Gas-based shaft furnace, gas-based reduction-oxidation pellet system and method of using the system

A gas-based shaft furnace and oxidizing pellet technology, which is applied in the field of iron and steel metallurgy, can solve the problems affecting the operation rate of equipment, bonding, and errors in distribution, and achieve the effects of improving preheating effect, uniform distribution, and increasing carburizing amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

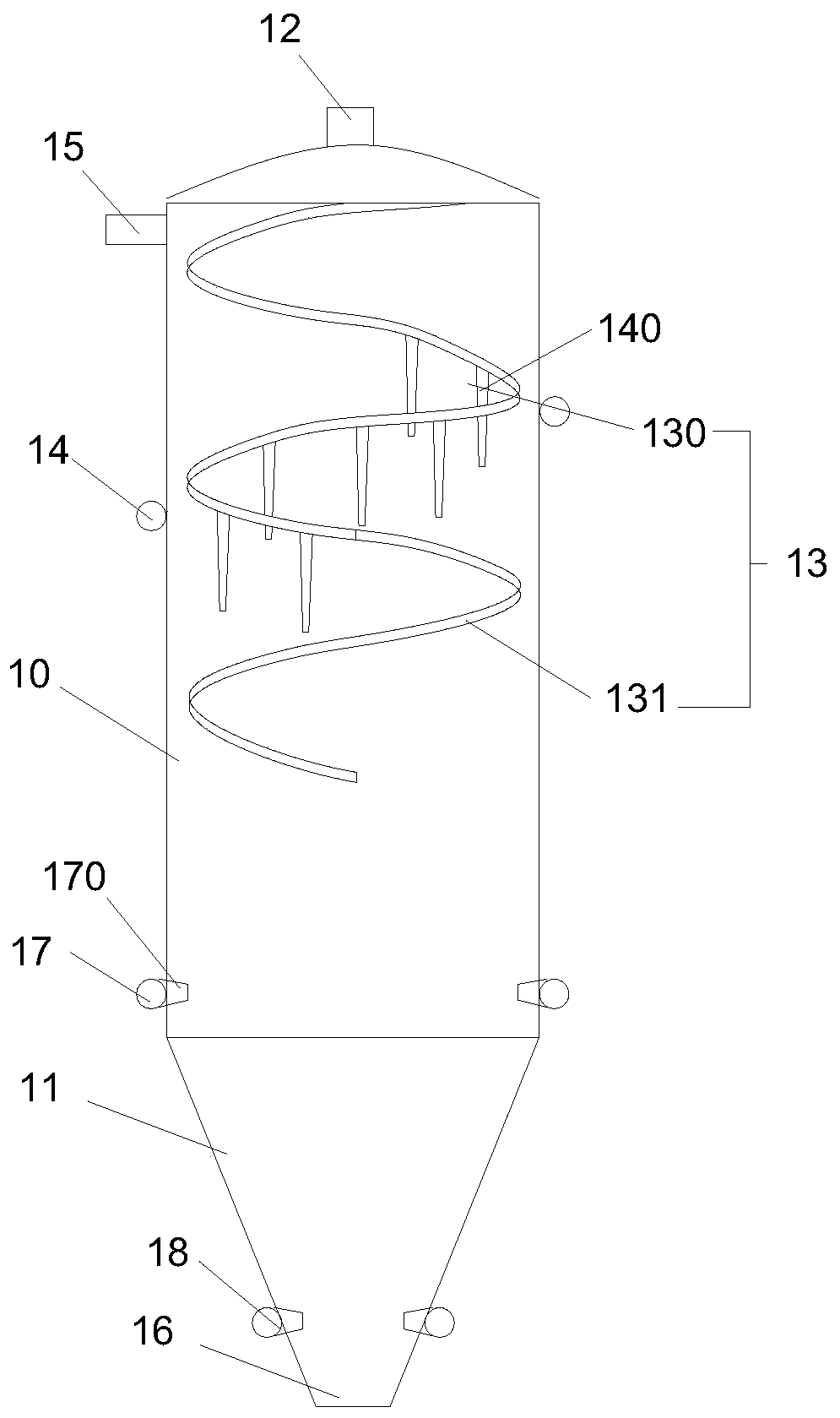

[0037] A gas-based shaft furnace such as figure 1 As shown, the inner chamber of the furnace includes a reduction section 10 and a cooling section 11, and the reduction section 10 includes:

[0038] The oxidized pellet inlet 12 located at the upper end of the inner cavity;

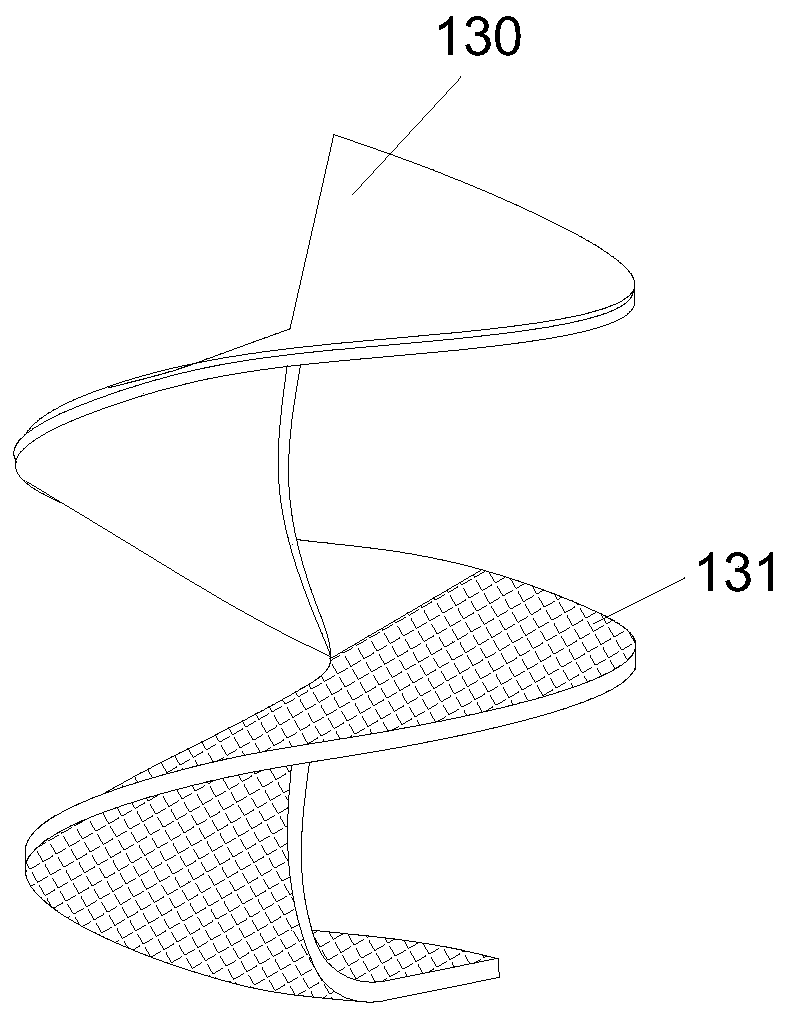

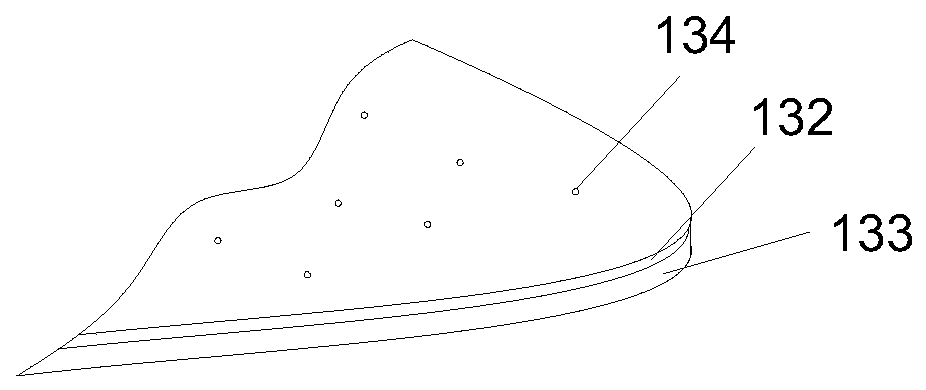

[0039] From the lower end of the oxidized pellet inlet 12 to the middle of the inner cavity, a spiral slideway 13 meandering downward is arranged. The upper part of the spiral slideway 13 is a curved surface 130, and the lower part is a grid part 131, as shown in FIG. figure 2 shown;

[0040] Surrounding the first surrounding pipe 14 outside the middle of the furnace body, the first nozzle 140 of the first surrounding pipe 14 extends into the inner cavity;

[0041] Surrounding the second surrounding pipe 17 outside the lower part of the furnace body, the second surrounding pipe 17 is arranged below the first surrounding pipe 14, and it is provided with a second nozzle 170 extending into the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com