A globe valve body with a partition structure

A globe valve, partition wall technology, applied in the valve shell structure, valve details, valve device and other directions, can solve the problems of shortening the service life of the valve body, stress seal leakage, etc., to achieve the effect of improving the service life and reliable valve seat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

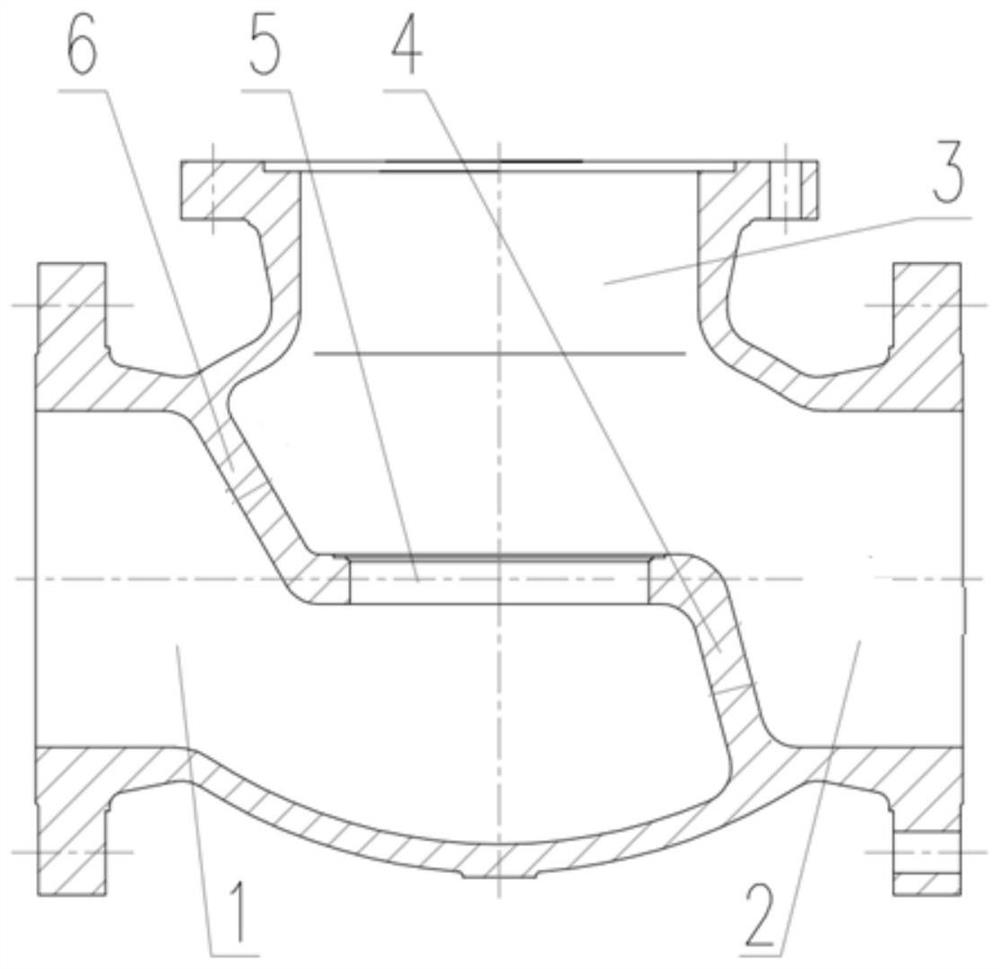

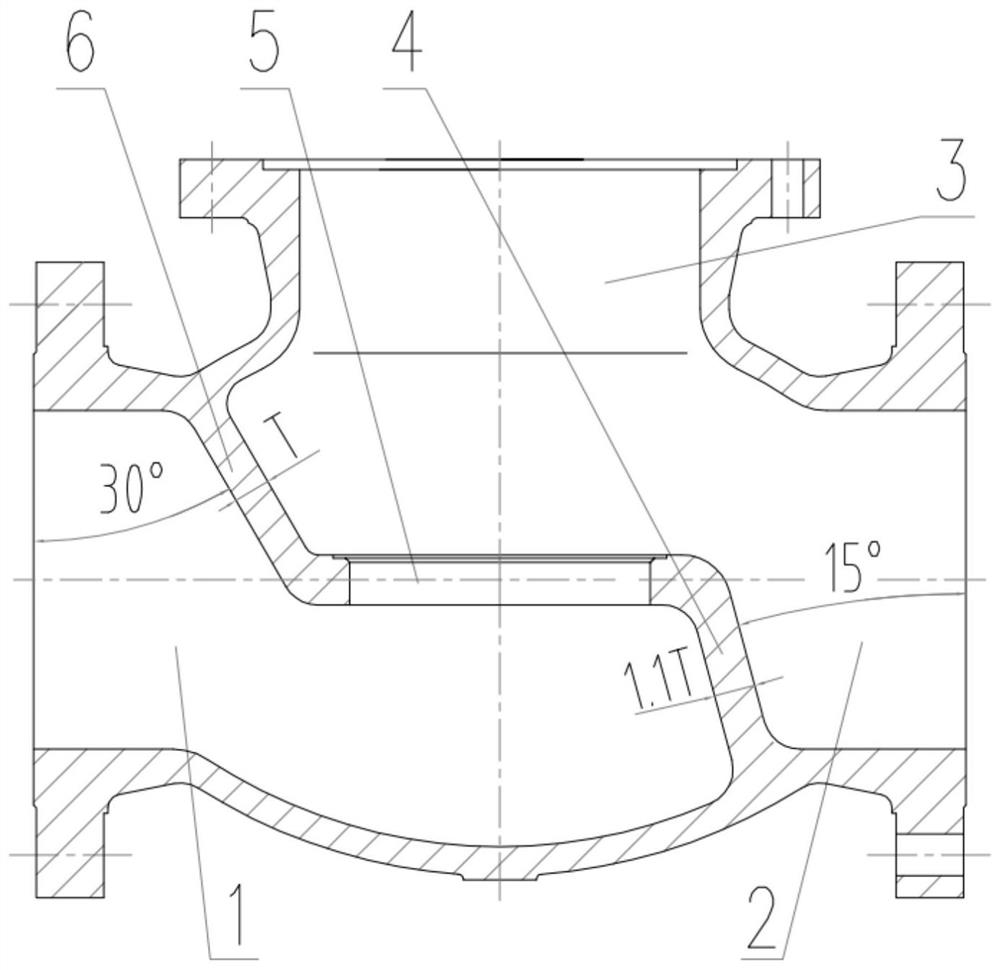

[0021] Such as figure 1 As shown, the inside of the valve body is a middle cavity 3, the upper end of the valve body is processed with an opening, and the two sides of the valve body are respectively processed with an inlet channel 1 and an outlet channel 2.

[0022] A partition wall and a valve seat 5 are processed inside the valve body. The partition wall and the valve seat 5 are fixedly connected as a whole, which divides the interior of the valve body into two parts. The outlet channel communicates with the opening at the upper end of the valve body.

[0023] There is a hole in the center of the valve seat 5, through which the inlet channel 1 and the outlet channel 2 in the valve body are communicated.

[0024] The overall structure composed of the partition wall and the valve seat 5 is further described.

[0025] The valve seat 5 divides the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com