A kind of plant fiber flame retardant adhesive and preparation method thereof

A plant fiber and adhesive technology, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, starch adhesives, etc., can solve the impact, poor fire performance, difficult to achieve fire performance, safety performance and decorative effects, etc., to achieve the effects of enhancing compression resistance, long-lasting fire resistance, improving weather resistance and coloring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

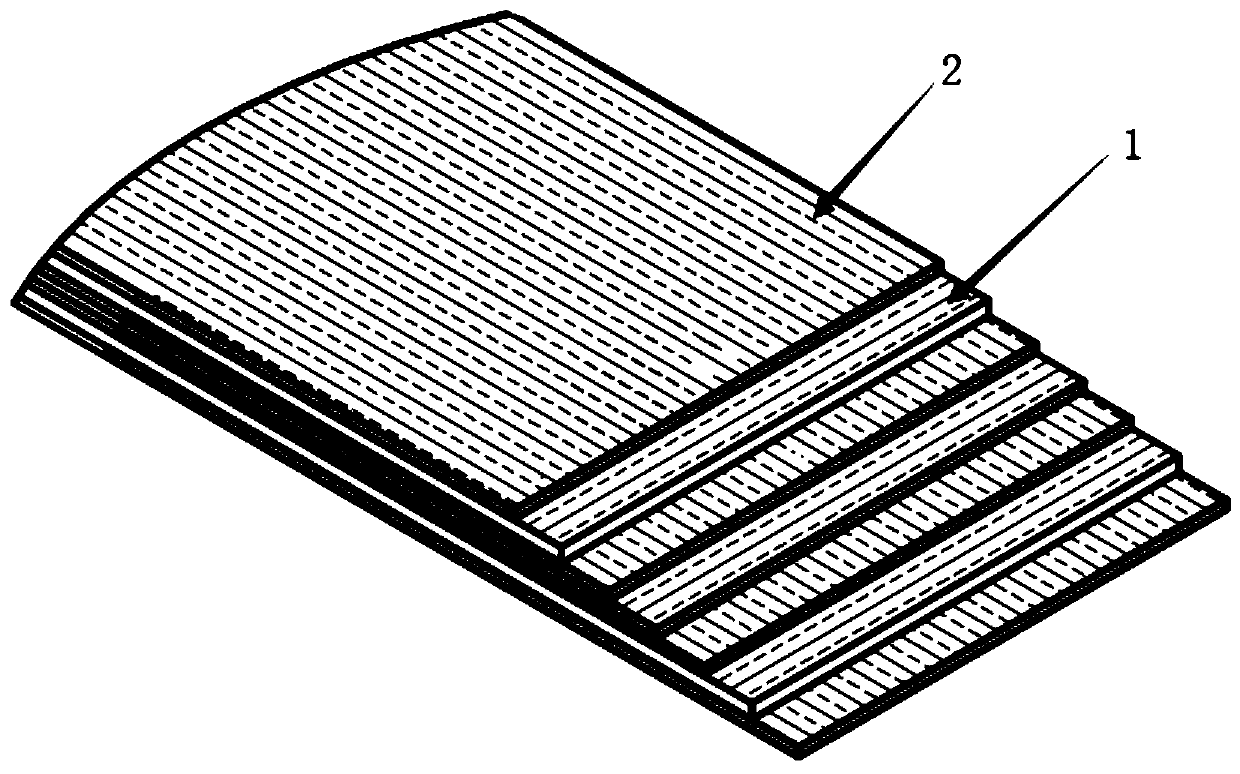

Image

Examples

Embodiment 1

[0021] A new flame-retardant adhesive for plant fibers, comprising the following components: 4g of trisodium phosphate, 50g of magnesium sulfate solution, 2g of calcium hydroxide, 3g of emulsifier, 60g of starch glue, 25g of phenolic resin, 3g of tartaric acid, 1g of boric acid, oxidized Magnesium 110g, silica 3g and lithopone 2g.

[0022] The preparation method of the starch glue is as follows: starch and water are heated and gelatinized at a mass ratio of 0.12-0.2:1.

[0023] The concentration of the magnesium sulfate solution is 17-25 ° of Baume.

[0024] The emulsifier is fatty alcohol polyoxyethylene ether, preferably OS-15.

[0025] A preparation method of the above-mentioned plant fiber novel flame-retardant adhesive, comprising the following steps:

[0026] Step 1. Heat starch and water at a mass ratio of 0.12-0.2:1 to 70-90°C for gelatinization, then cool to room temperature to prepare starch glue;

[0027] Step 2, stirring and mixing lithopone, trisodium phosphate...

Embodiment 2

[0030] A new type of flame-retardant adhesive for plant fibers, comprising the following components: 3g of trisodium phosphate, 50g of magnesium sulfate solution, 5g of calcium hydroxide, 4g of emulsifier, 75g of starch glue, 28g of phenolic resin, 4g of tartaric acid, 3g of boric acid, oxidized Magnesium 118g, silica 4g and lithopone 3g.

[0031] The preparation method of the starch glue is as follows: starch and water are heated and gelatinized at a mass ratio of 0.12-0.2:1.

[0032] The concentration of the magnesium sulfate solution is 17-25 ° of Baume.

[0033] The emulsifier is fatty alcohol polyoxyethylene ether, preferably OS-15.

[0034] A preparation method of the above-mentioned plant fiber novel flame-retardant adhesive, comprising the following steps:

[0035] Step 1. Heat starch and water at a mass ratio of 0.12-0.2:1 to 70-90°C for gelatinization, then cool to room temperature to prepare starch glue;

[0036] Step 2, stirring and mixing lithopone, trisodium p...

Embodiment 3

[0039] A new type of plant fiber flame retardant adhesive, comprising the following components: 2g of trisodium phosphate, 35g of magnesium sulfate solution, 4g of calcium hydroxide, 2g of emulsifier, 22g of starch glue, 12g of phenolic resin, 2g of tartaric acid, 2g of boric acid, oxidation Magnesium 105g, silica 2g and lithopone 1g.

[0040] The preparation method of the starch glue is as follows: starch and water are heated and gelatinized at a mass ratio of 0.12-0.2:1.

[0041] The concentration of the magnesium sulfate solution is 17-25 ° of Baume.

[0042] The emulsifier is fatty alcohol polyoxyethylene ether, preferably OS-15.

[0043] A preparation method of the above-mentioned plant fiber novel flame-retardant adhesive, comprising the following steps:

[0044] Step 1. Heat starch and water at a mass ratio of 0.12-0.2:1 to 70-90°C for gelatinization, then cool to room temperature to prepare starch glue;

[0045] Step 2, stirring and mixing lithopone, trisodium phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com