Connecting piece with fine adjusting function

A connection and function technology, applied in the direction of connection components, threaded fasteners, screws, etc., can solve the problems of inability to adjust, the vibration frequency and amplitude are not identical, and not flexible enough to achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

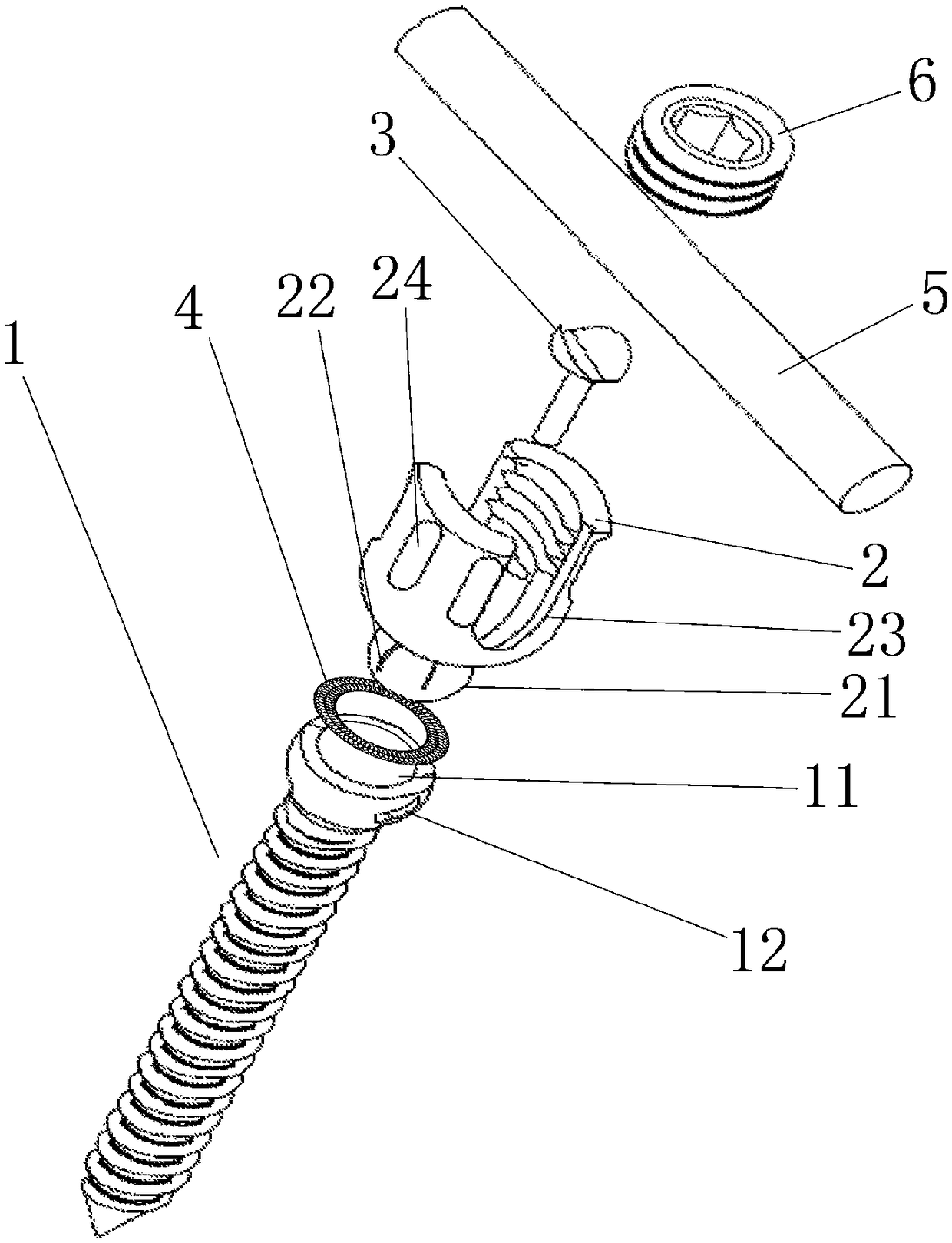

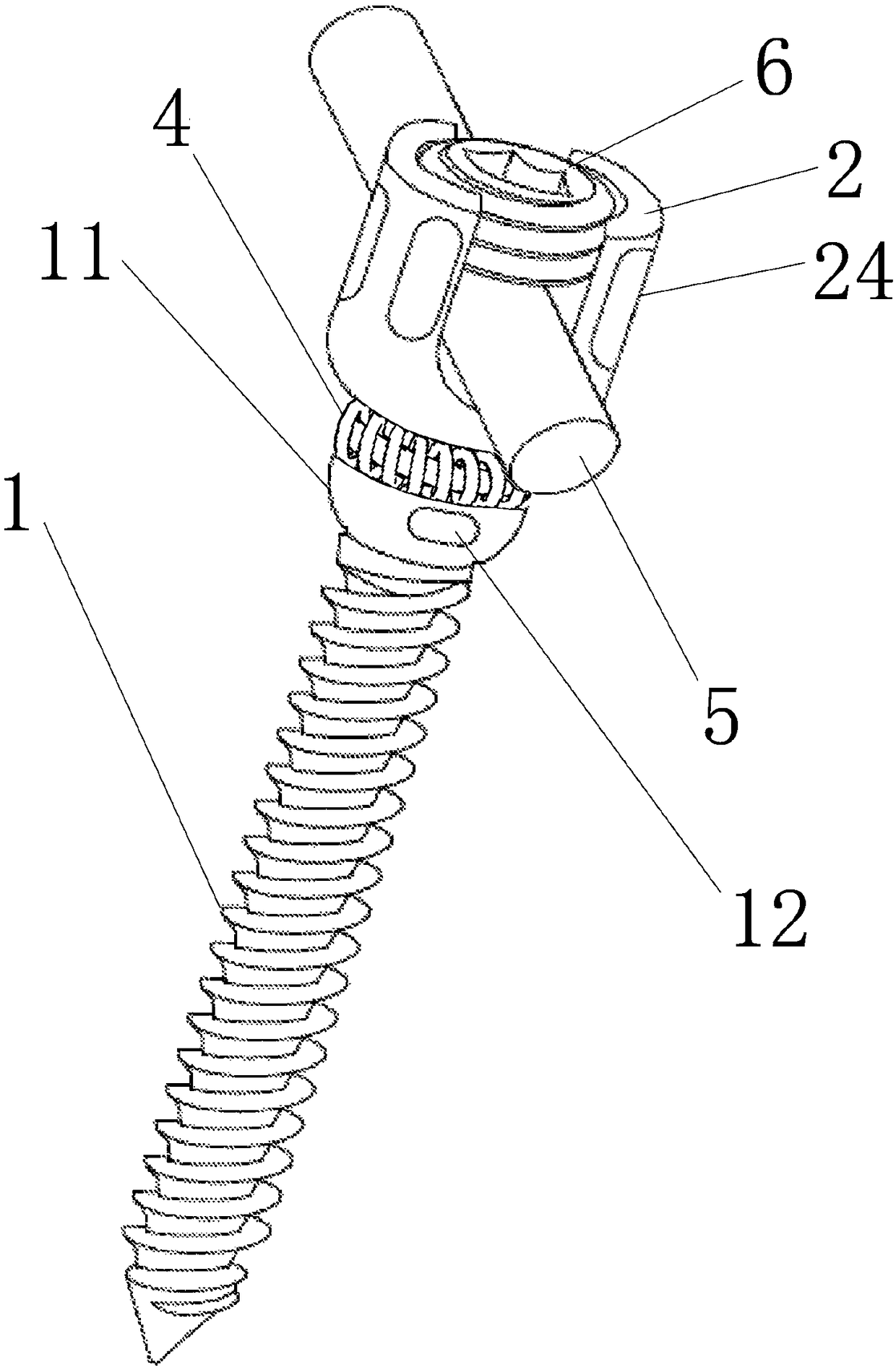

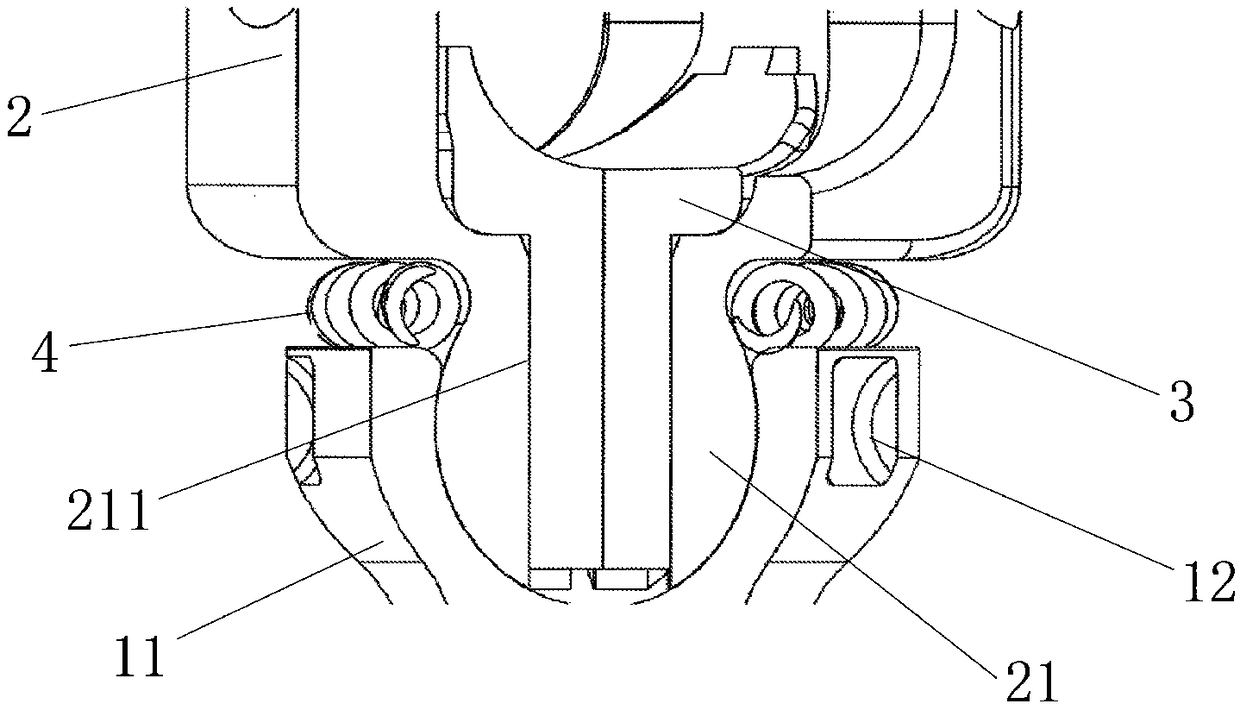

[0027] Such as Figures 1 to 3 As shown, this embodiment is composed of a screw 1, a supporting part 2, an expansion nail 3, a spring ring 4, a connecting rod 5 and a locking part 6, wherein the rear end of the screw 1 protrudes upwards to form an opening larger than a semicircle 11. The outer wall of the opening 11 is provided with an opening hollow 12; the supporting part 2 has a ladder-like structure as a whole and is made of elastic resin material, and is divided into the front end 21 of the supporting part and the rear end of the supporting part, and the front end of the supporting part The outer diameter of 21 is slightly smaller than the inner diameter of opening 11, the outer diameter of the rear end of the supporting part is larger than the outer diameter of opening 11, the front end 21 of the supporting part is in a large hemispherical shape matched with the opening 11, and the front end 21 of the supporting part is provided with a slit 22 , the middle part of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com