Ventilation ball base structure corresponding to building heat dissipation cover

A heat dissipation cover, building technology, applied in the direction of space heating and ventilation, heating and ventilation cover/cover, space heating and ventilation details, etc., can solve the problems of laborious and costly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure, features and embodiments of the present invention are described below with the aid of drawings, so that examiners can have a better understanding of the present invention.

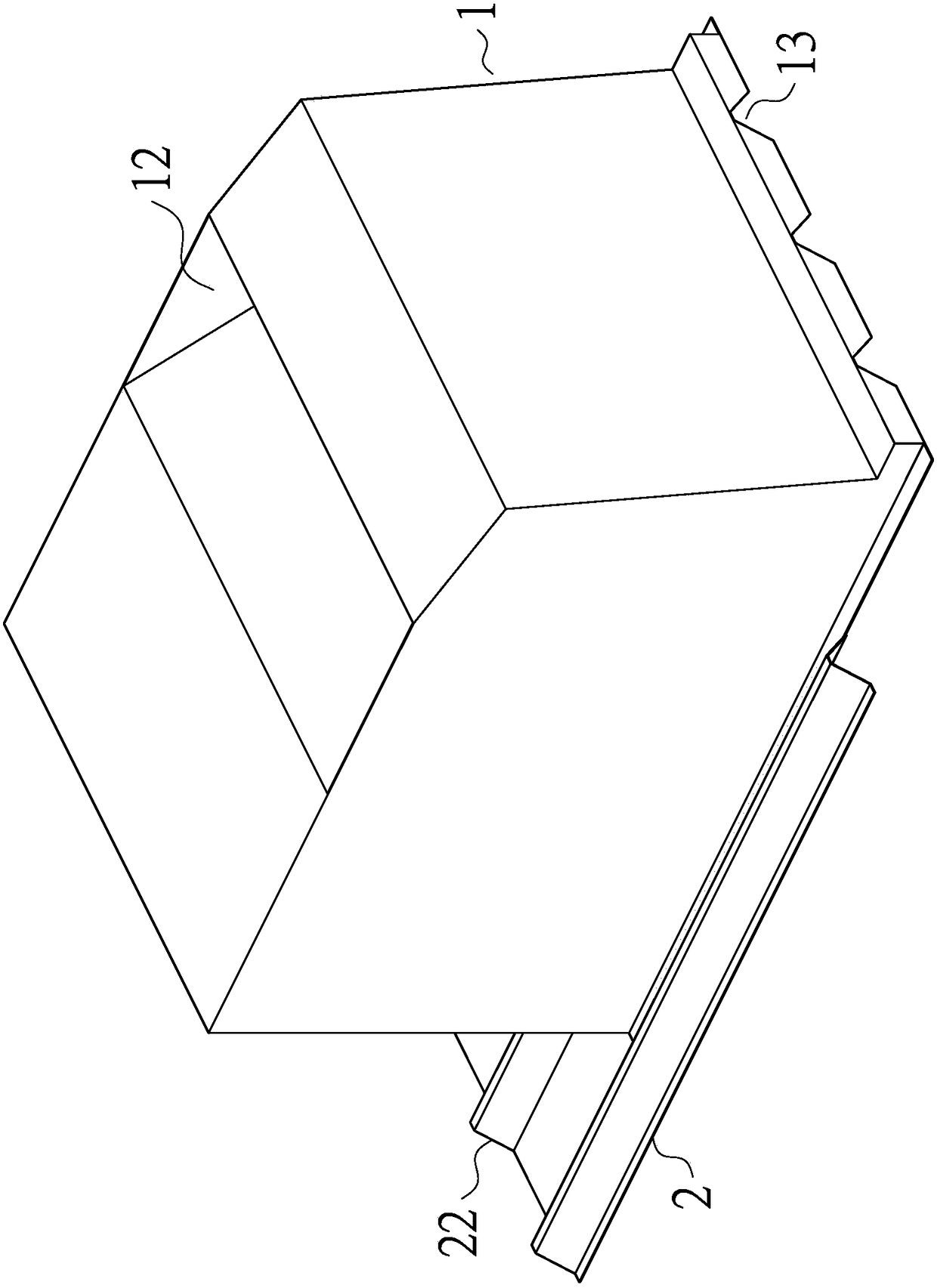

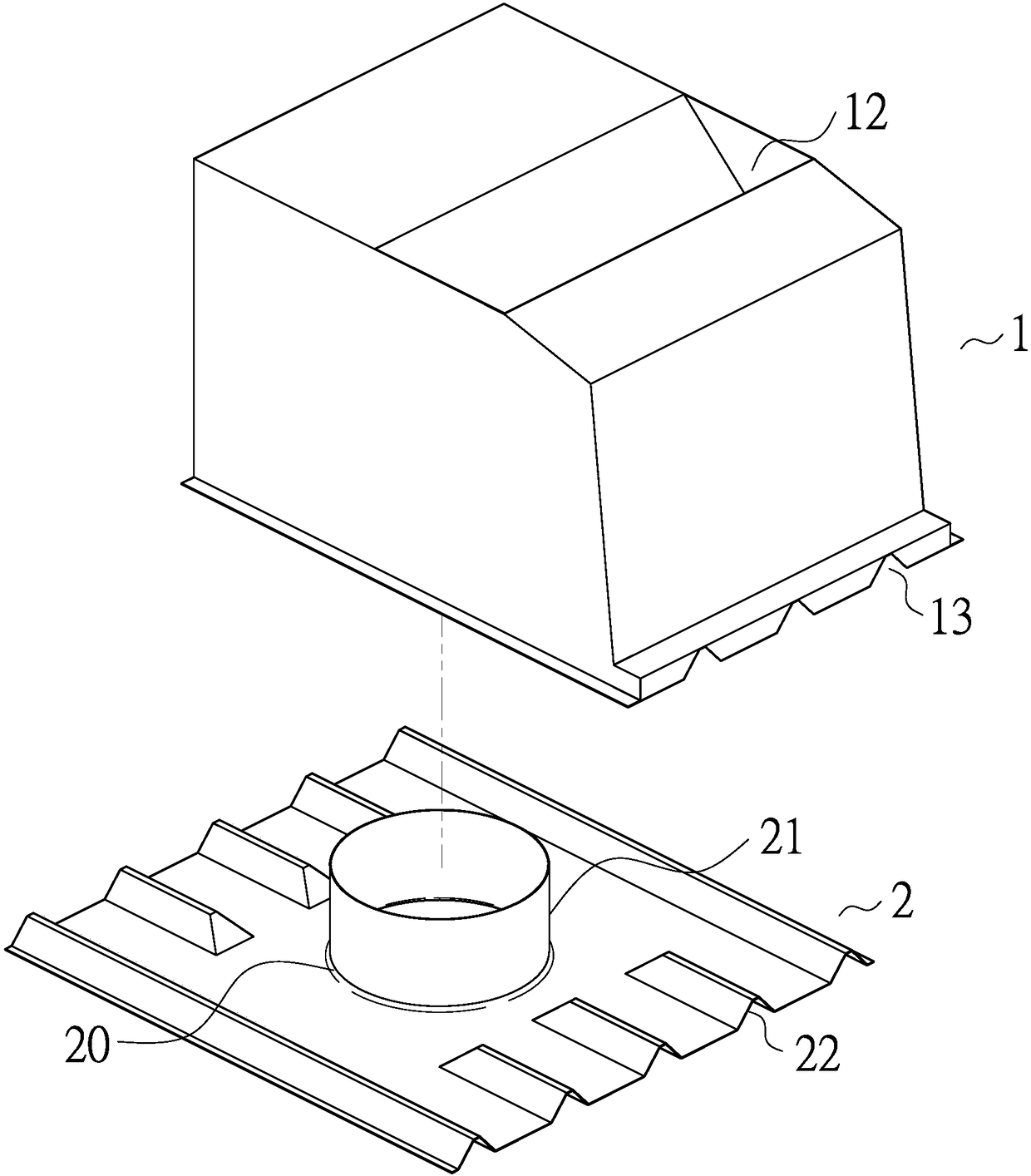

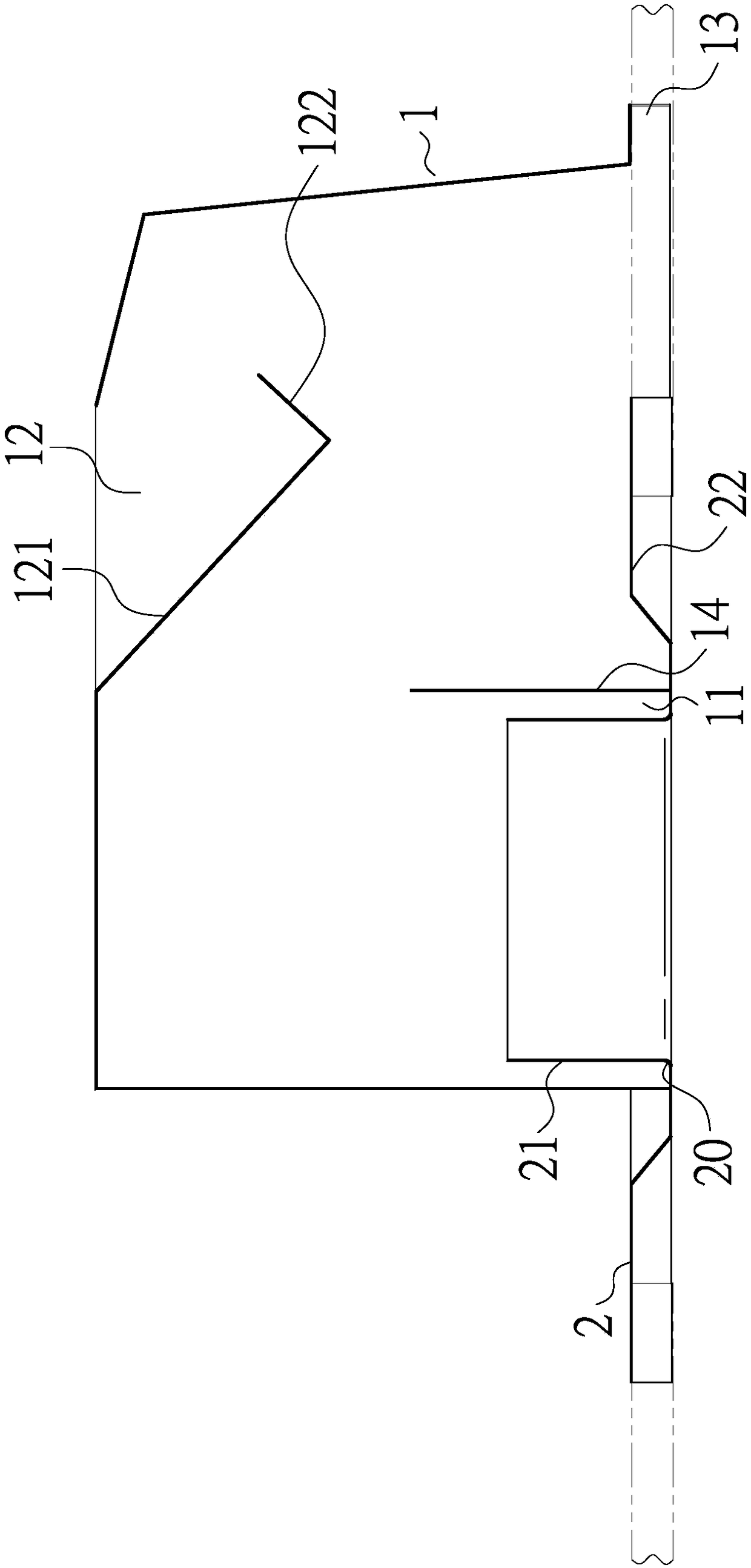

[0025] see figure 1 ,Cooperate figure 2 As shown, the present invention relates to a construction of a building heat dissipation cover corresponding to a ventilation ball base structure, including a heat dissipation cover main body 1, and the heat dissipation cover main body 1 includes an air inlet hole 11 for matching image 3 The air inlet 11 can be framed by the shell wall of the heat dissipation cover main body 1 and a partition plate 14 provided between the two symmetrical shell walls of the heat dissipation cover main body 1, and the heat dissipation cover main body 1 includes an air outlet hole 12 , and the air inlet hole 11 and the air outlet hole 12 form an exhaust path, one side of the air outlet hole 12 extends obliquely downward toward the main body 1 of the heat dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com