Combined two-piece lapel structure drawing method

A flip-up collar and two-piece technology, applied in the field of clothing design, can solve the problems of no fixed size parameters for the amount of return, increase the production process and work stations, unfavorable application and promotion, etc., achieve accurate and reasonable parameter design, and improve production Efficiency and effectiveness, the effect of increasing technology promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The drawing ratio is 1:1, and the kraft paper is made in cm.

[0018] The specific drawing steps are as follows:

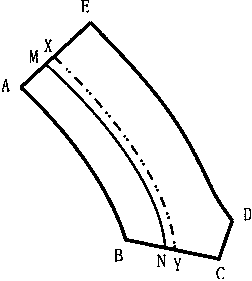

[0019] figure 1 The middle ABCDE is a one-piece turn-over collar model, the arc XY is the collar turn-over line, take MX=NY=0.7cm, and draw the arc MN so that MN∥XY, using MN as the cutting line, divide one collar into two There are two drawing templates, namely the undercollar template ABNM and the collar template M'N'CDE, where AB is the lower neckline, MN is the upper neckline, and DE is the outer neckline.

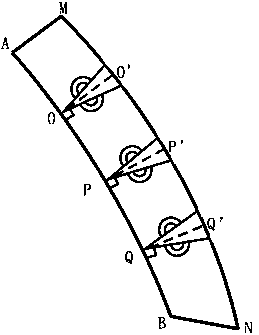

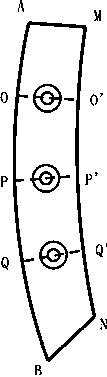

[0020] Such as figure 2 As shown, take quarter points O, P, and Q on the lower neckline AB, and cross the three points O, P, and Q respectively to make a straight line to cross the neckline MN at points O', P', and Q', so that The three line segments OO', PP' and QQ' are perpendicular to the tangent line of the arc AB at the three points O, P or Q respectively.

[0021] Take the three points O', P', and Q'as the reference respectively, take 0.15cm on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com