Method for calculating outline and contact angle of heavy liquid drop on horizontal regular double-roughness surface

A calculation method and roughness technology, which is applied to the calculation of the heavy droplet profile and contact angle on the horizontal regular double roughness surface, in the field of heavy droplet profile and contact angle on the horizontal regular double roughness surface, which can solve the accuracy limitation of the measuring device, Errors, operational accidental errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

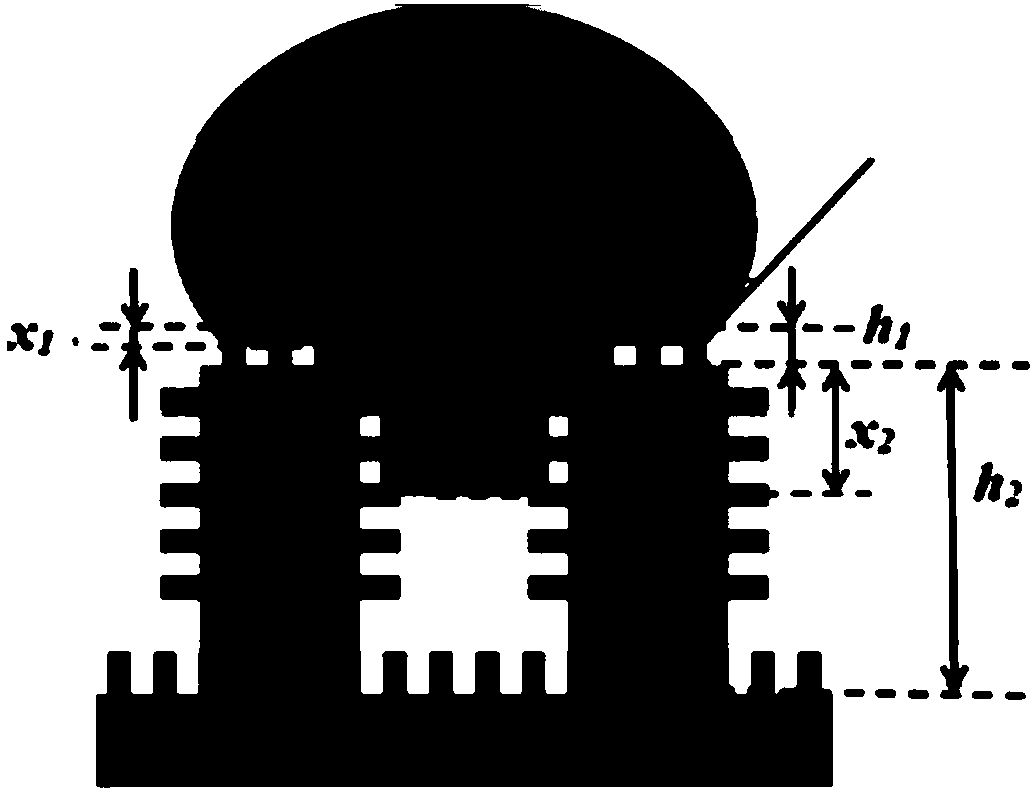

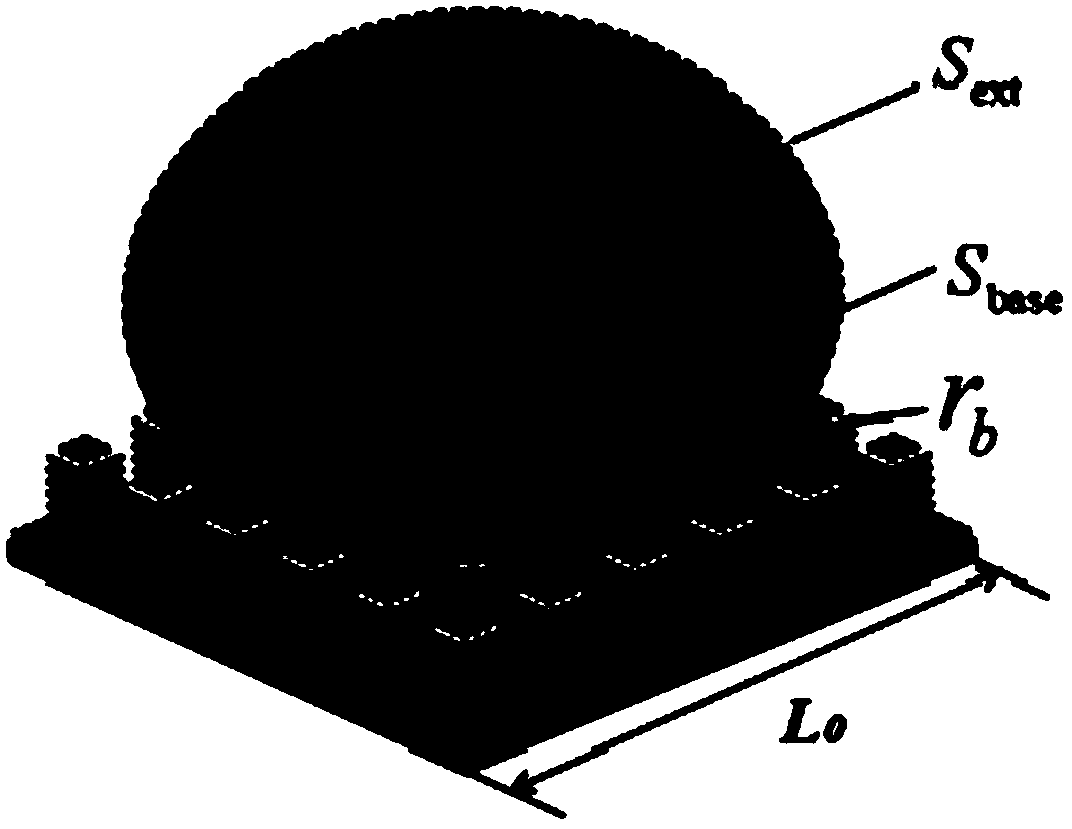

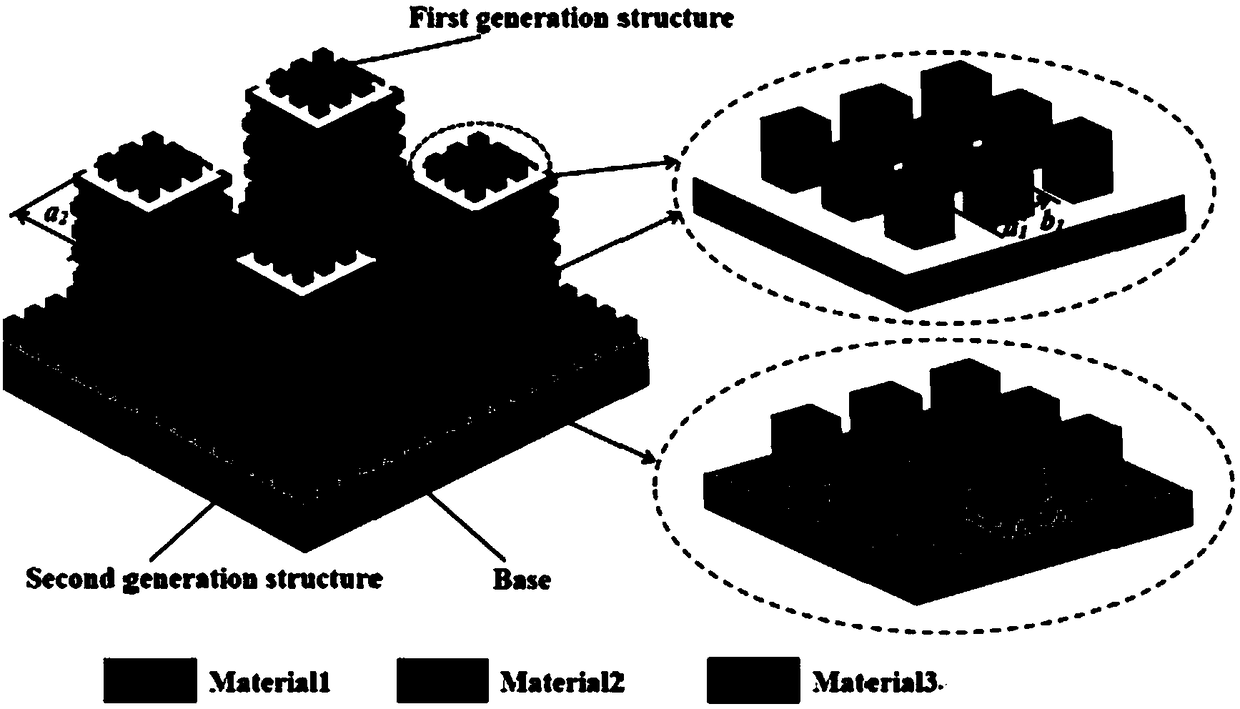

[0205] The geometric structure size parameters of the secondary structure are: the side length of the square column of the nanostructure is ɑ 1 = 100nm, period distance b of regular square matrix 1 = 88nm, the height h of the square column 1 =400nm, the side length of the square column with micron structure is ɑ 2 =10μm, periodic distance b of regular square matrix 2 =8.26μm, the height h of the square column 2 = 13 μm. The intrinsic contact angle of the droplet on the primary structure, secondary structure and substrate is θ e0 = θ e1 = θ e2 = 106°.

[0206] As shown in Fig. 4, we conducted experiments to measure the profiles of heavy liquid droplets of different volumes on lotus leaves. At the same time, the simulated section of the heavy droplet is calculated. Both experimental and simulation results show that the contours of heavy droplets on the same lotus leaf become flattened with increasing volume. The simulated droplet profile (red line) agrees well with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com