Water curtain dust-removing welding device for electric component for wireless charging

A technology for removing dust from electrical components and water curtains. It is applied in the direction of electrical components, electrical components, and electrical components to assemble printed circuits. It can solve problems such as being easily inhaled by the human body, scrapped, respiratory tract infection, heavy metal poisoning, etc., to avoid employee health and security. Work environment, the effect of improving the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

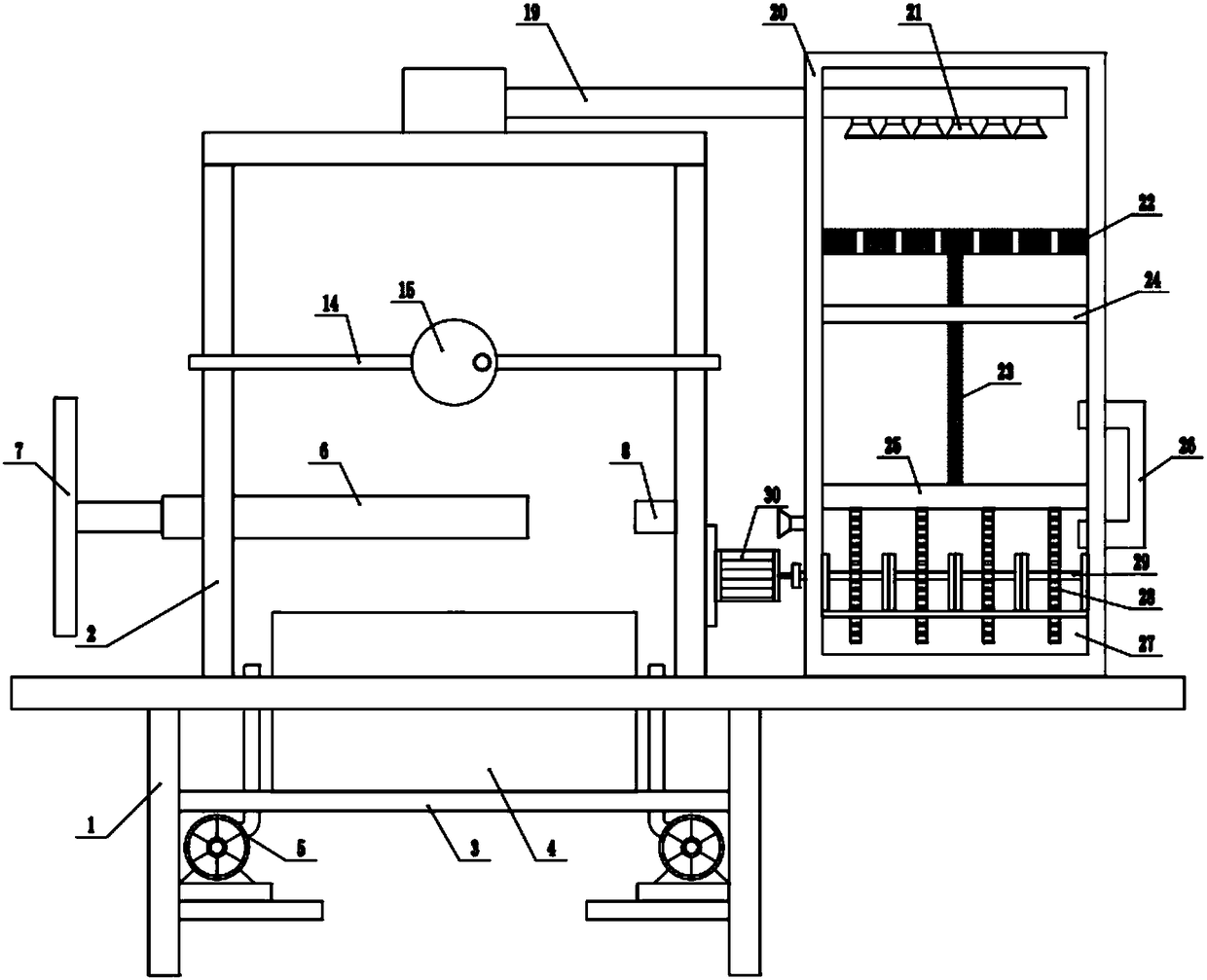

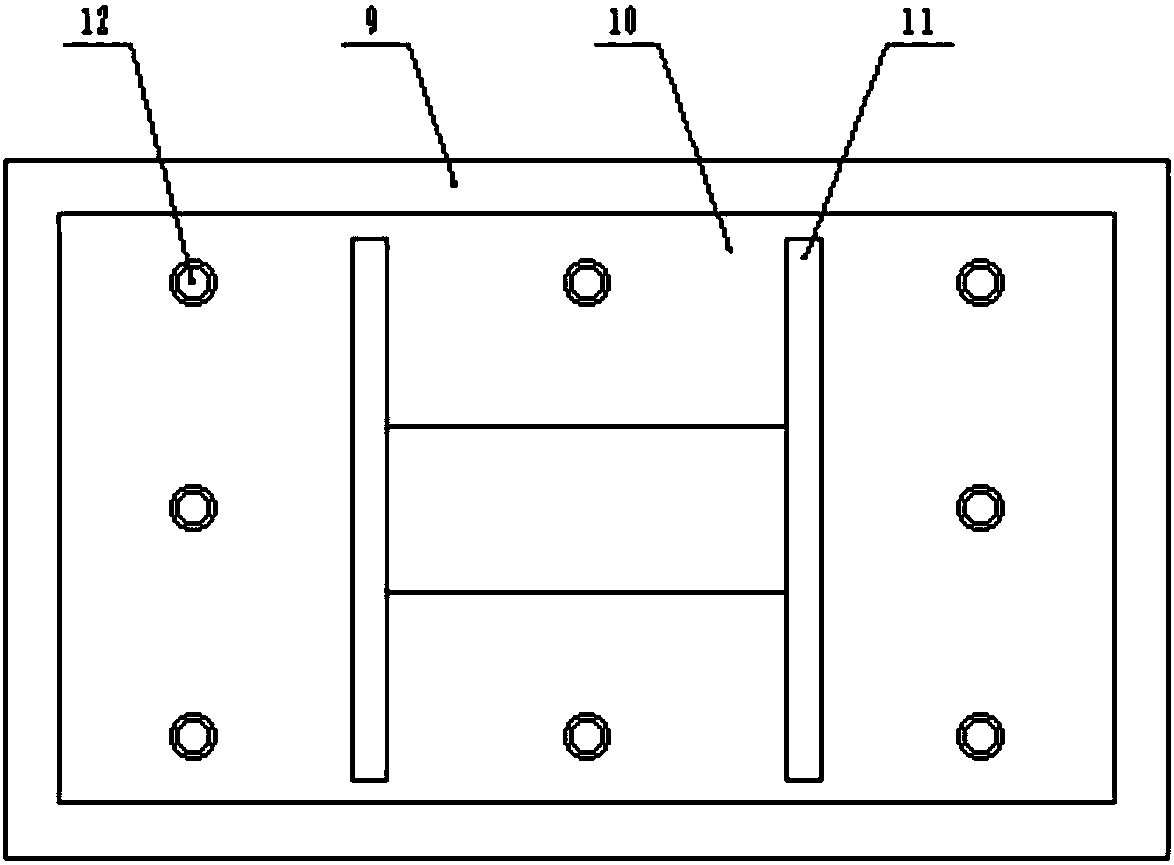

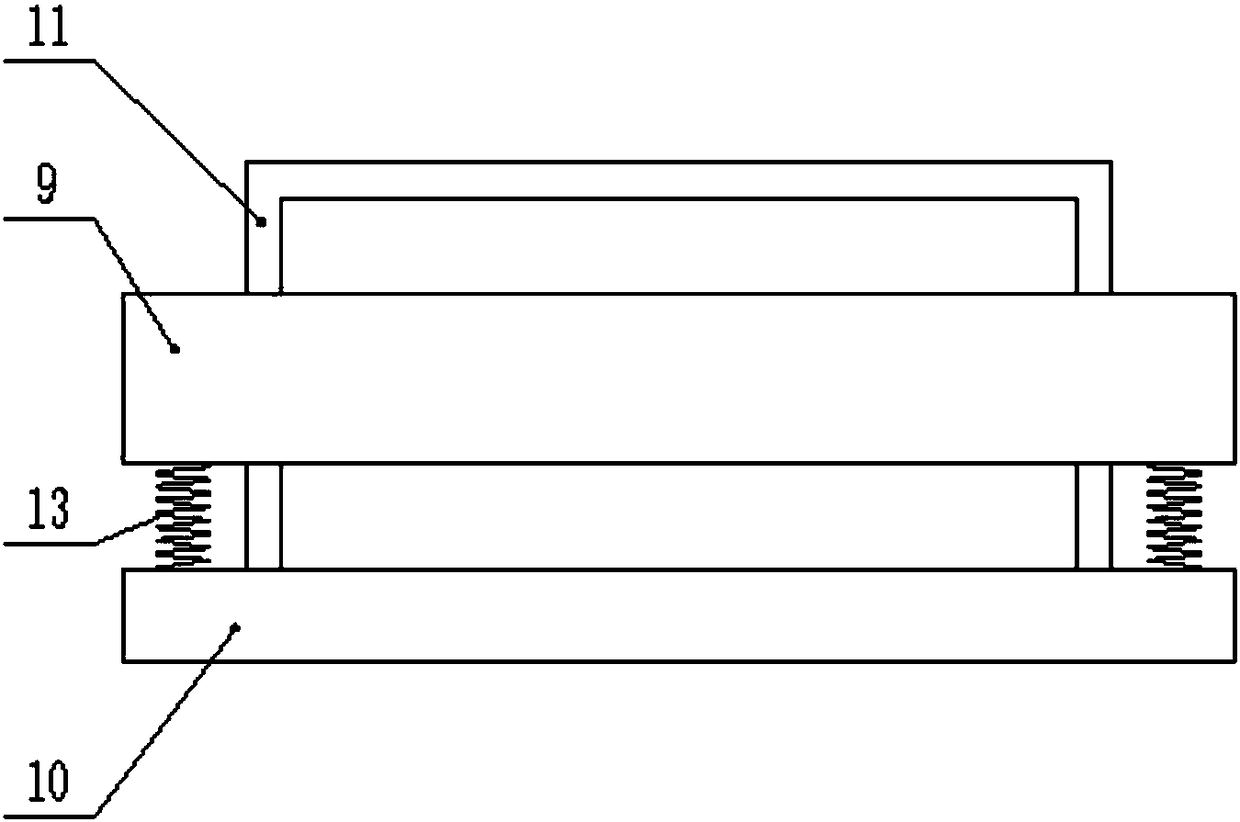

[0025] see Figure 1-4 , a wireless charging electric component water curtain dust removal type welding device, including a device body, the device body is provided with a support frame 1, a welding chamber 2 is provided above the support frame 1, and the connection between the welding chamber 2 and the support frame 1 The bottom of the welding chamber 2 is provided with an accommodating cavity 3, and the accommodating cavity 3 and the support frame 1 are fixedly connected by screws, and the interior of the welding chamber 2 communicates with the interior of the accommodating cavity 3. A soldering furnace 4 is set in the accommodation cavity 2, and a fan 5 is set on the device body, and the fan 5 is fixedly connected to the support frame 1 through the action of the bracket, and a circuit board mounting plate 6 is set inside the soldering chamber 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com