and it has the characteristics of "exactly the same". The utilization rate is high, the service life of the mold is long, and the production cost is low. The existing profile processing device, when it operates continuous...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B08B3/02B08B13/00B24B9/00B24B9/04B24B41/04B24B41/06B24B47/12B24B47/20B24B47/22B24B55/03B24B55/06

CPCB08B3/02B08B13/00B24B9/007B24B9/04B24B41/04B24B41/067B24B47/12B24B47/20B24B47/22B24B55/03B24B55/06Y02P70/10

Inventor 路晓静赵正印

Owner XUCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com