Portable airtightness test method

An airtight test, portable technology, applied in liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of fluid, by detecting the appearance of fluid at the leakage point, etc., it can solve the problem of complicated equipment and unsuitable for portability Use and other issues, to achieve the effect of low environmental requirements, convenient transportation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

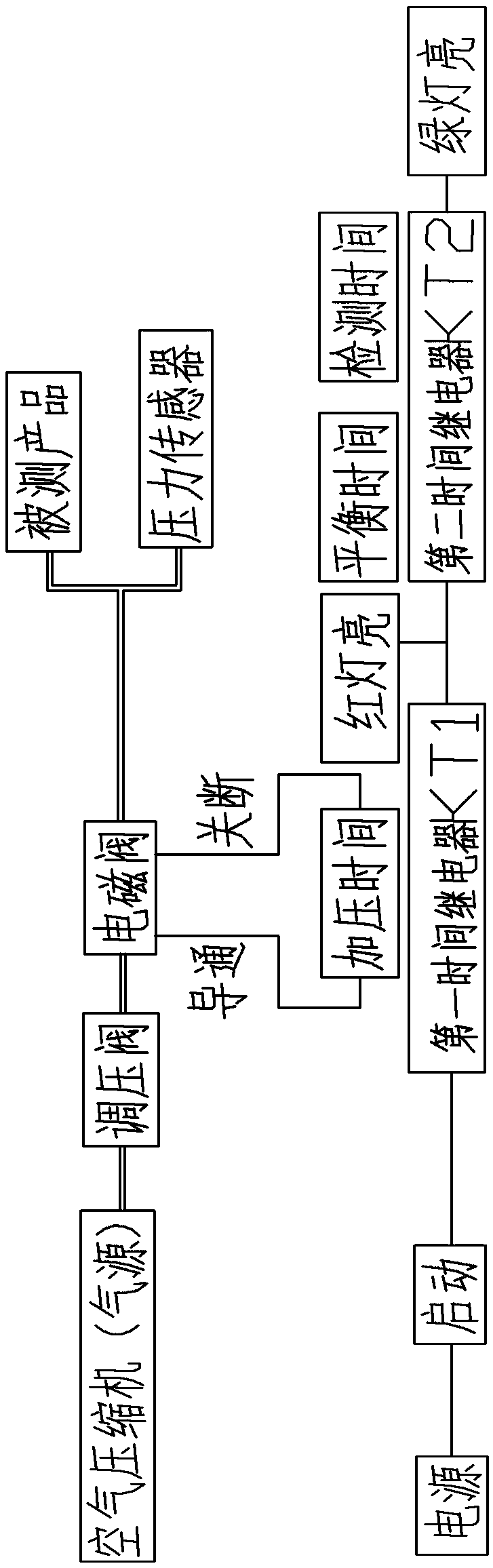

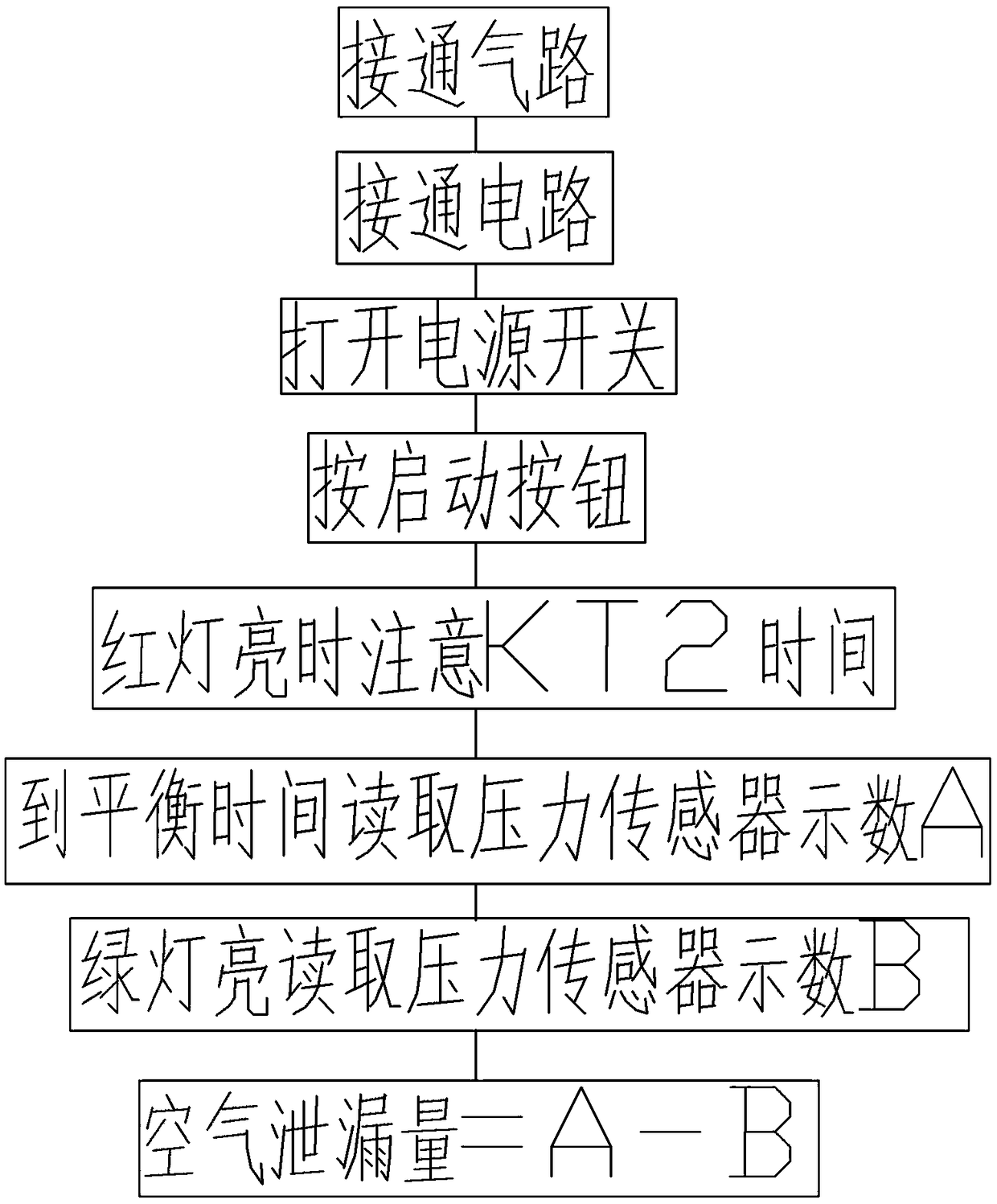

[0014] A portable airtight test method, which is characterized in that: the air outlet of the product under test is blocked, and then the product under test is inflated. Comparing the calculated maximum leakage within this time, you can determine whether the airtightness of the tested product itself is qualified or not; during the test, if the airtightness of the tested product is not qualified, keep the tested product in the state of inflating Put the tested product into the water to see if there are any bubbles, and the place with bubbles is the leak point; if the tested product is inconvenient to enter the water, apply soapy water to the place where the product may leak, and the place where the bubbles are generated is the leak point.

[0015] The specific operation is as follows. Calculate the maximum leakage value C in the preset detection time period according to the equivalent internal volume of the product under test. After the gas outlet of the product under test is bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com