Patents

Literature

71results about How to "Reduce outgoing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

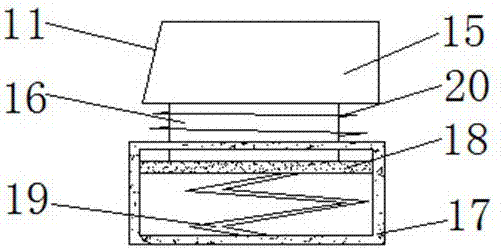

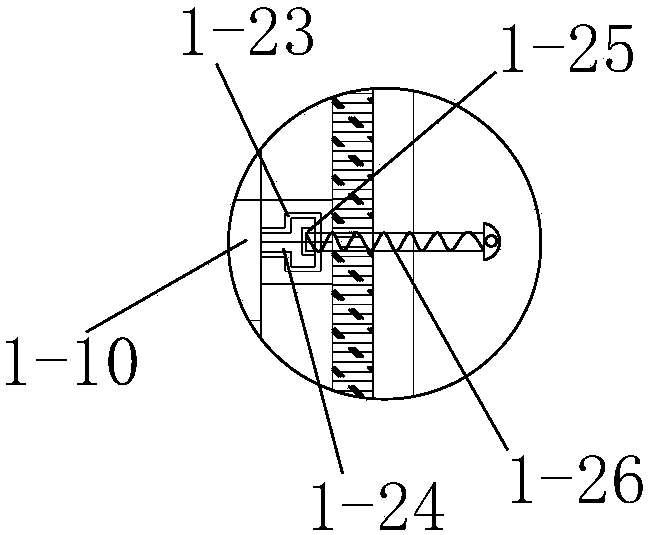

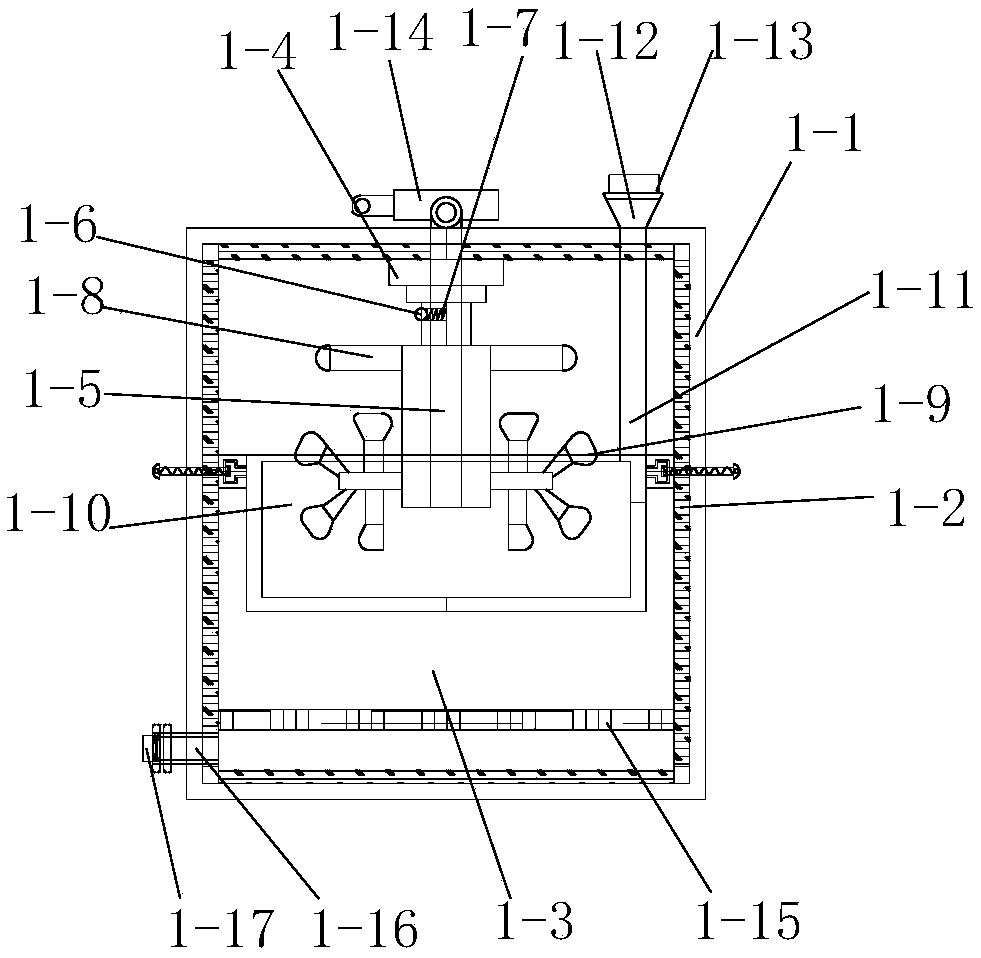

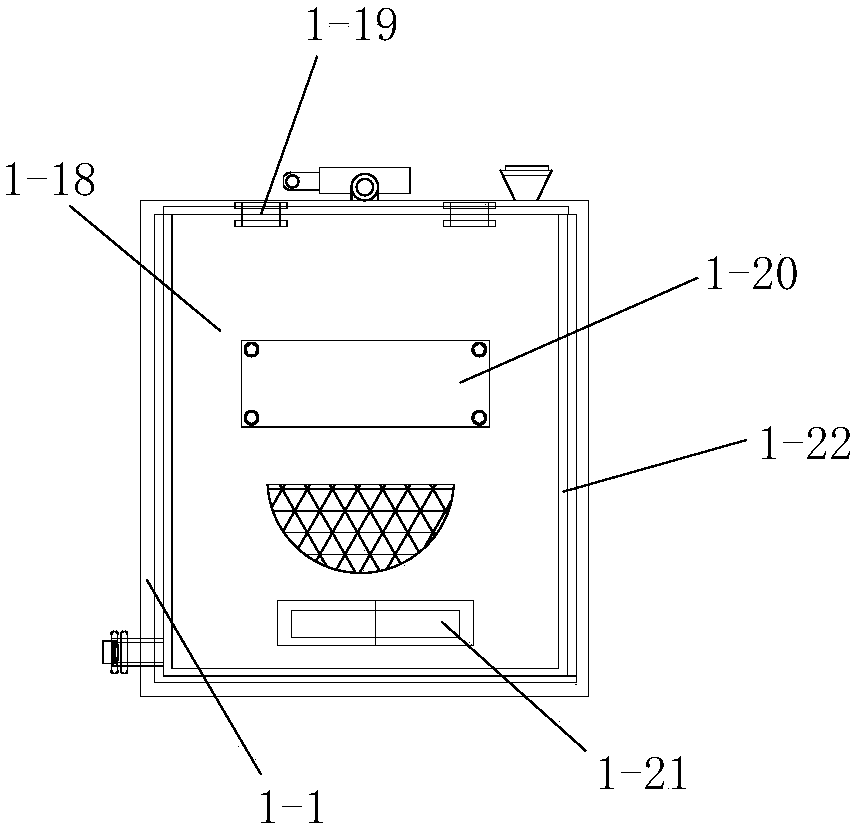

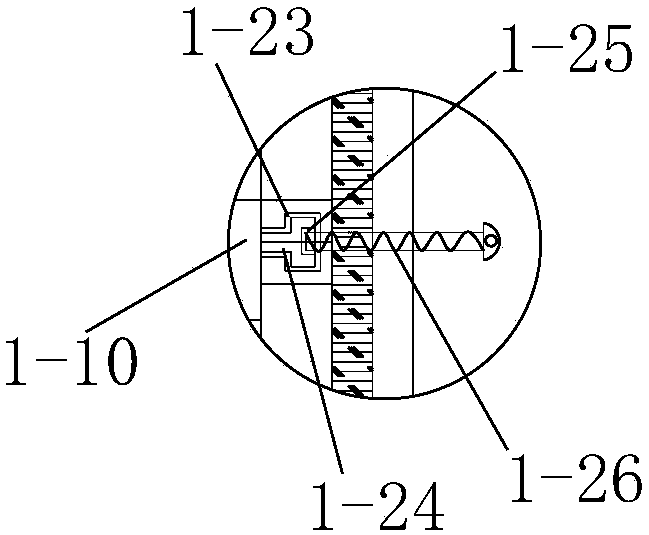

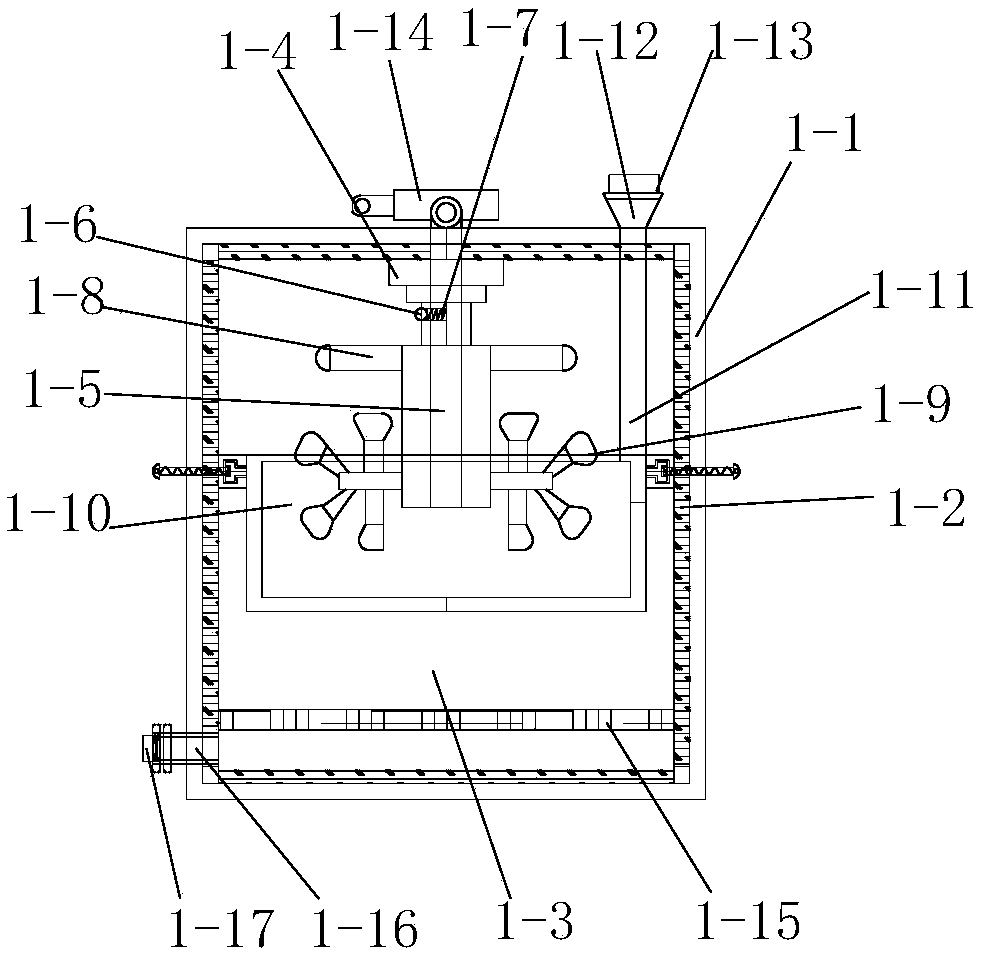

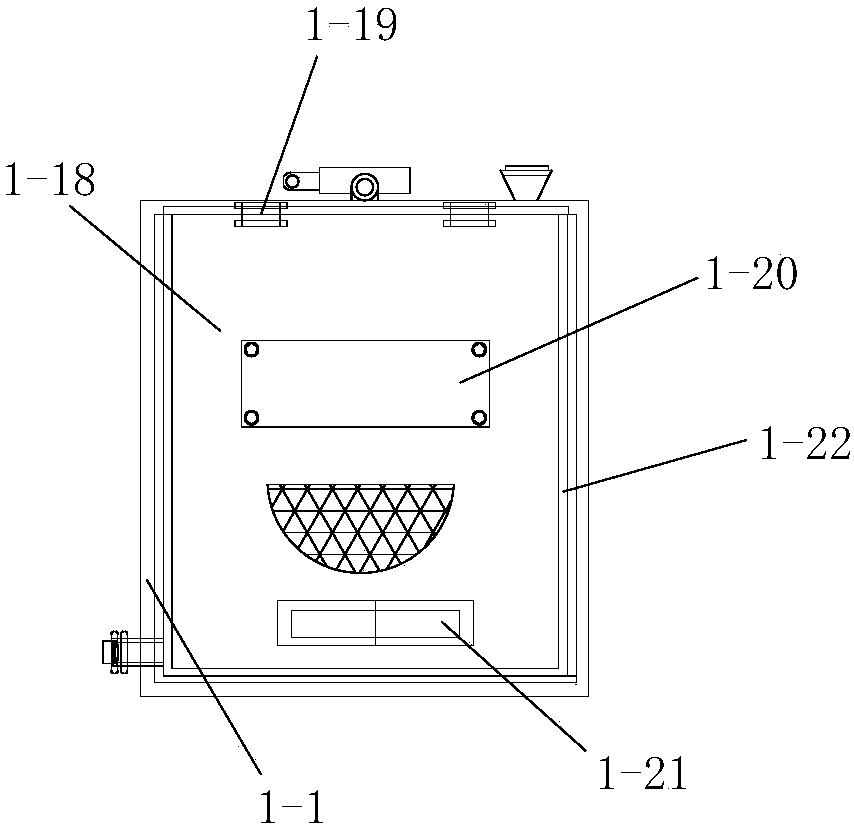

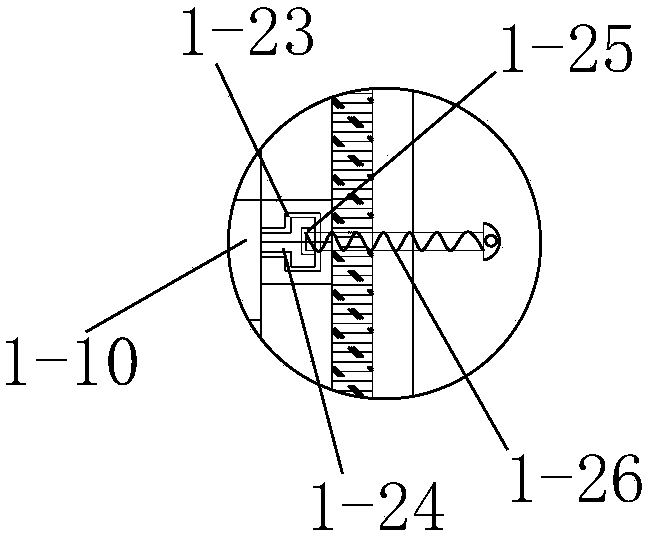

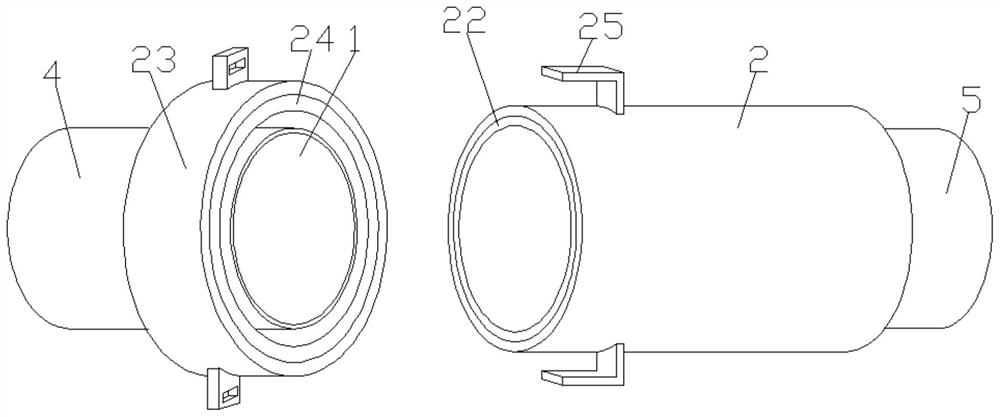

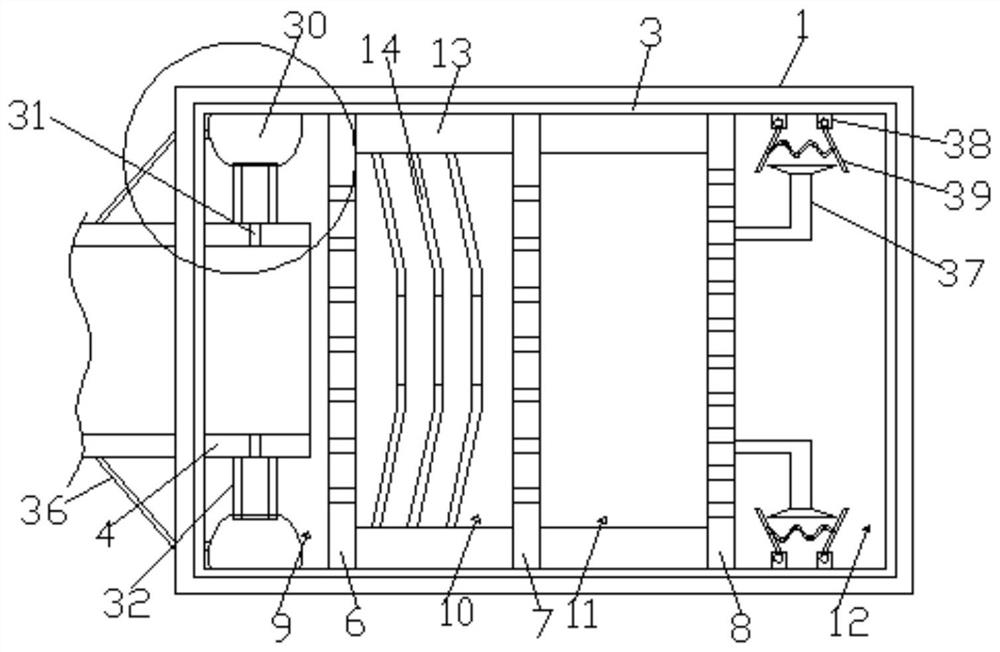

Fan device and breathing machine with same

ActiveCN103807221AReduce in quantityReduce outgoingRespiratorsPump componentsLow noiseEmbedded system

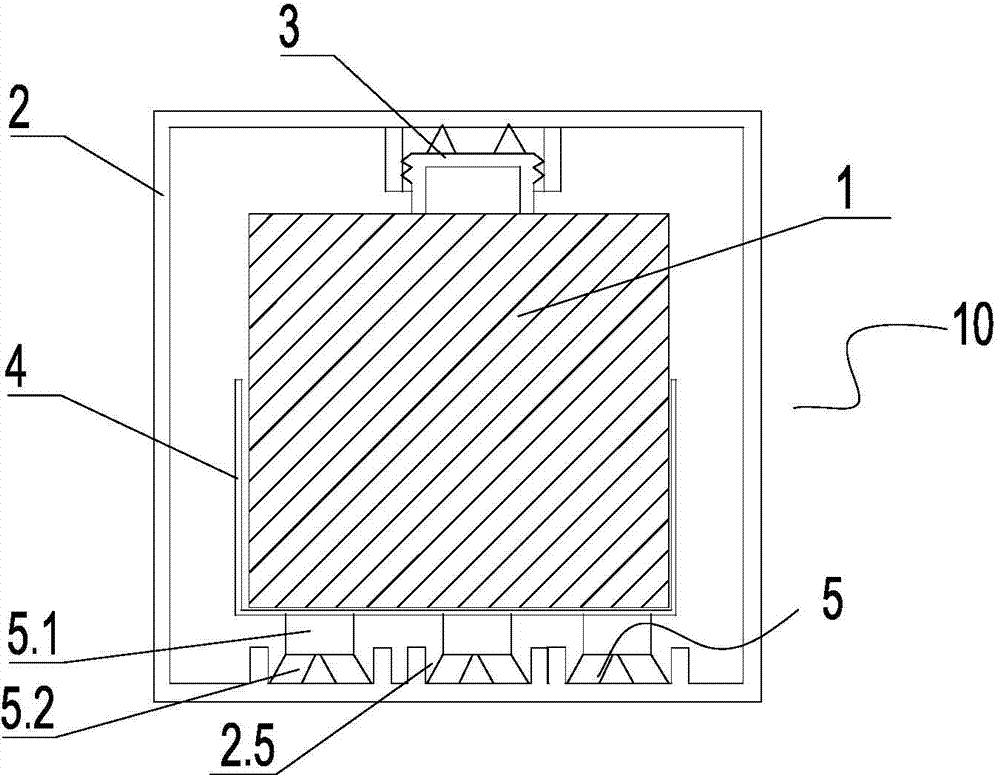

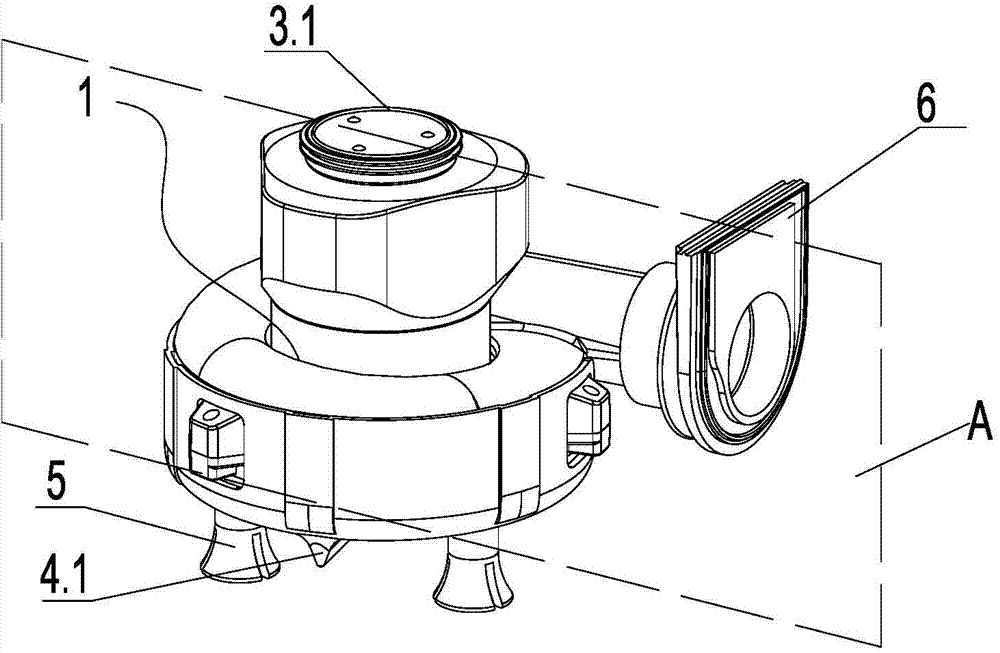

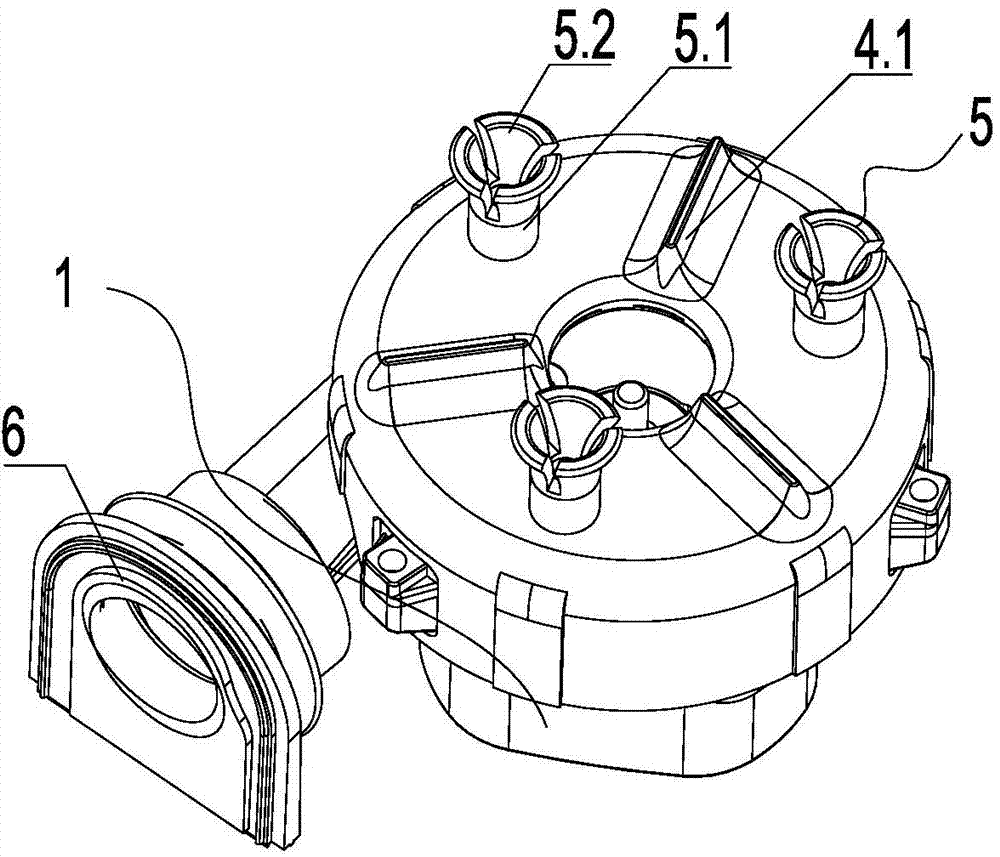

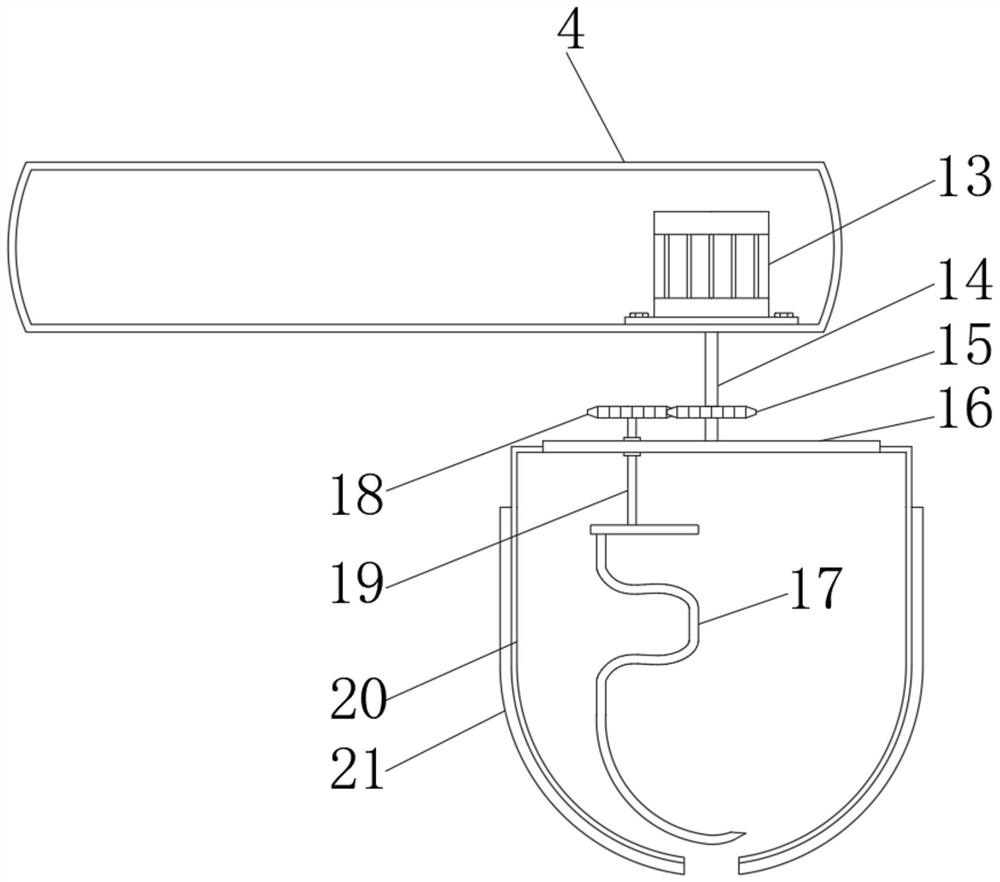

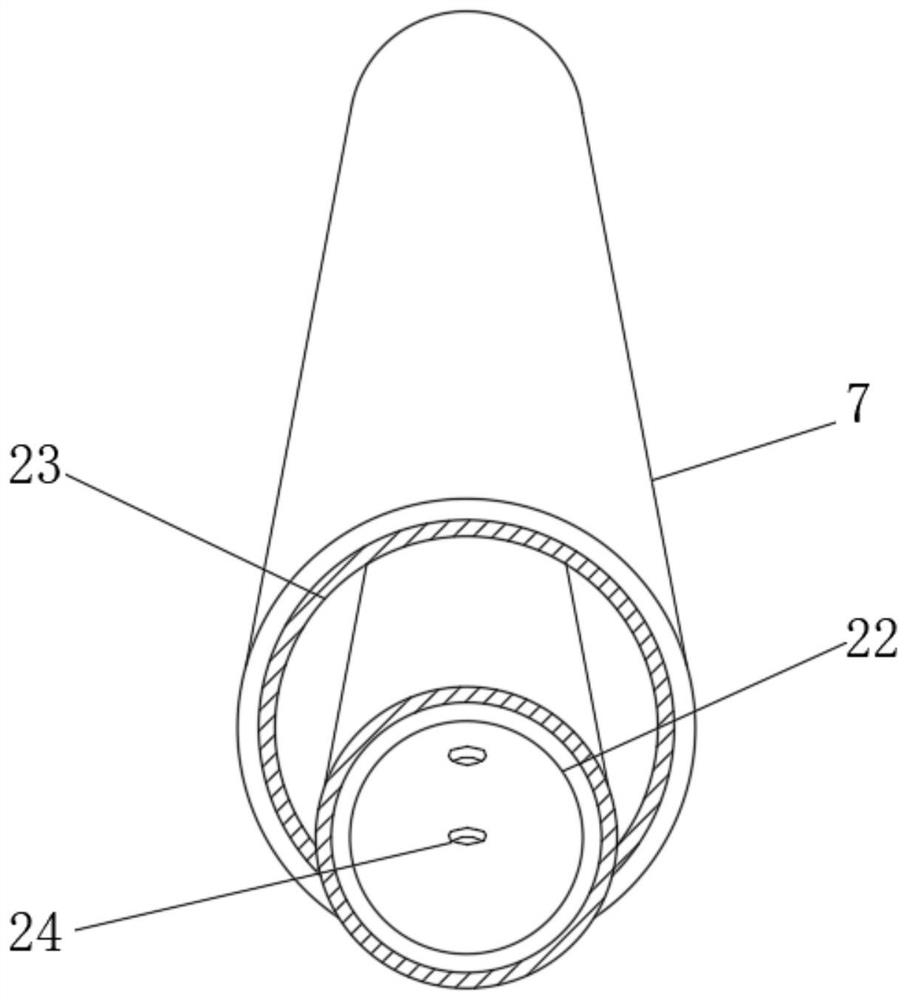

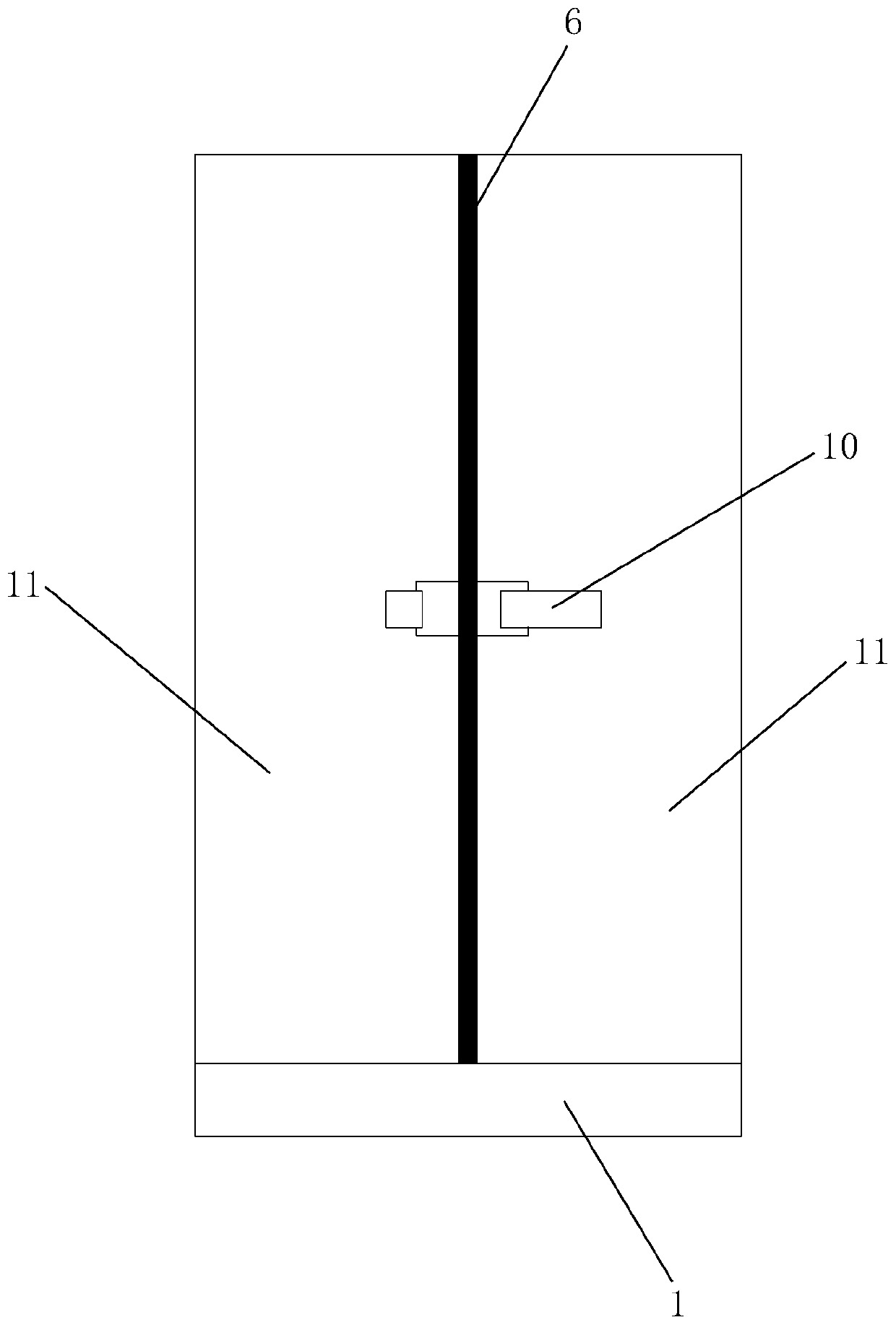

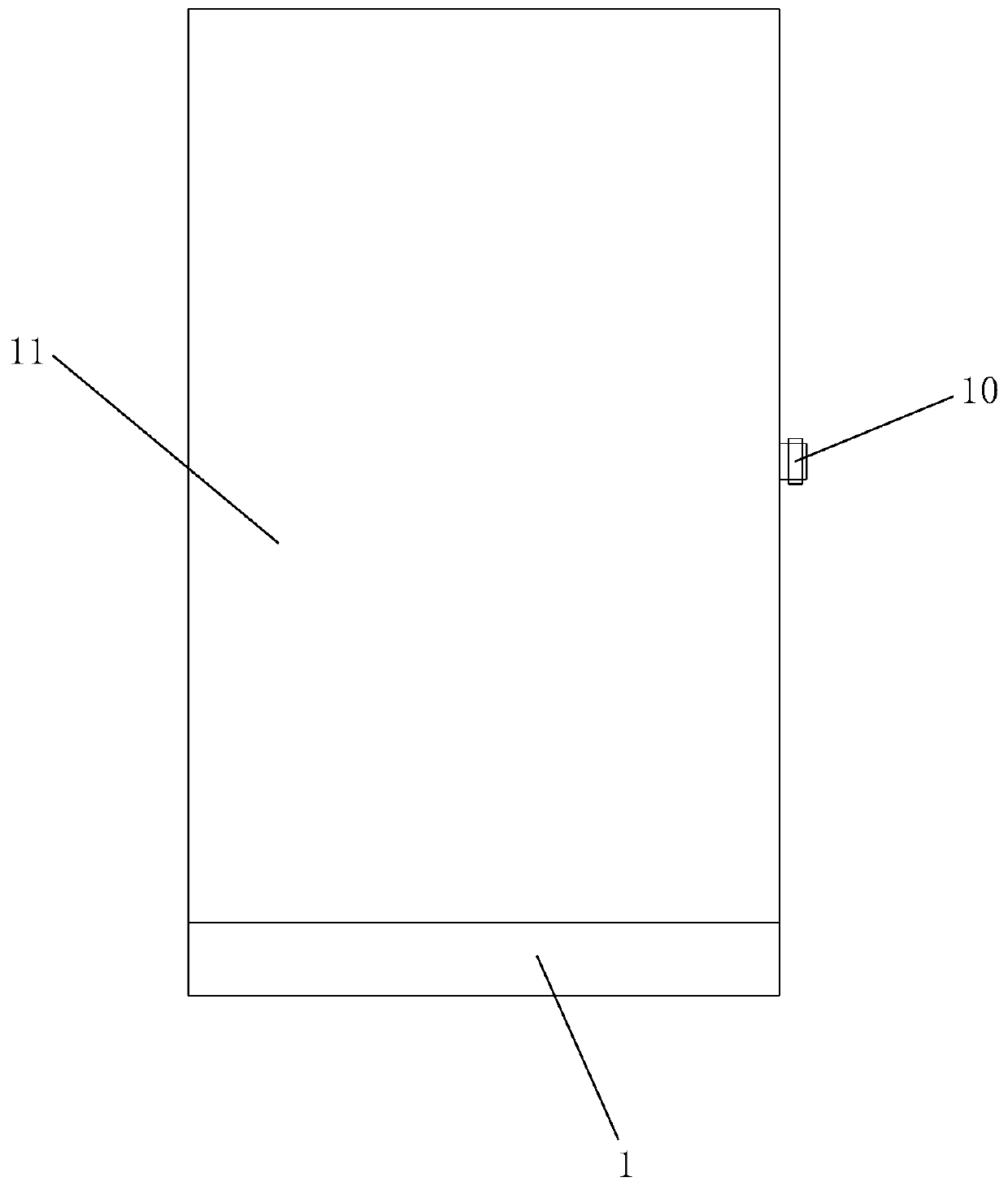

The invention discloses a fan device and a breathing machine with the same. The fan device comprises a shell, a fan vibration source and a buffer assembly, wherein the fan vibration source is arranged in the shell, the buffer assembly is used for enabling the fan vibration source to be connected with the shell, and the buffer assembly comprises at least two of a positioning buffer component connected with the top of the fan vibration source, a connecting buffer component which at least partly contains the fan vibration source, and a supporting buffer component which is connected with the bottom of the fan vibration source. The fan device can effectively buffer vibration of a fan and reduce and lower noise transmission and is simple in structure.

Owner:BMC MEDICAL

Water-based high-temperature-resistant antirust paint and preparation method thereof

InactiveCN104559670AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsPropanoic acidSodium phosphates

The invention discloses a water-based high-temperature-resistant antirust paint. The water-based high-temperature-resistant antirust paint is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of sodium propionate, 2-3 parts of sodium pyrophosphate, 4-6 parts of mica powder, 2-3 parts of propanediol butyl ether, 23-26 parts of styrene-acrylic emulsion, 1-2 parts of 18-alkyl primary amine acetate, 0.3-0.5 part of organic fluoride modified polysiloxane, 1-2 parts of zinc stearate, 2-3 parts of carbonate pickax, 0.3-0.5 part of sodium oleate, 2-3 parts of polyving akohol, 2-3 parts of a water-based curing agent D230, 0.1-0.3 part of polyxyethylated alkylphenol, 33-36 parts of epoxy resin emulsion, 3-4 parts of barite powder, 4-7 parts of talcum powder, 16-22 parts of deionized water and 4-7 parts of an additive. After the paint is solidified, a paint film is high in hardness, good in abrasive resistance, high in adhesive force and not easy to peel off and also has the functions of resisting high temperature and preventing rust. By utilizing the water-based high-temperature-resistant antirust paint, an out door device shell can withstand harsh environment, the service life is prolonged, the added additive has the effect of reducing noise through damping, outflow of noise is weakened, and harmonious living environment is built.

Owner:安徽省东瑞装饰材料有限公司

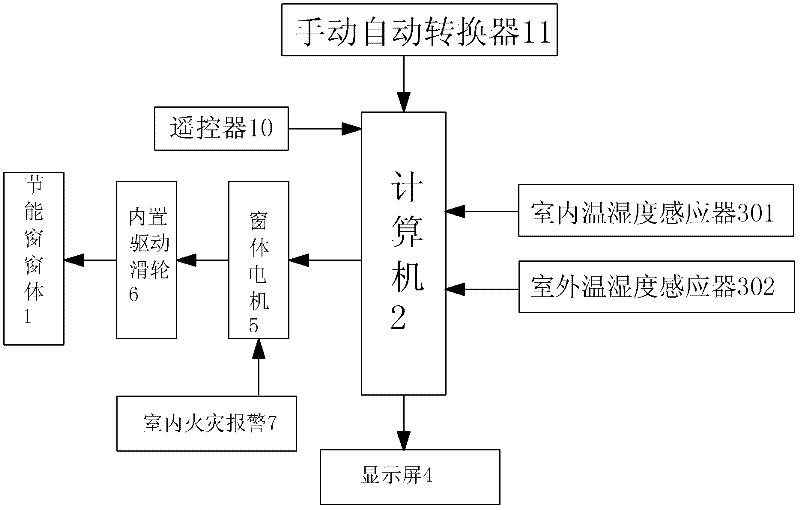

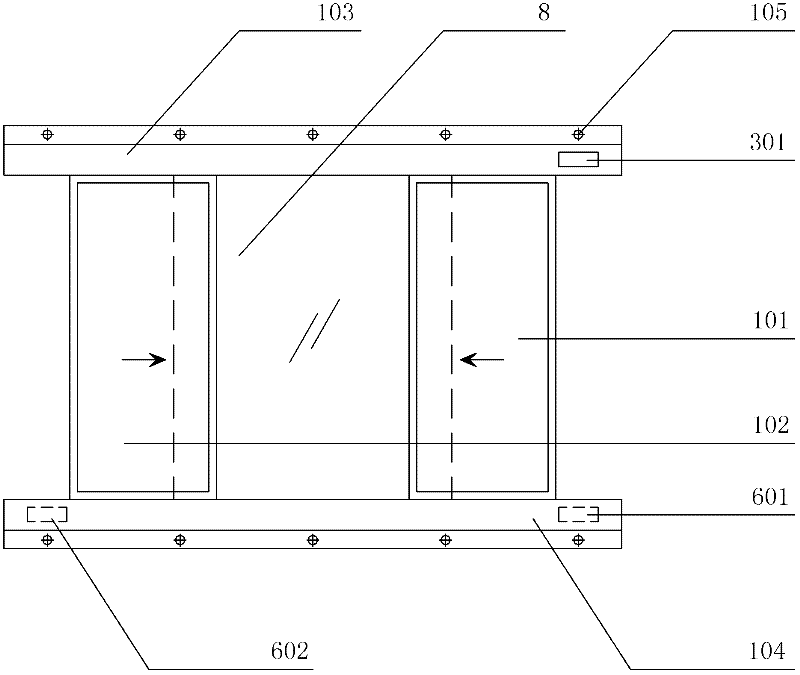

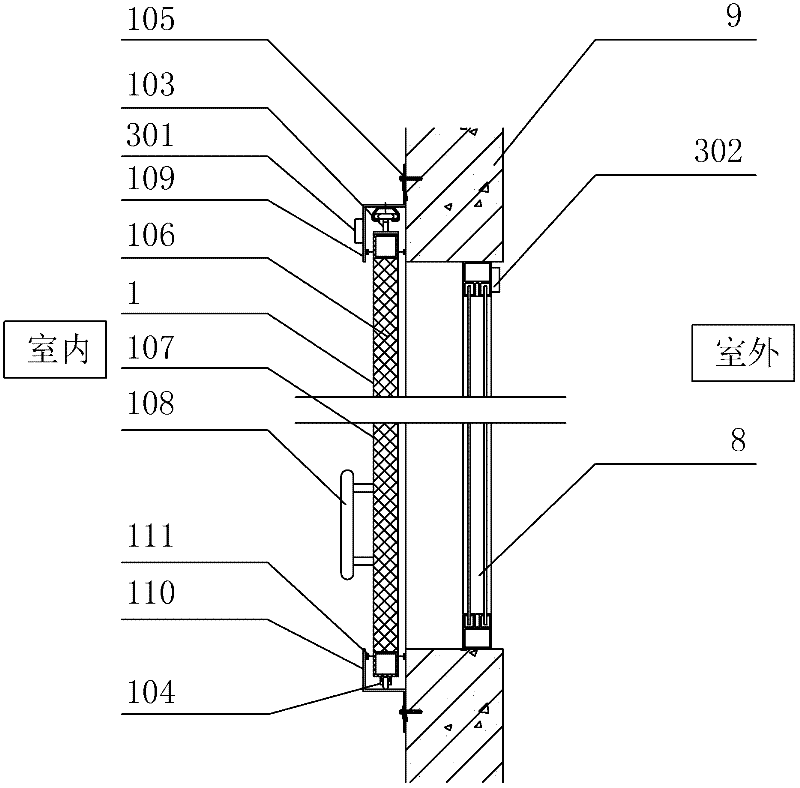

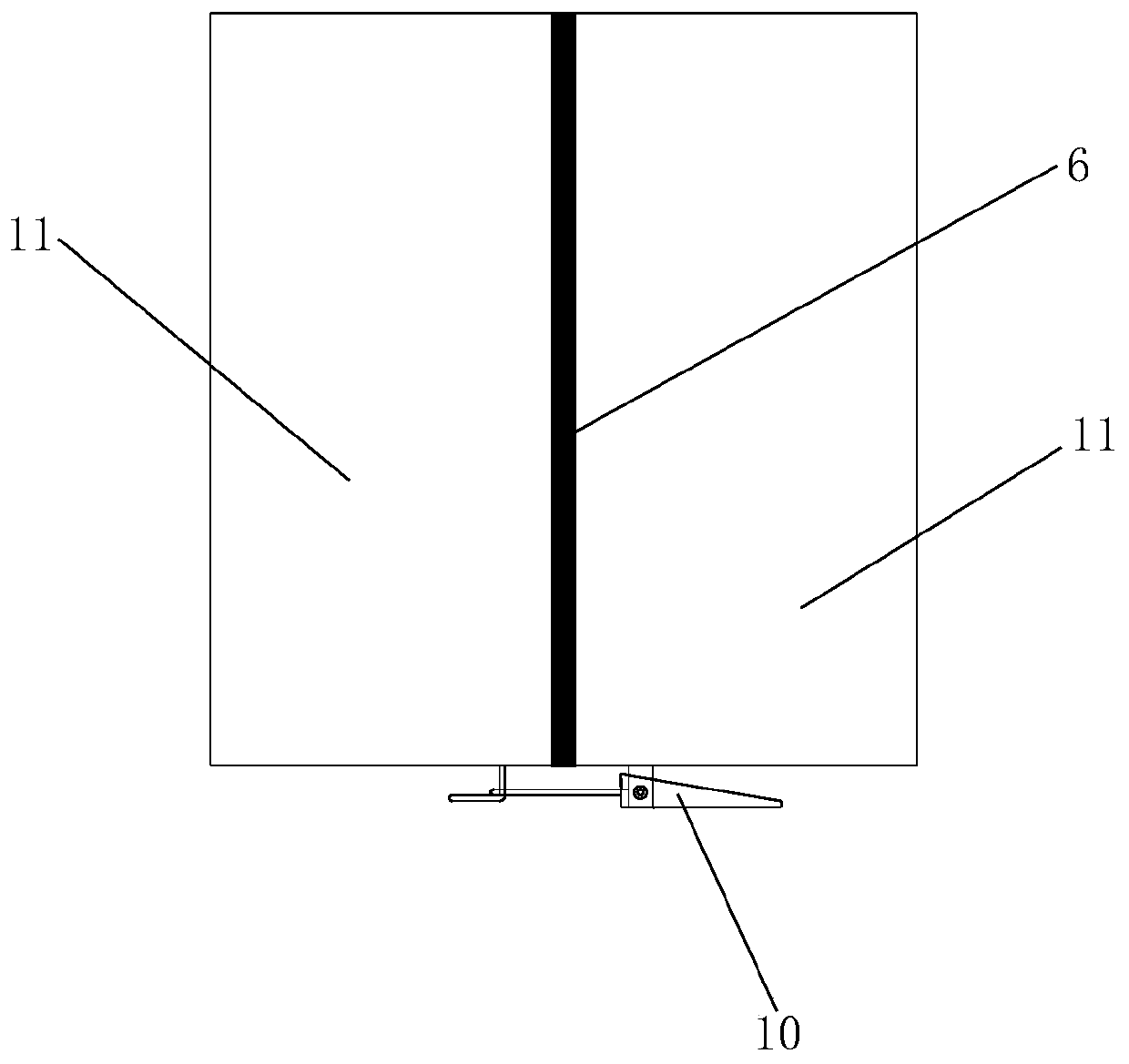

Intelligent energy-saving window for communication computer rooms and control method thereof

ActiveCN102493734AImprove insulation effectReduced insulation performancePower-operated mechanismWing arrangementsFire protectionElectric machine

This invention provides an intelligent energy-saving window for communication computer rooms, which comprises an energy-saving window body mounted on the inner side of the outer window of a communication computer room through a guide rail, wherein drive pulleys are arranged between the energy-saving window body and the guide rail; the drive pulleys are connected with a window body motor; the window body motor is connected with a background computer; the outer side of the outer window is provided with an outdoor temperature / humidity sensor connected with the background computer; the inner sideof the energy-saving window body is provided with an indoor temperature / humidity sensor; and the background computer controls the energy-saving window body to move through the window body motor and the drive pulleys in sequence. The invention also discloses a control method of the intelligent energy-saving window for communication computer rooms, which comprises the following steps of: inputting parameters; calculating an indoor average enthalpy and an outdoor average enthalpy; judging the value of the indoor average enthalpy and the outdoor average enthalpy, and controlling the energy-savingwindow to open and close according to the relationship between the indoor average enthalpy and the outdoor average enthalpy and the relationship between the difference of the indoor average enthalpy and the outdoor average enthalpy and the set parameters. The invention has the advantages of energy saving, intelligence, integration of fire protection, A-grade fireproof performance, convenient cleaning for outer window and no change of the appearance effect of building.

Owner:CHINA INFOMRAITON CONSULTING & DESIGNING INST CO LTD

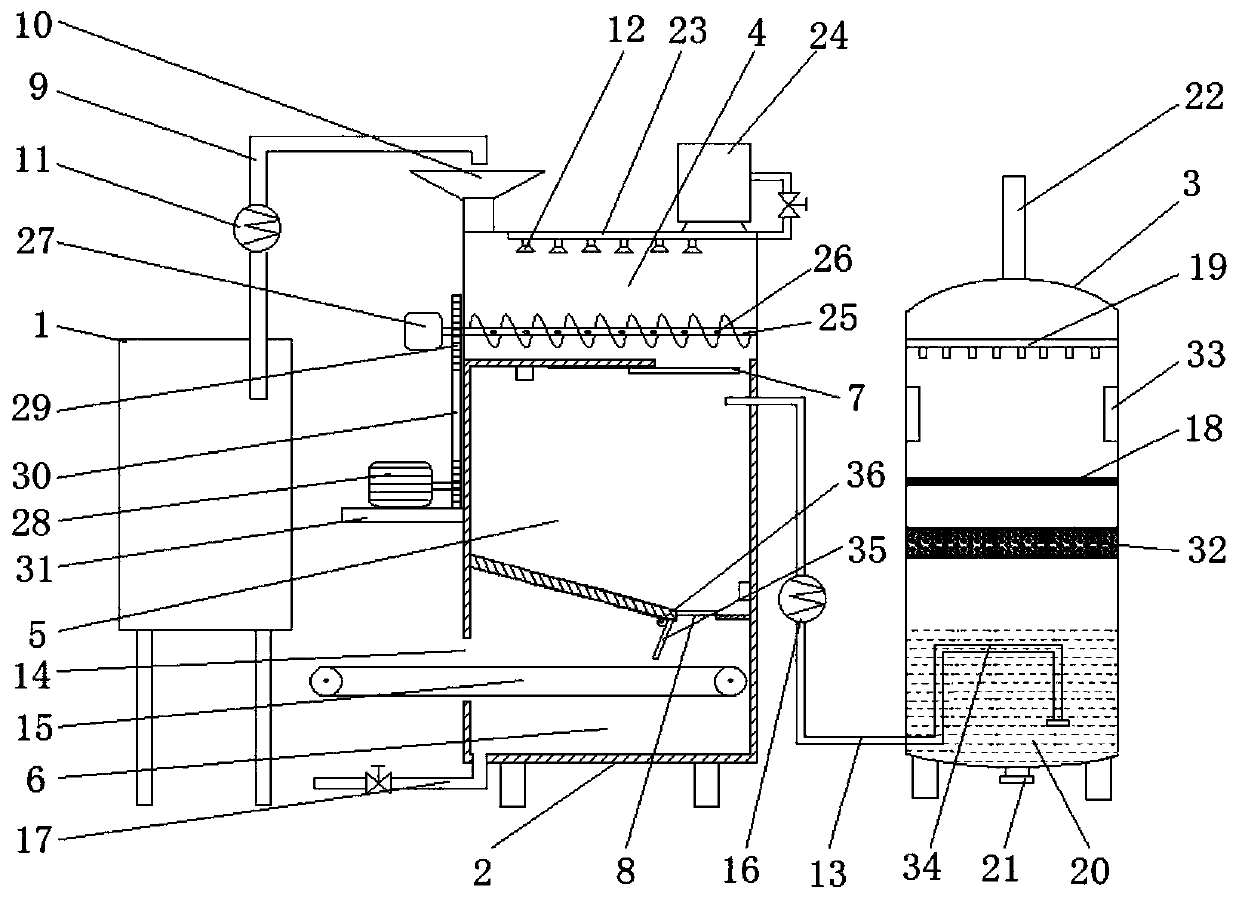

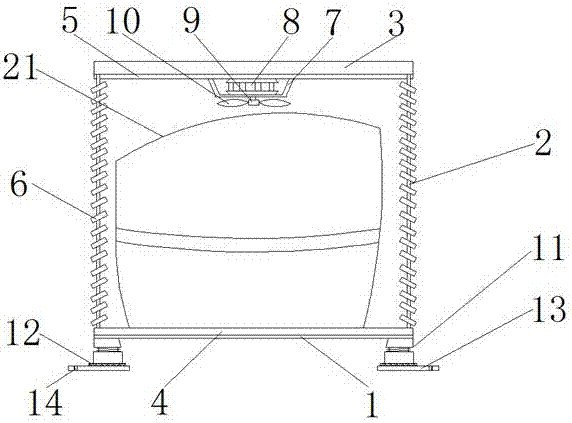

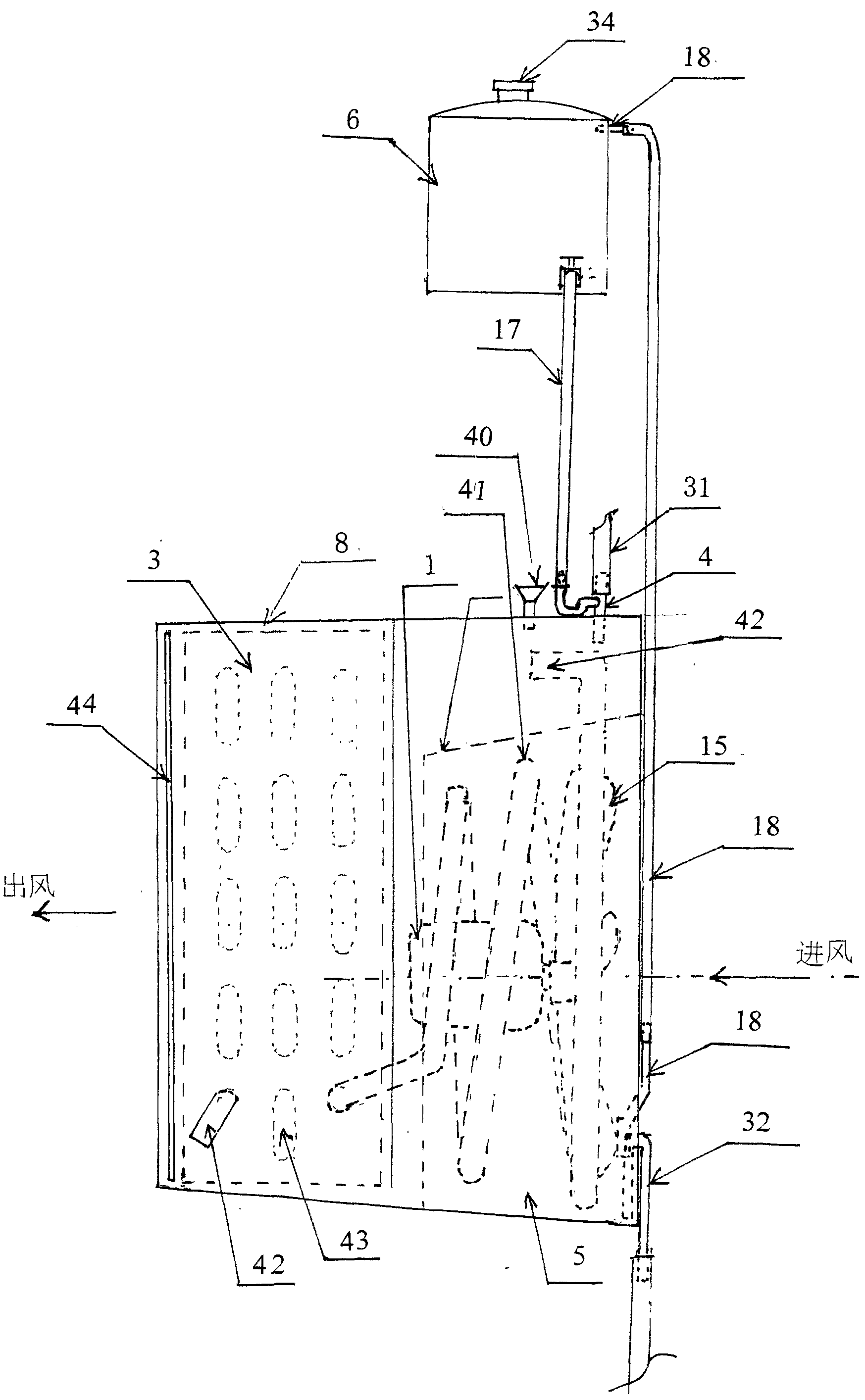

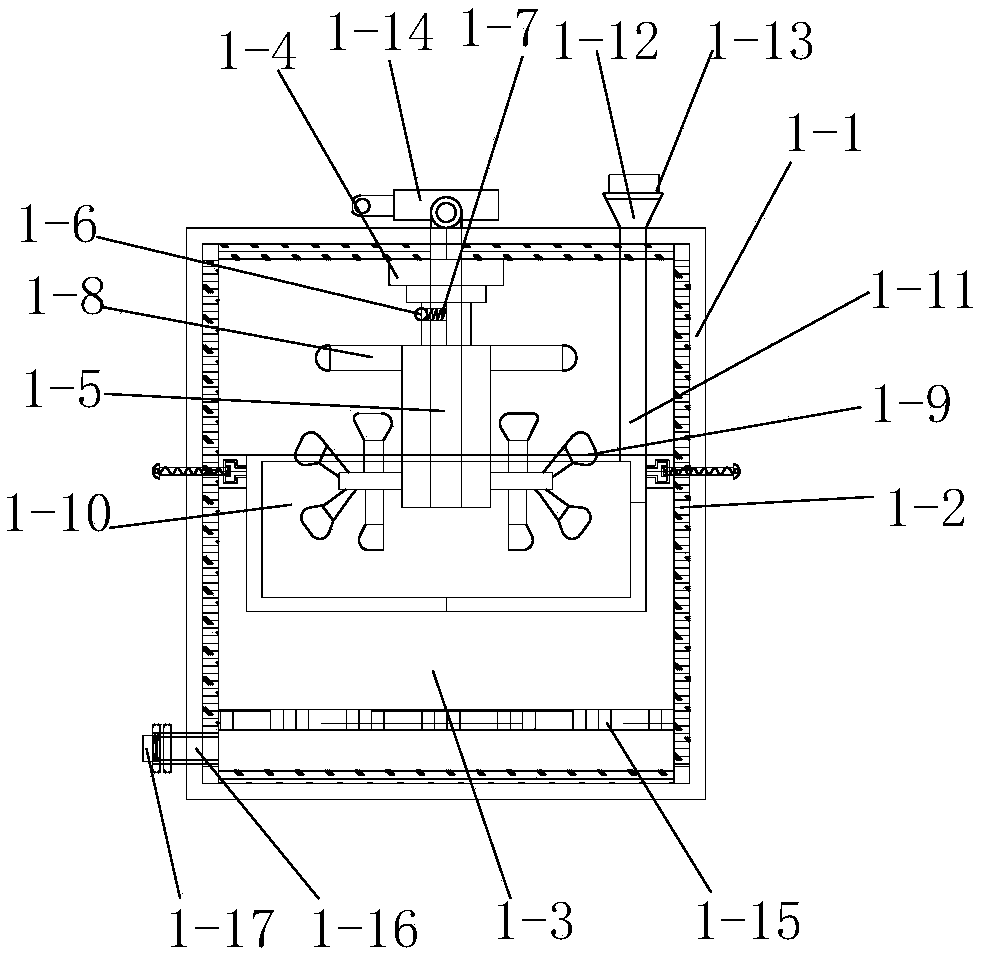

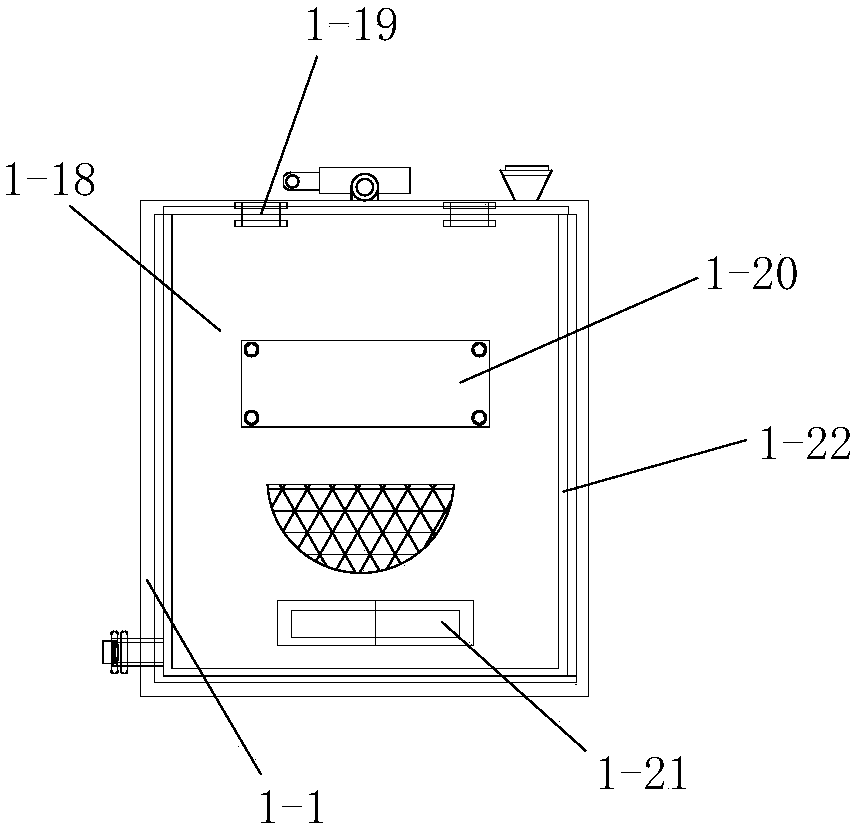

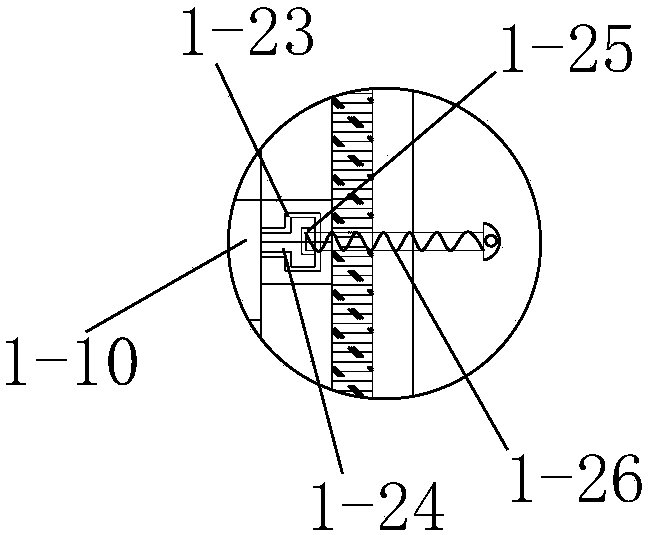

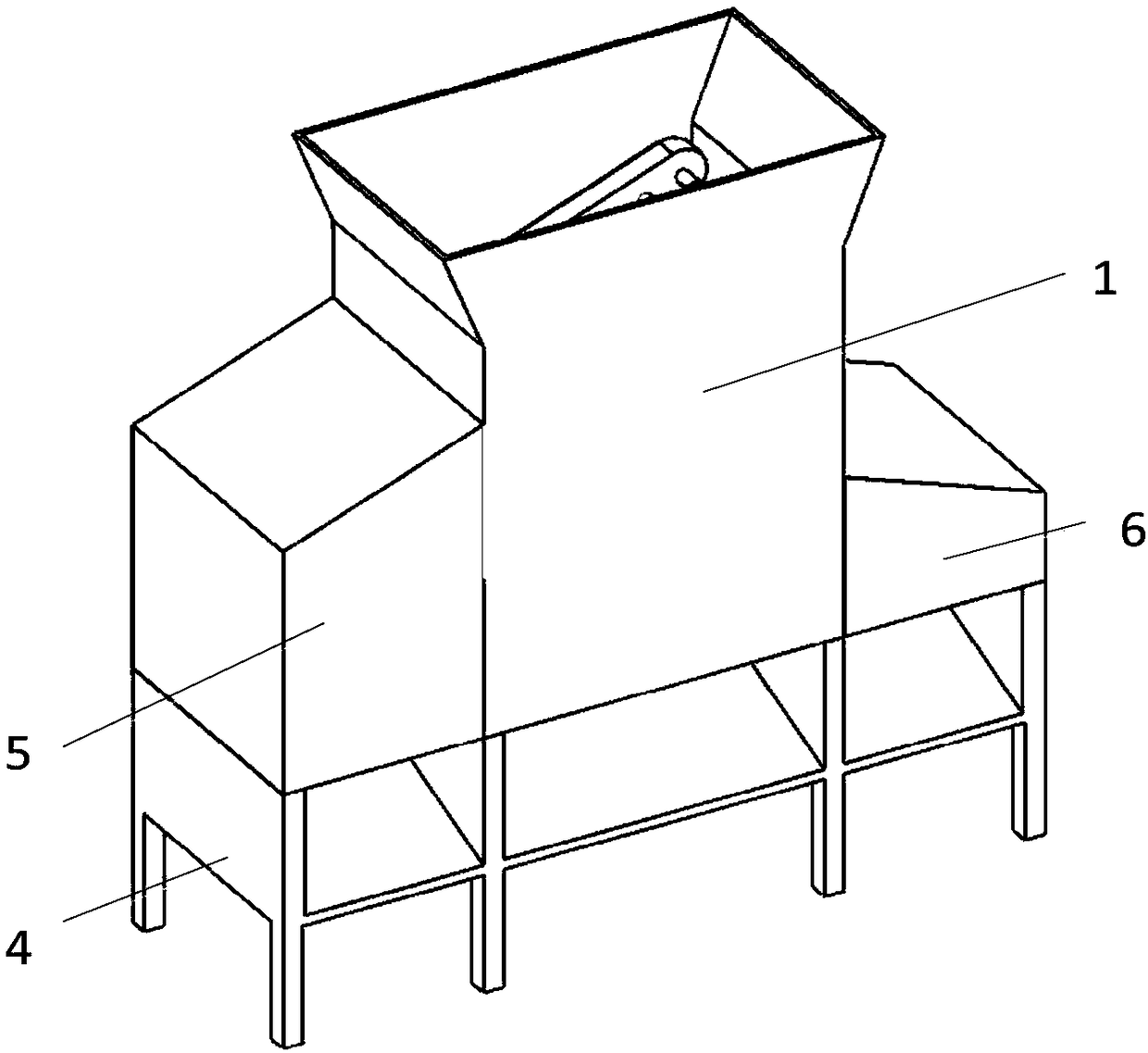

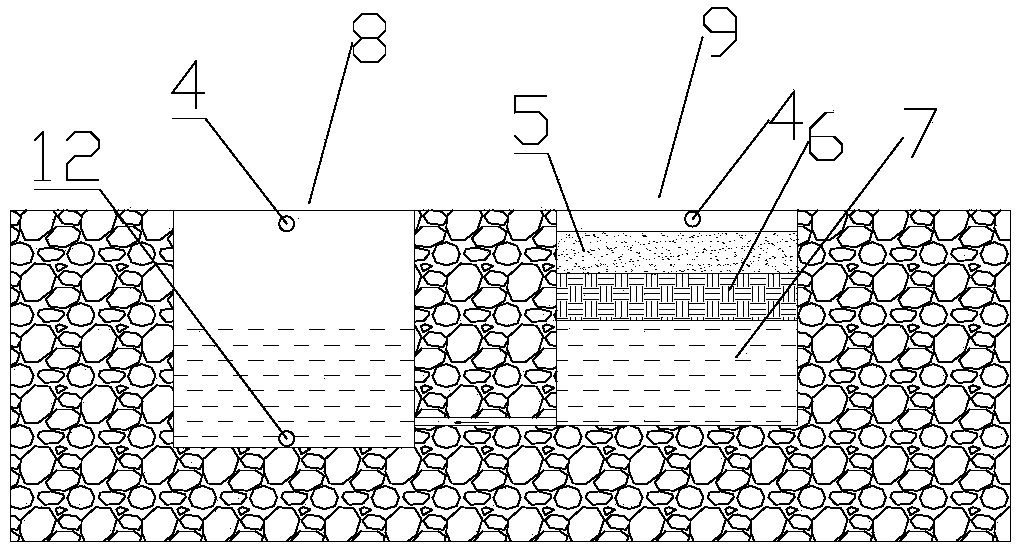

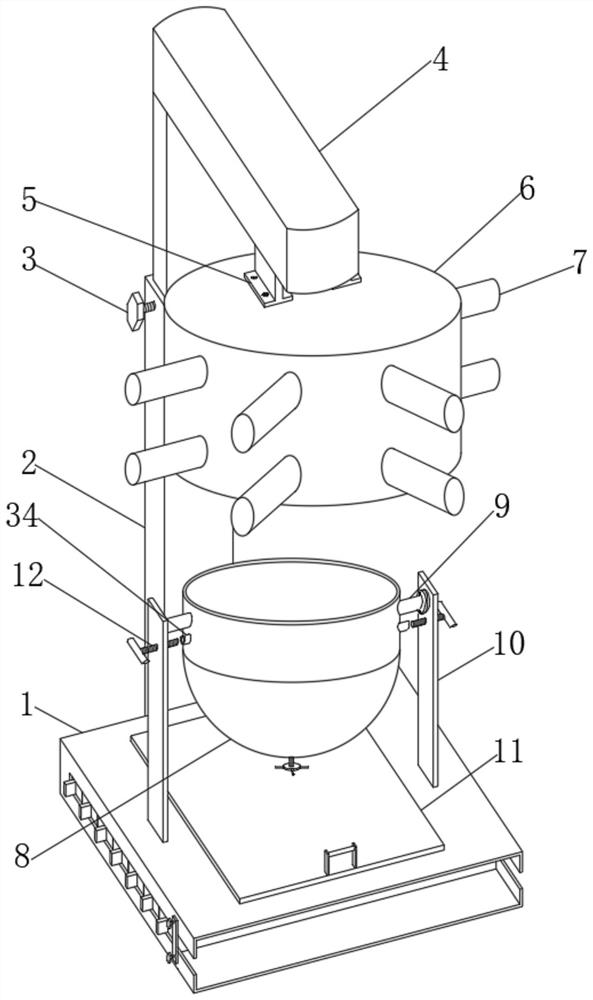

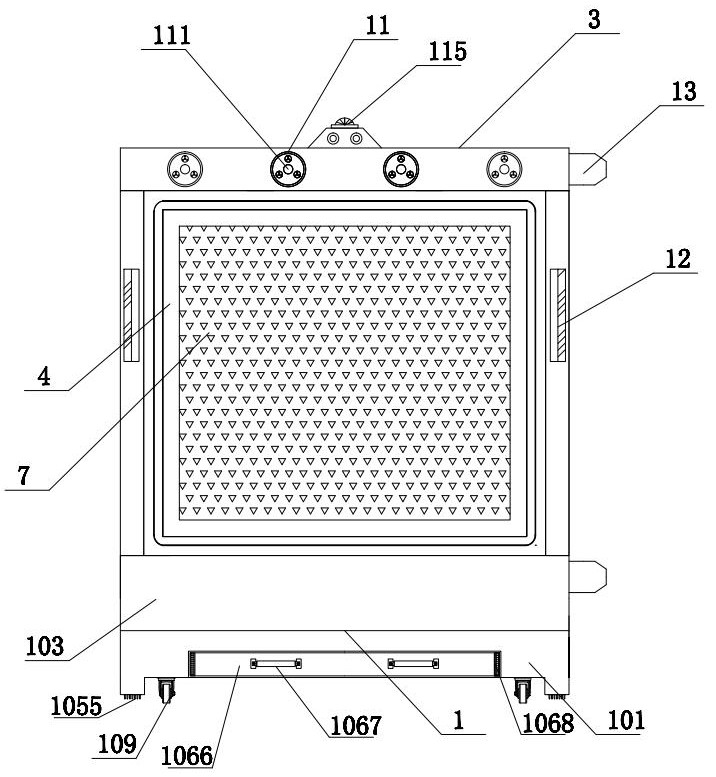

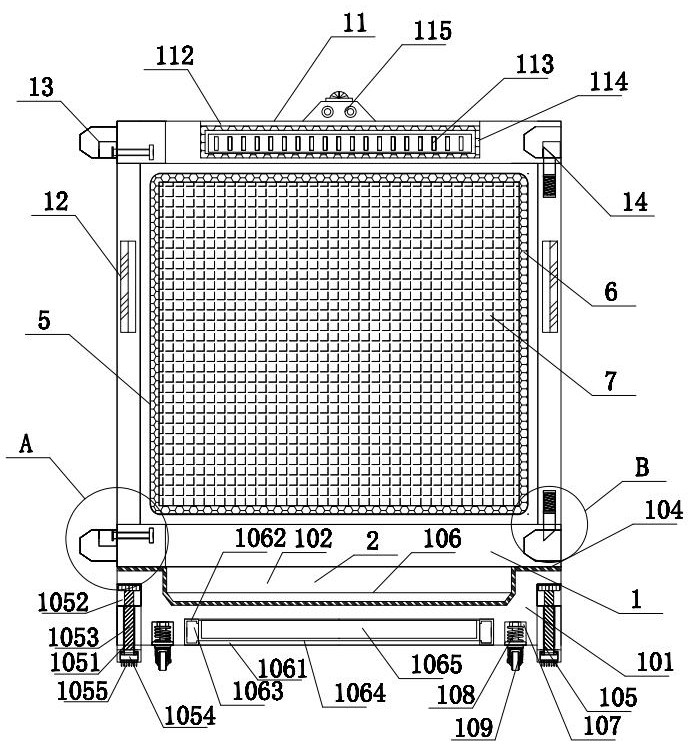

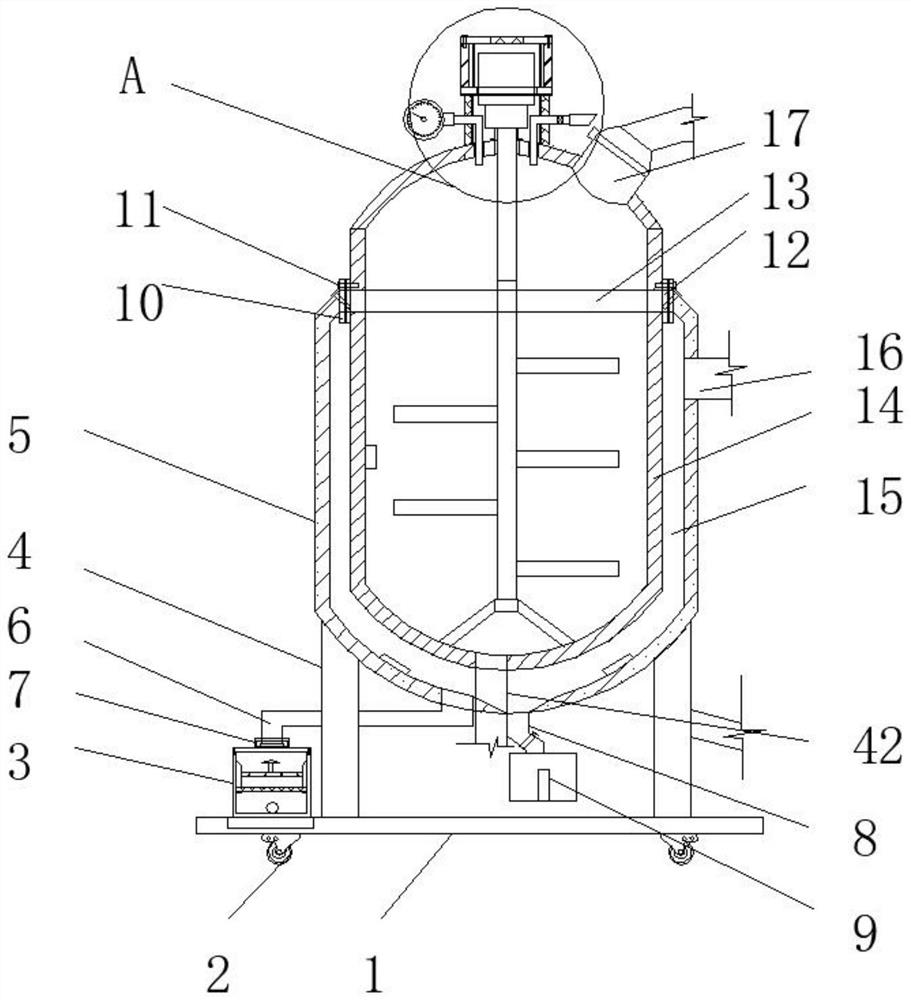

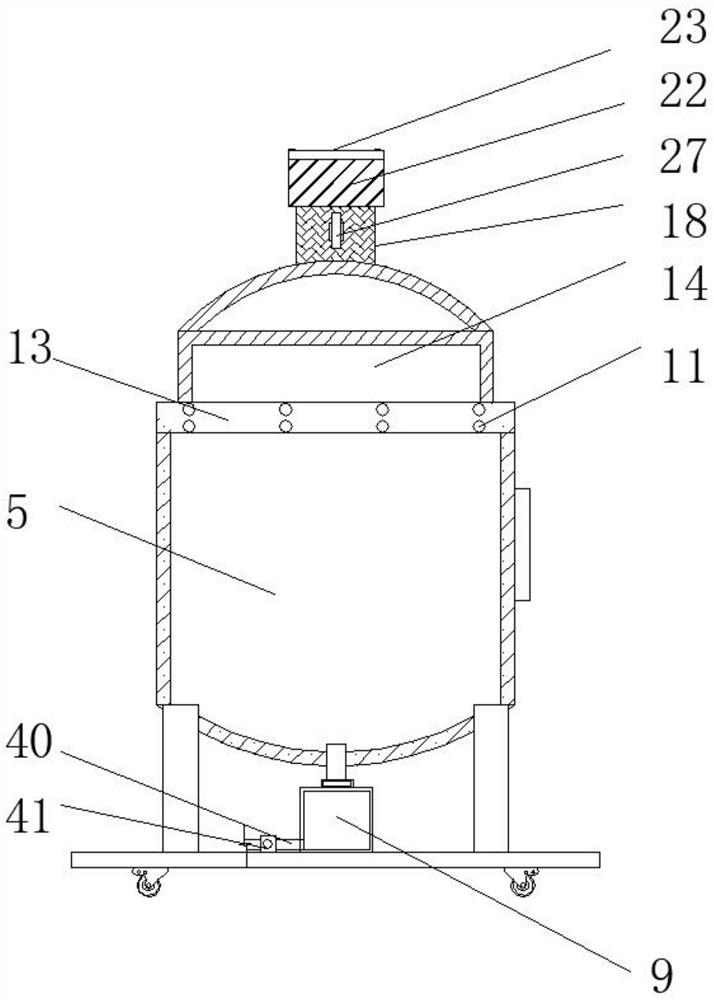

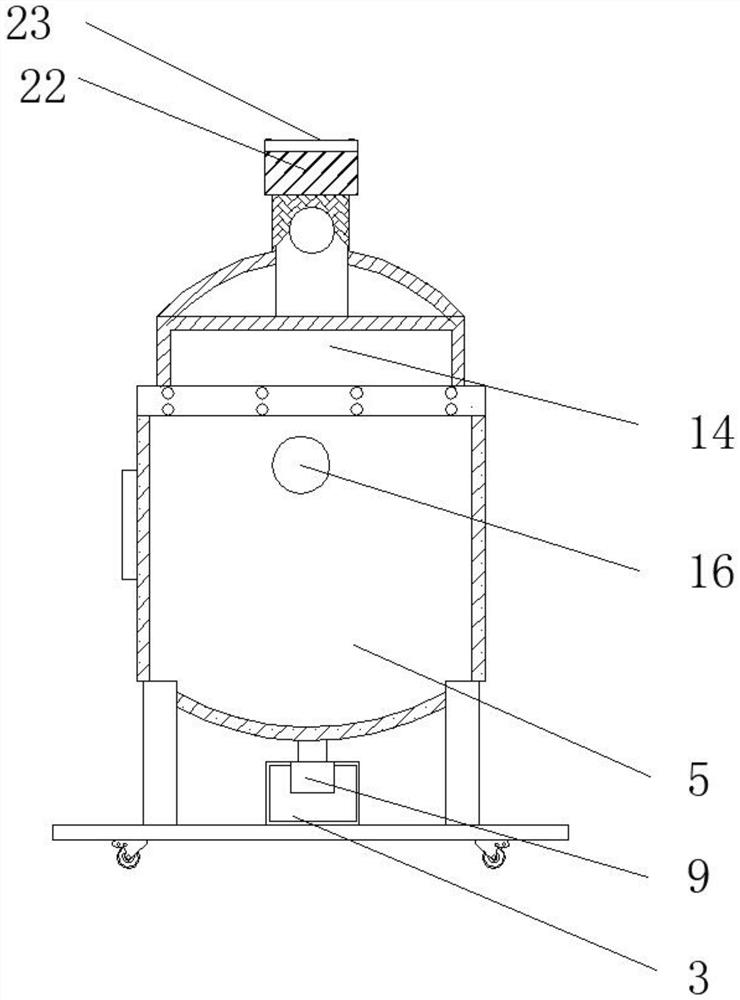

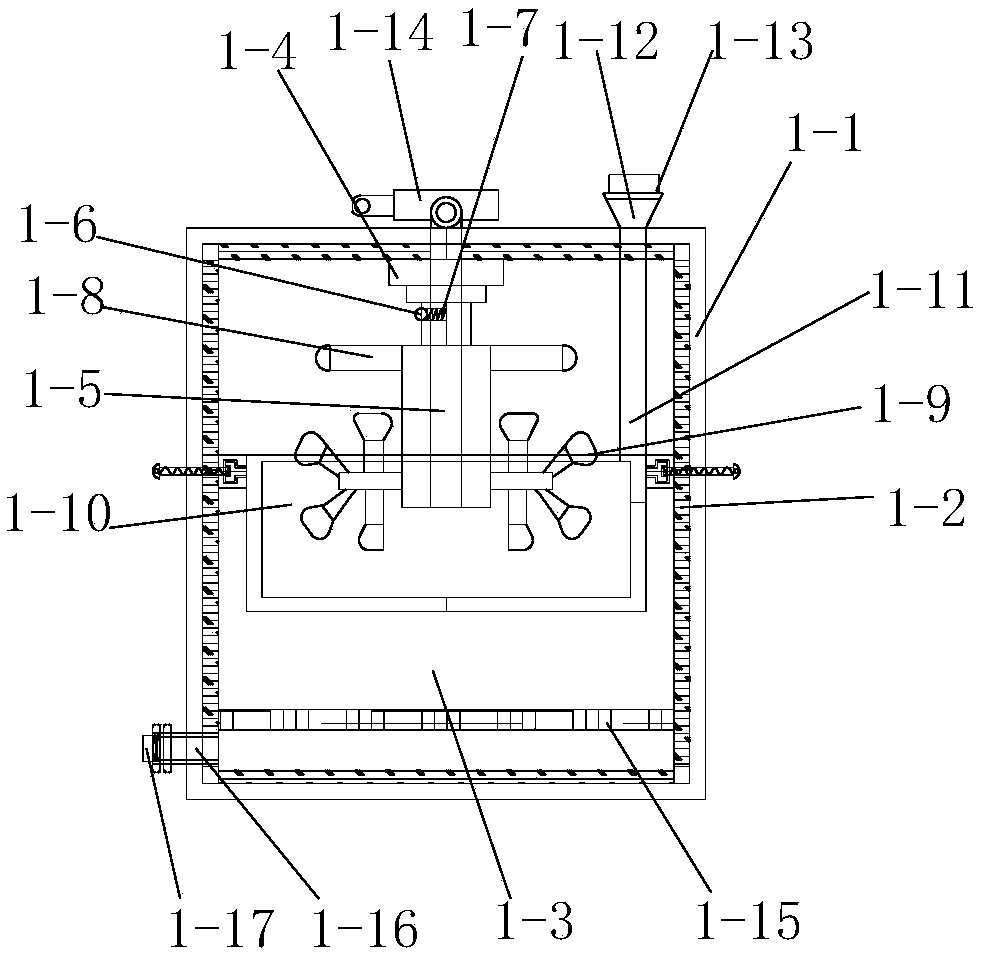

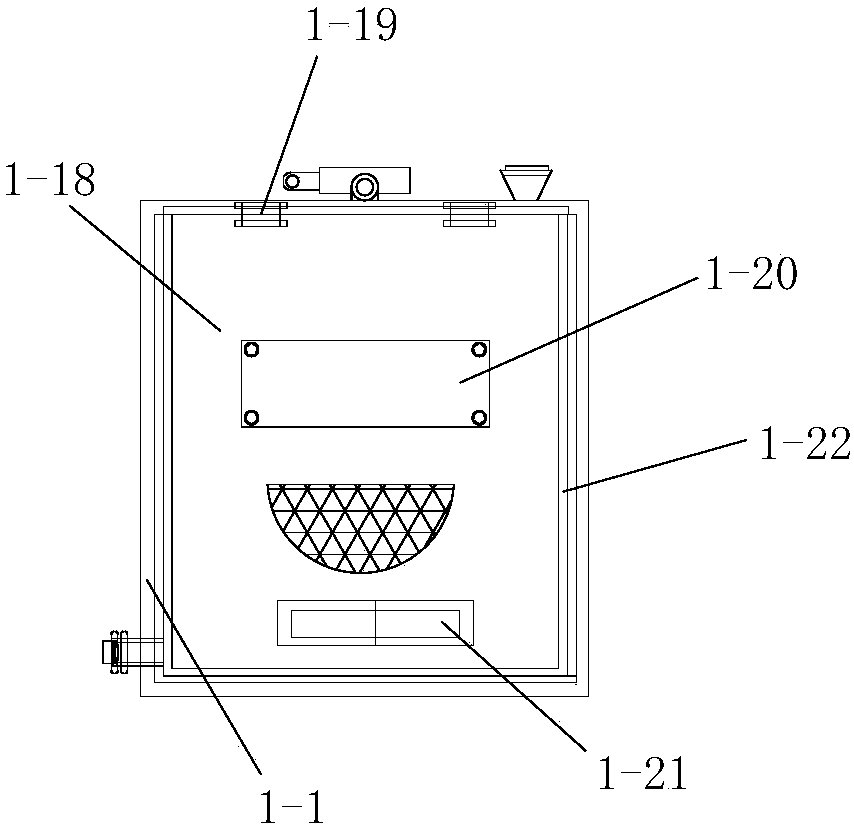

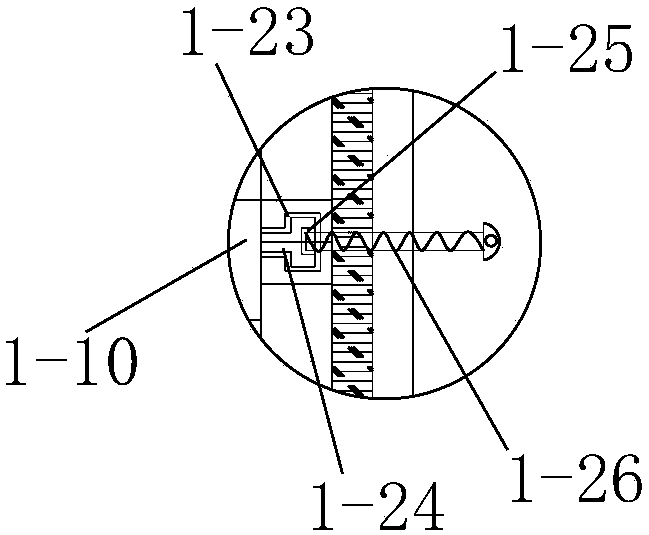

Livestock and poultry manure fermentation system

ActiveCN110577417AReduce outgoingAvoid pollutionClimate change adaptationExcrement fertilisersLivestockMixing chamber

The invention discloses a livestock and poultry manure fermentation system. The system comprises a manure storage tank, a fermentation tank and a deodorization tank, a mixing chamber, a fermentation chamber and a fermentation seepage collection chamber are arranged in the fermentation tank, a feed hopper is arranged above the mixing chamber, a material guide auger is arranged in the mixing chamber, the top surface of the mixing chamber is provided with strain liquid spray heads, a mesh conveying belt is arranged in the fermentation seepage collection chamber, a fermentation seepage collectingarea is arranged below the mesh conveying belt, a cleaning unit, a drying layer and an ultraviolet lamp are sequentially arranged in the deodorization tank along the flowing direction of a gas, and achemical liquid is contained in the cleaning unit. A strain liquid is sprayed while materials are fed into the mixing chamber through the feeding hopper, the manure and the strain liquid are evenly mixed under the action of the material guide auger, and then enter the fermentation chamber, and odorous gas generated during fermentation in the fermentation tank is discharged into the deodorization tank, is sequentially washed with the chemical liquid, dried with the drying layer and irradiate-disinfected with the ultraviolet lamp, and finally is discharged. The system has the advantages of simple structure, close, compact and efficiently and stably operated links, good harmful gas deodorizing, purifying and disinfecting functions, and high practicability.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

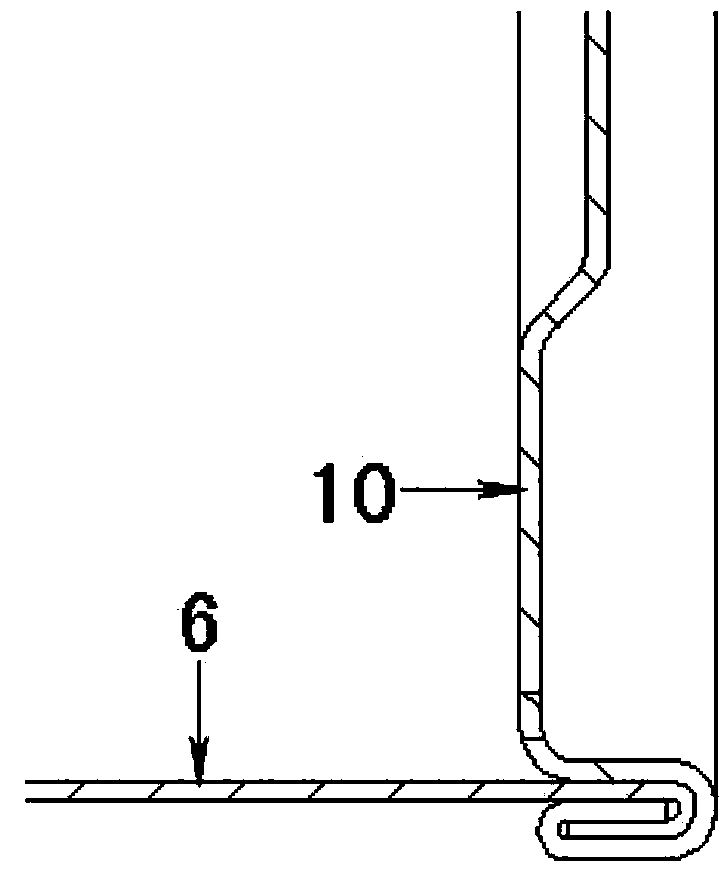

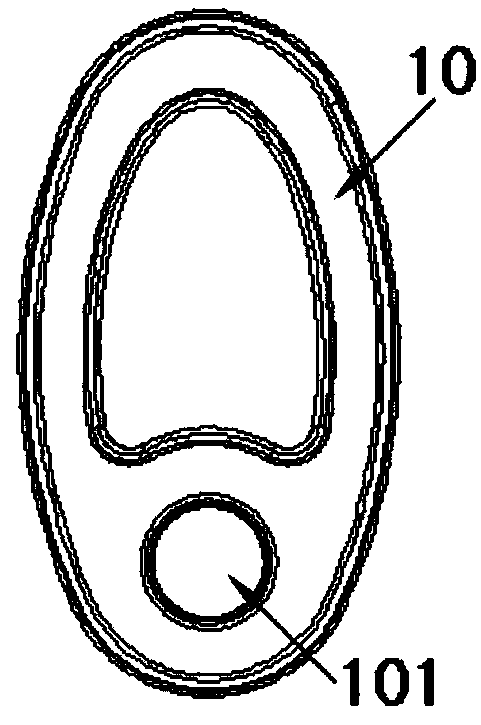

Noise reduction compressor applied to refrigerators

InactiveCN107989773AImprove shock absorptionReduce outgoingPositive displacement pump componentsPositive-displacement liquid enginesEngineeringNoise reduction

The invention provides a noise reduction compressor applied to refrigerators and relates to the technical field of compressors. The noise reduction compressor applied to the refrigerators comprises abottom plate, wherein vibration reducing legs are fixedly mounted at the bottom of the bottom plate; the bottom of each vibration reducing leg adheres to the top of a rubber foot pad; the bottom of each rubber foot pad adheres to the top of a fixed plate; a PVC transparent plastic plate adheres to the top of the bottom plate; a compressor body is fixedly mounted at the top of the PVC transparent plastic plate; and a top plate is arranged at the top of the compressor body. According to the noise reduction compressor applied to the refrigerators, the vibration reducing legs and the rubber foot pads are arranged, so that the vibration generated during operation of the compressor body is buffered and reduced; the strength of the vibration transmitted to the bottom contact surface of the compressor is reduced; the noise is reduced; meanwhile, a rubber layer, oblique plates sleeved with aluminum foil glass wool and the PVC transparent plastic plate are arranged on the periphery of the compressor body; the noise generated during operation of the compressor body is absorbed and isolated; and the transmission of the noise is reduced and weakened.

Owner:岳文智

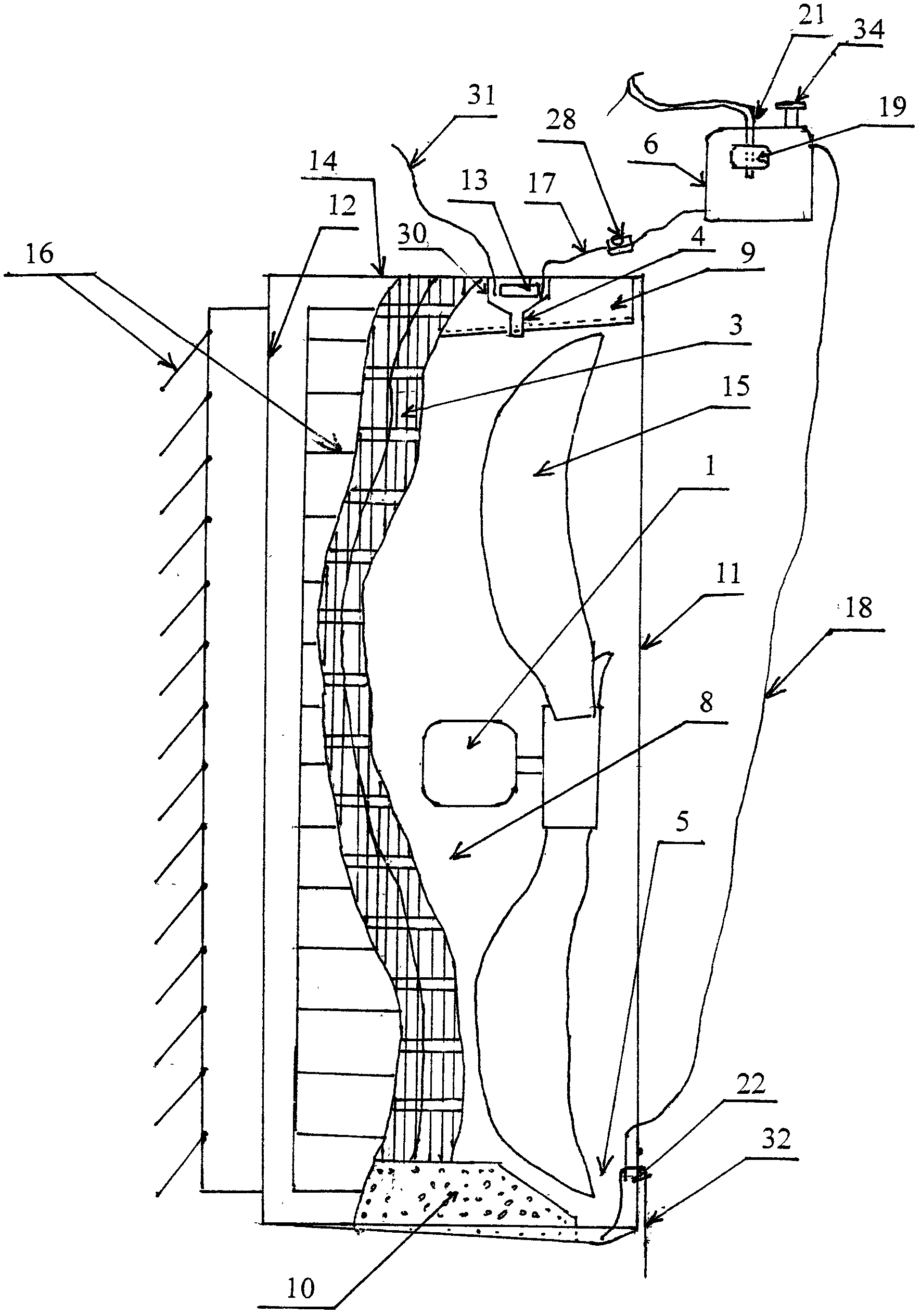

Splashing and air cooling combined condenser room with anti-frosting fan blades

InactiveCN102494368AReduce the temperatureIncrease energy consumption or even burnEnergy recovery in ventilation and heatingLighting and heating apparatusSmall dropletEvaporation

The invention relates to a splashing and air cooling combined condenser room with anti-frosting fan blades. Small droplets are splashed by the rotating fan blades by means of dripping water on the rotating fan blades and soaking the lower end points of the rotating fan blades to splash water, and the splashed small droplets are adhered to radiation fins of a condenser to evaporate and absorb heat, so that the temperature of a refrigeration fluid is reduced and the energy consumption is reduced in a condition that the heat of the condenser of an air conditioner is radiated in a combined evaporation and air cooling manner. By changing a power supply connection manner of a blower capacitor, a blower generates flowing air in different flowing directions according to different rotating directions of refrigeration or heating. The flowing air takes away the heat of a compressor in the refrigeration process and is blown out from the condenser room. When the air conditioner heats, the heat of the compressor is absorbed and transmitted to fins of the condenser (an evaporator) by the flowing air so that the fins are prevented from being frosted.

Owner:骆金山

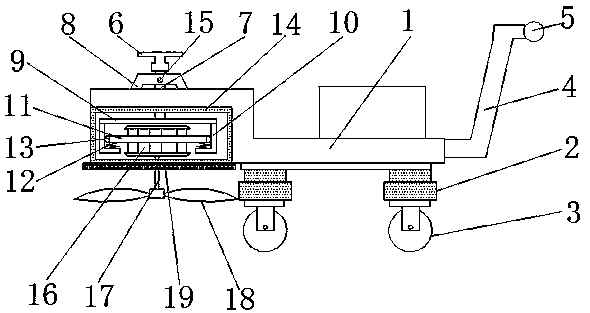

Lawnmower with noise reduction function

InactiveCN108207283AWith noise reduction functionImprove shock absorptionMowersRubber ringEngineering

The invention provides a lawnmower with a noise reduction function, and relates to the technical field of lawnmowers. The lawnmower with the noise reduction function comprises a base, wherein the bottom of the base is fixedly provided with a fixing plate, the bottom of the fixing plate is fixedly provided with damping legs, the bottoms of the fixing legs are fixedly provided with universal wheels,one side of the base is fixedly provided with a fulcrum bar, and the top of the fulcrum bar is fixedly provided with a handle. According to the lawnmower with the noise reduction function, a frame plate is arranged to support the lawnmower overhead, the frame plate is put up through a damping spring, the side wall of the frame plate is provided with a rubber ring, the rubber ring is in contact with side plates, so that the lawnmower is more stable, the damping spring and the rubber ring have a good damping effect, can buffer vibration, the vibration can be transferred to other parts through amotor, thus the noise emission is effectively reduced, a sound proof box is arranged to isolate and absorb the noise generated by the motor, an acoustic panel is arranged to absorb the noise generated by cutting blades, and thereby the effect of the noise on surroundings when mowing is effectively reduced.

Owner:佛山市倍尚利环保科技有限公司

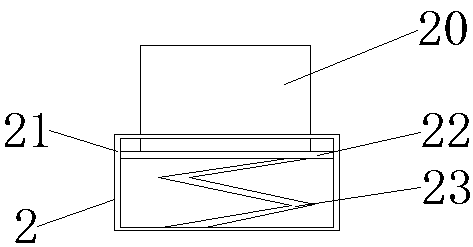

Road and bridge construction surface spraying device and spraying method thereof

InactiveCN108787220ASpeed up the drying processSpray evenlySpray nozzlesPretreated surfacesEngineeringBolt connection

The invention discloses a road and bridge construction surface spraying device. The road and bridge construction surface spraying device comprises a storage box for loading paint, a remote control vehicle for loading the storage box, a discharge cavity and a control device, wherein the control device is connected with the remote control vehicle in a bolted mode; the storage box is located above the remote control car, and the remote control vehicle is provided with a groove; the storage box is placed in the groove, and the storage box is fixedly connected with the groove; the storage box is detachably connected with the remote control vehicle through the groove, a material pumping pump is arranged on the right side of the storage box, and feed delivery pipes are connected to a feeding portand a discharging port of the material pumping pump; the feeding port and the discharging port of the material pumping pump are all connected with the corresponding feed delivery pipes on the feedingport and the discharging port in a bolted mode, the feed delivery pipes communicate with the discharge cavity, the feed delivery pipes are connected to the discharge cavity in a bolted mode, and thedischarge cavity is connected with a spraying pipe; and the spraying pipe is connected with the discharge cavity in a bolted mode, and the spraying pipe is provided with a spraying pump. The road andbridge construction surface spraying device can effectively spray uniformly.

Owner:芜湖薰衣草知识产权运营有限公司

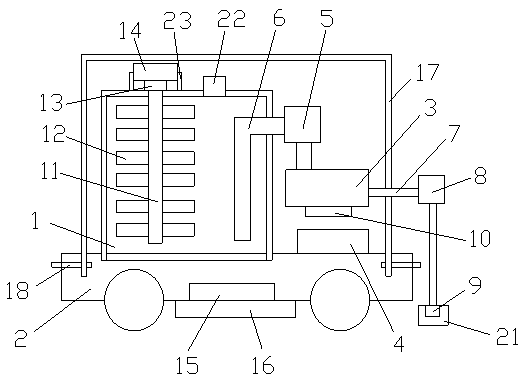

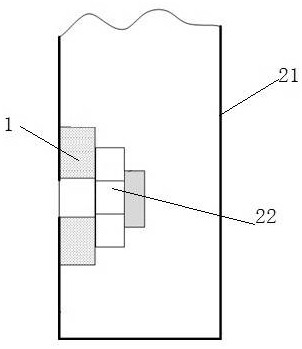

Aluminum-plastic sign polishing machining device

InactiveCN107953168AReduce outgoingImprove work efficiencyGrinding work supportsPlane surface grinding machinesRubber ringElectro hydraulic

The invention provides an aluminum-plastic sign polishing machining device, and relates to the technical field of aluminum-plastic sign machining. The aluminum-plastic sign polishing machining devicecomprises a base, wherein foot pads are fixedly arranged at the bottom of the base; and the top of the base is welded to the bottom of an electro-hydraulic push rod, the top of the electro-hydraulic push rod is welded to the bottom of a top plate, and a motor is arranged at the bottom of the top plate. According to the aluminum-plastic sign polishing machining device, the motor is erected throughdamping springs, the vibration generated by the fact that the motor drives a polishing block to polish an aluminum-plastic sign through a rotating rod is buffered, less vibration is transmitted to theerection surface, the spreading of the noise is effectively reduced, meanwhile, a rubber ring is arranged to be in contact with a fixing plate so that the motor can be erected more stably, a sound insulation box sleeves outside the motor, the vibration generated during working of the motor is absorbed and isolated, so that spreading of the noise of the device is effectively reduced, the influenceof the working noise on the working personnel is reduced, and the working efficiency can be improved.

Owner:江苏新亚彩印包装有限公司

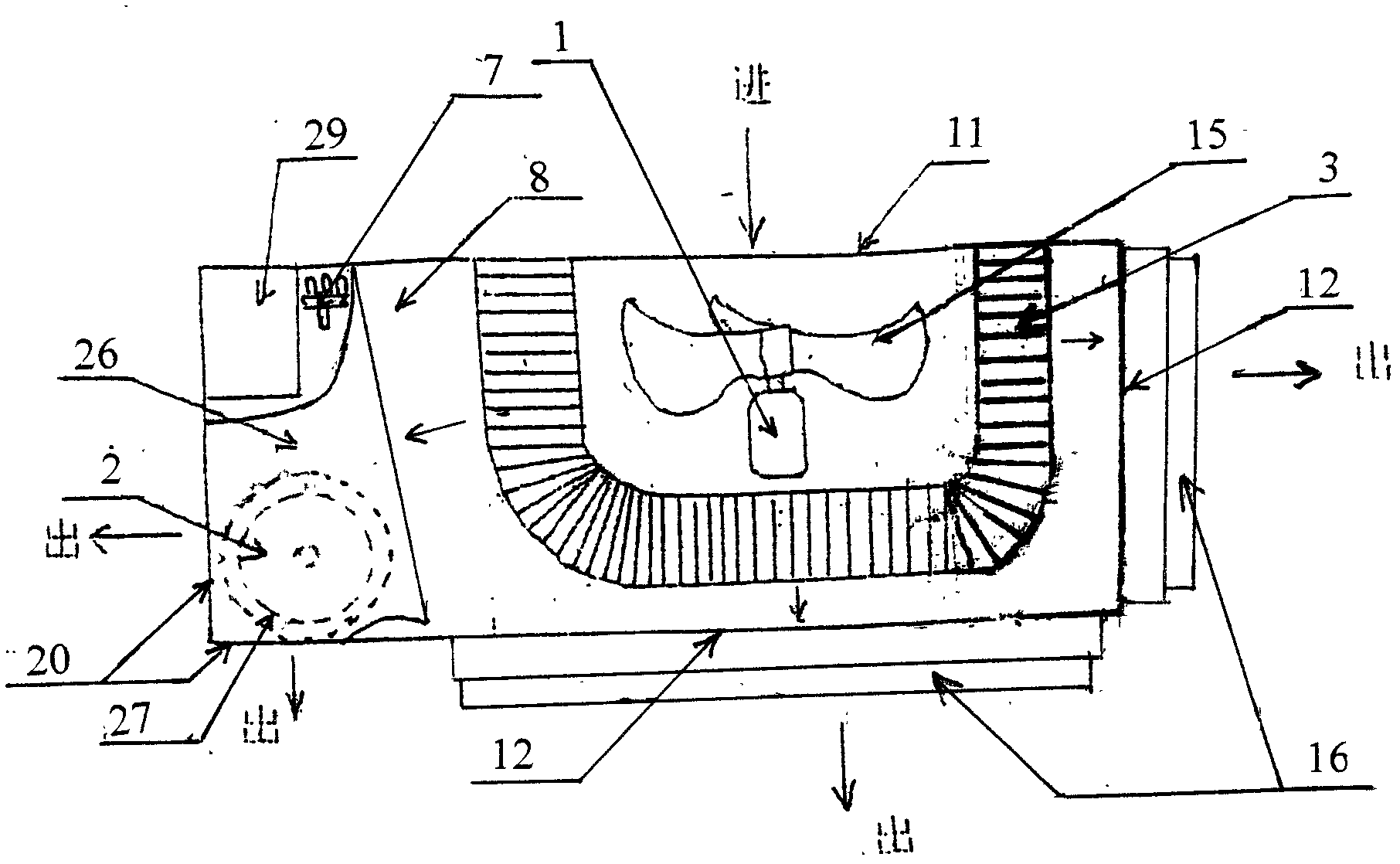

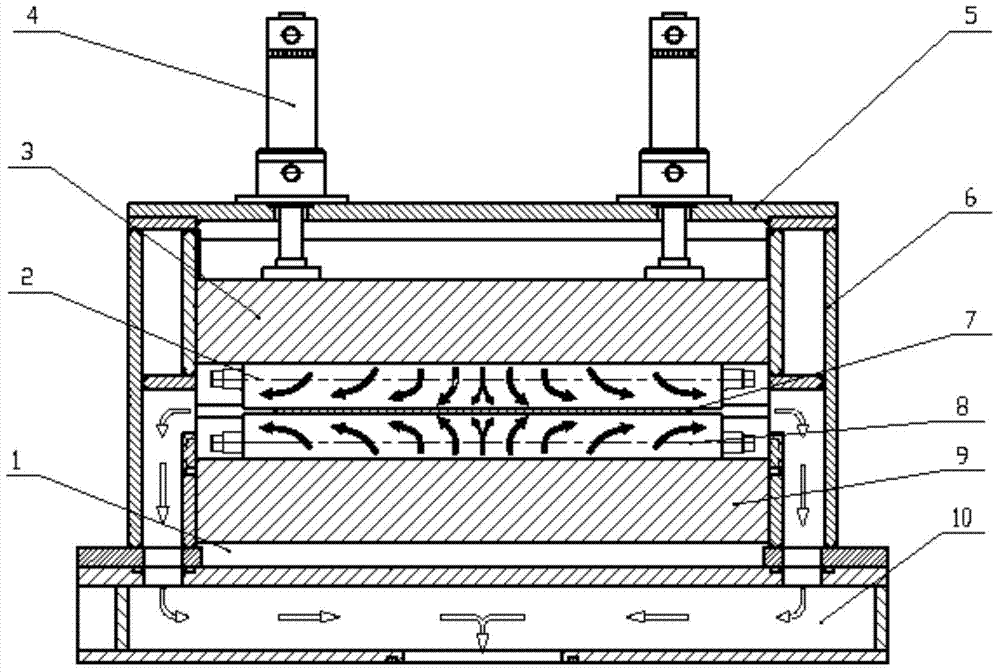

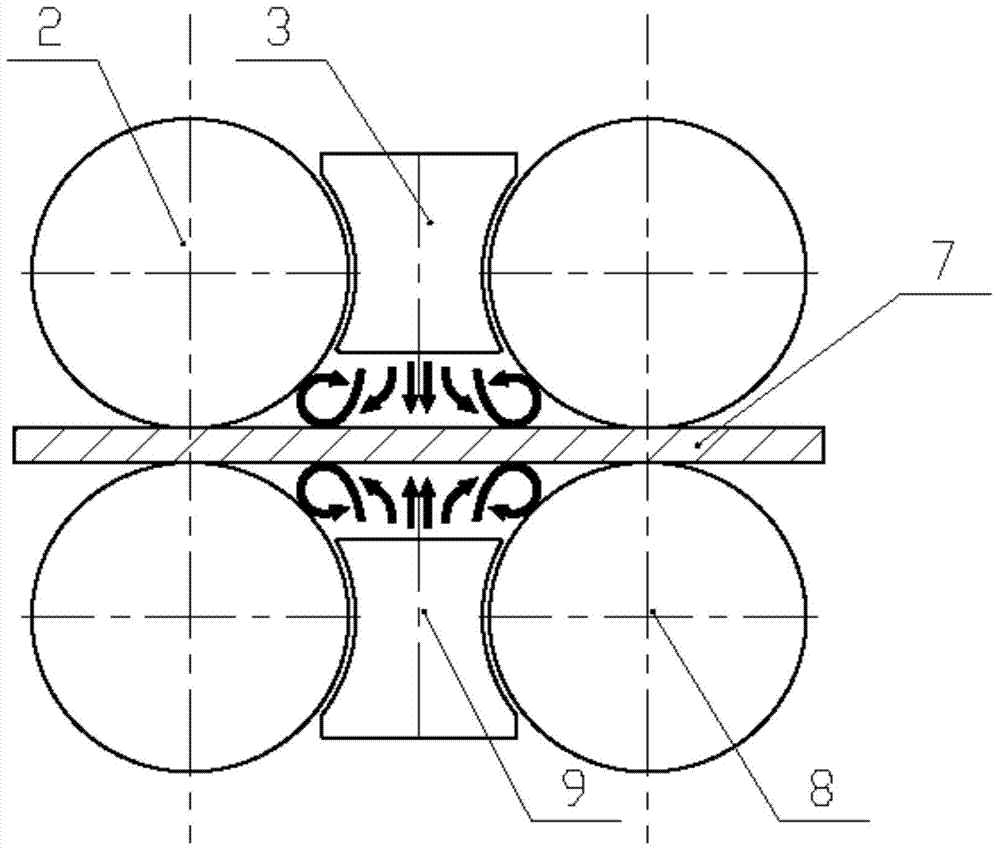

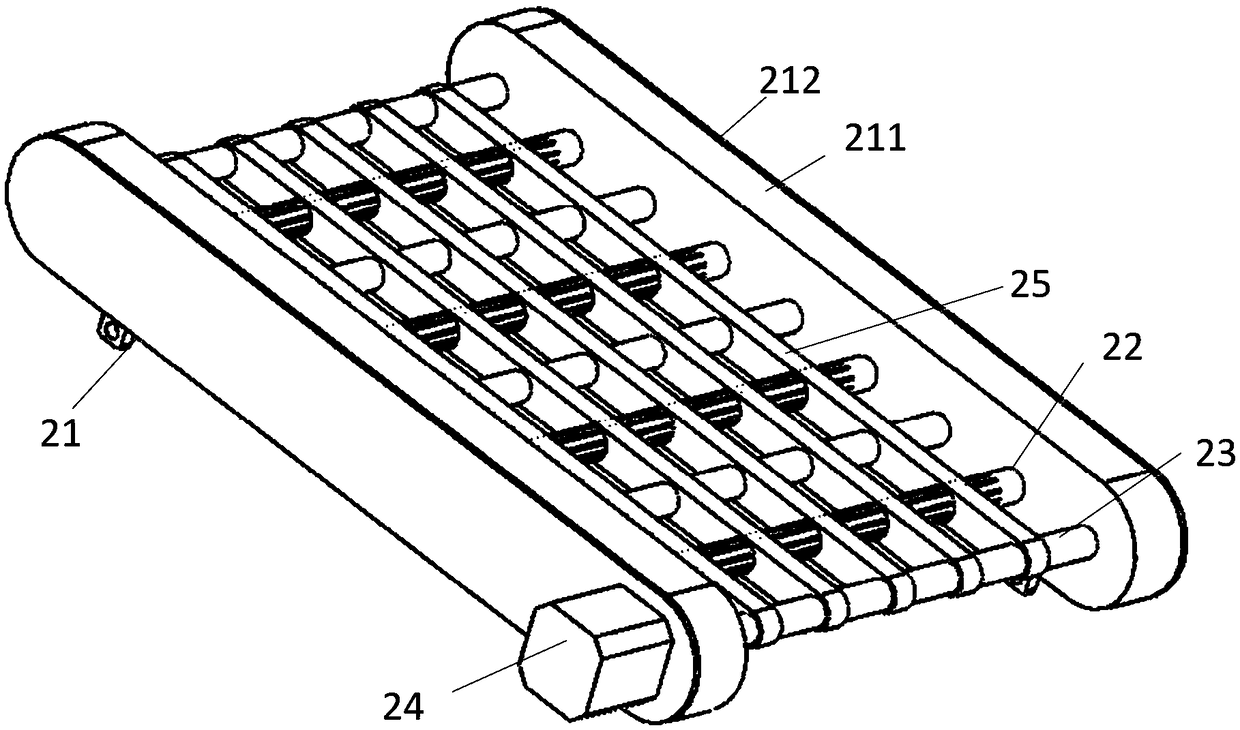

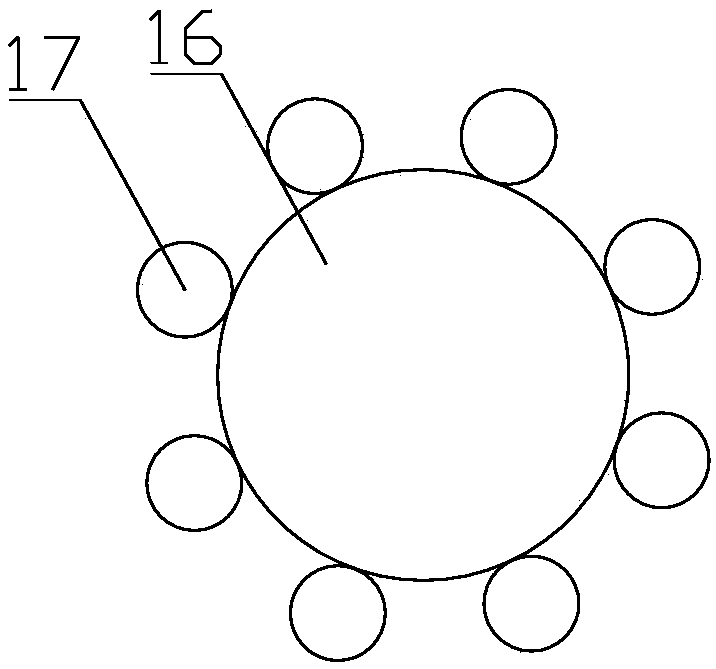

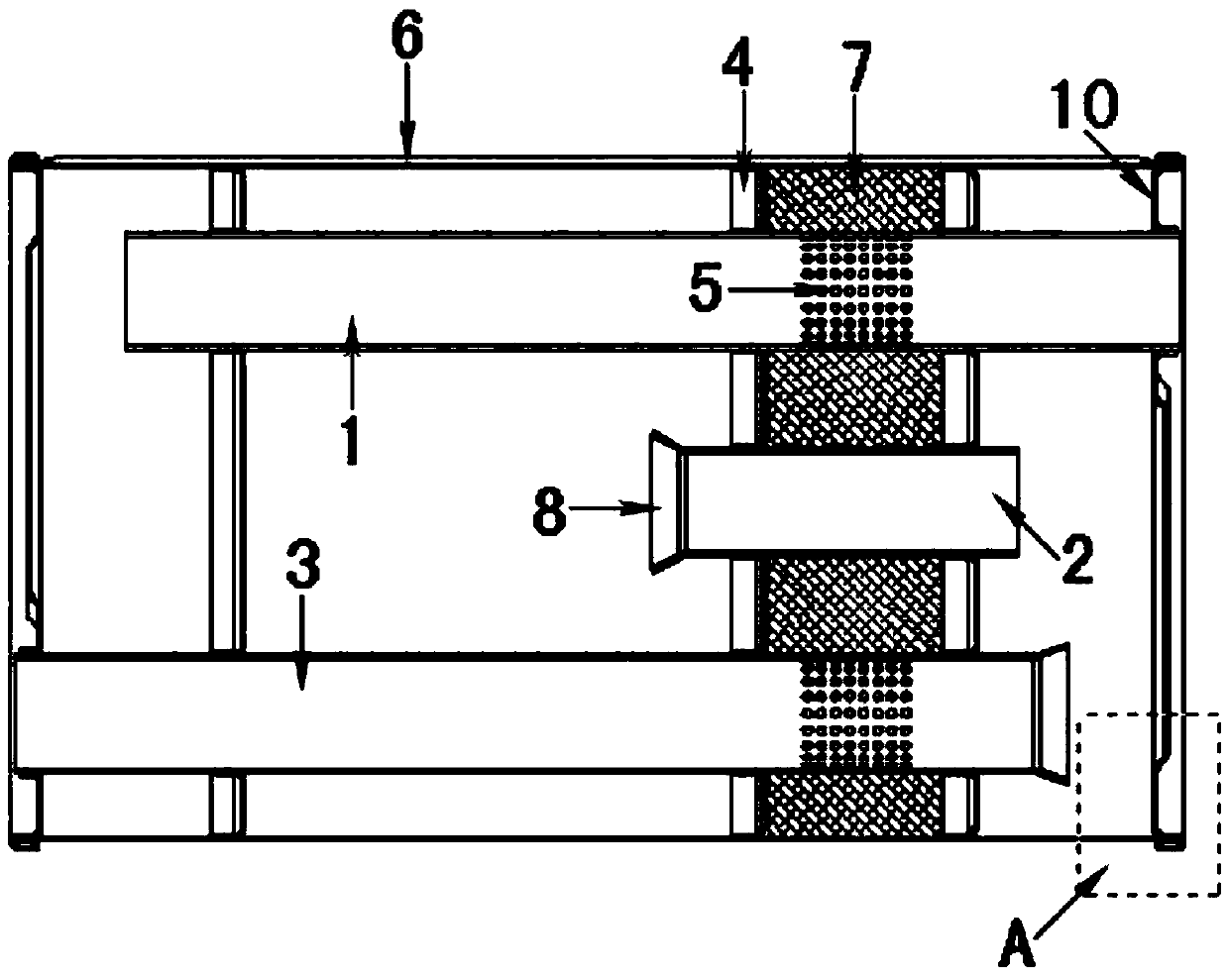

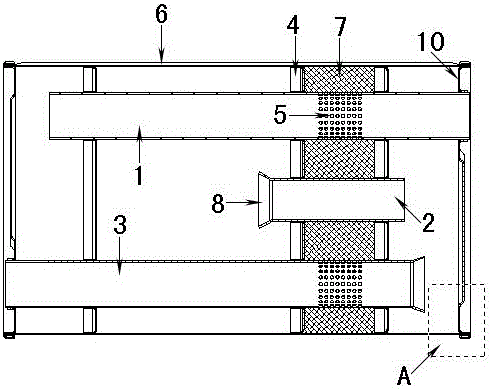

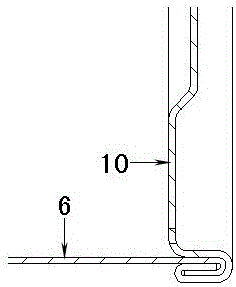

Multi-roll oil removal machine with built-in blowing and suction devices and strip oil removal method

ActiveCN104275354AReduce consumptionWon't spreadWork treatment devicesMetal rolling arrangementsEngineeringHigh pressure

The invention provides a multi-roll oil removal machine with built-in blowing and suction devices. The multi-roll oil removal machine comprises a rack, a plurality of oil removal rolls, blowing devices and a suction device, wherein the oil removal rolls are arranged in the rack and are arranged above and below a strip respectively; the blowing devices are arranged between upper oil removal rolls as well as between lower oil removal rolls; the upper and lower oil removal rolls are contacted with the strip to form a closed cavity which is defined by the strip, the oil removal rolls, the blowing devices and the rack; the blowing devices are communicated with the closed cavity; the suction device is communicated with the closed cavity through a passage. The noise and the pollution can be reduced and the technological lubricating oil can be saved during work. The invention also provides a strip oil removal method. The closed cavity is formed by making the upper and lower oil removal rolls in contact with the strip ; the blowing devices are arranged in the closed cavity to blow liquid remained on the surface of the strip through high-pressure low-flow compressed air to form fog; the suction device is used for sucking the fog from the two ends of the closed cavity in the axial direction of the oil removal rolls in a low-pressure high-flow mode to achieve an oil removal purpose.

Owner:北京斯蒂尔罗林科技发展有限公司

Cultivating method of ornamental bamboo seedlings

The invention discloses a cultivating method of ornamental bamboo seedlings. The cultivating method comprises the following steps: (A) pretreating seeds; (B) preparing a medium; (C) leveling a seedling bed; (D) carrying out seeding and soil covering; (E) carrying out nursery management; (F) transplanting bamboo seedlings; and (G) nourishing, managing and protecting the bamboo seedlings. Through the adoption of the method, the bamboo seedlings can be cultivated on a large scale by using bamboo seeds, and the germination rate and the transplanting survival rate are both high.

Owner:XINYANG AGRI & FORESTRY UNIV

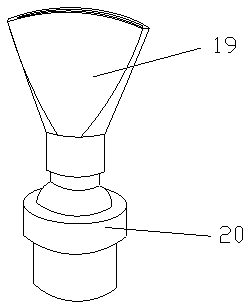

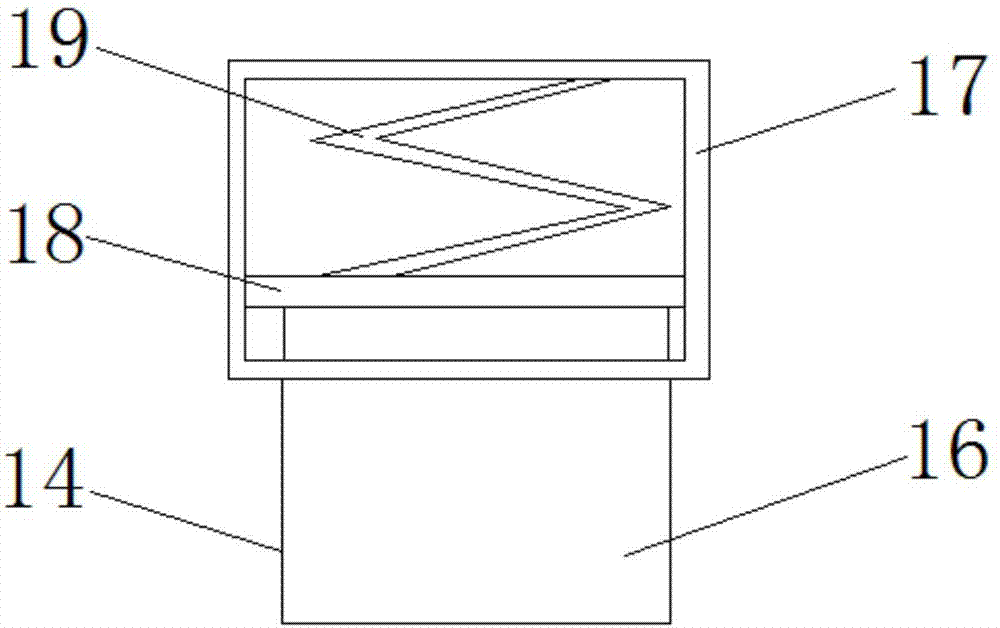

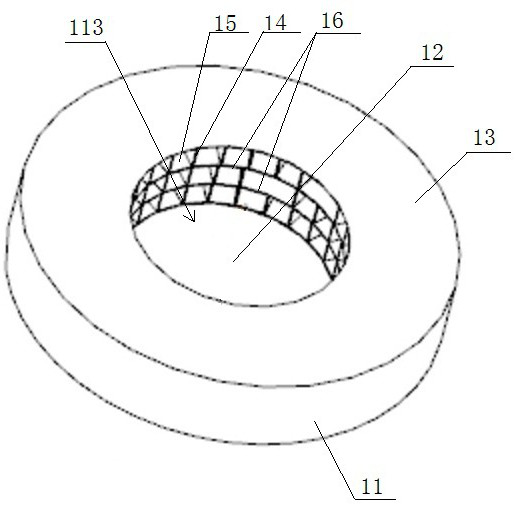

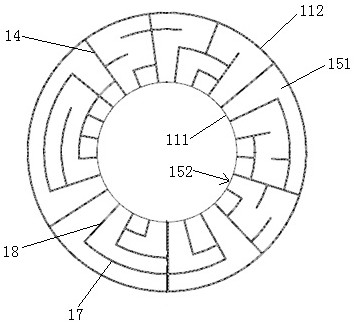

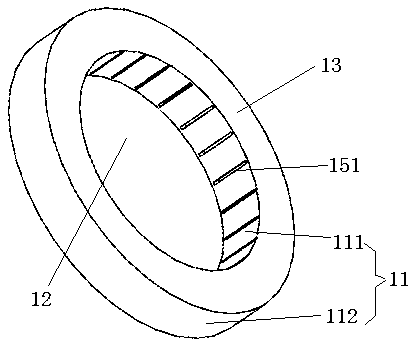

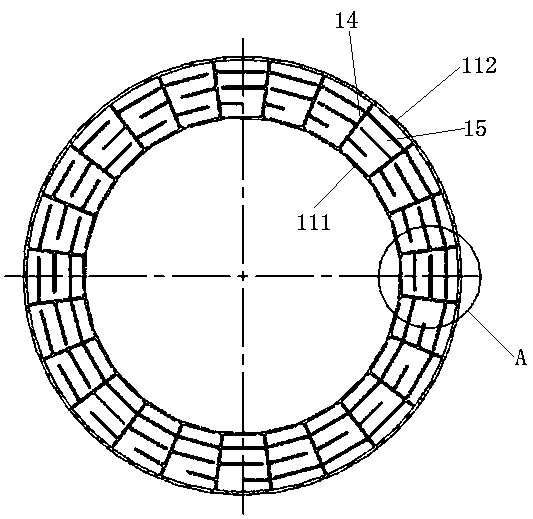

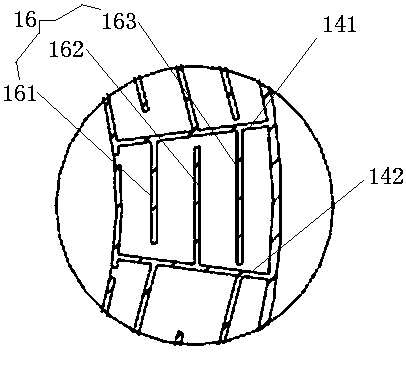

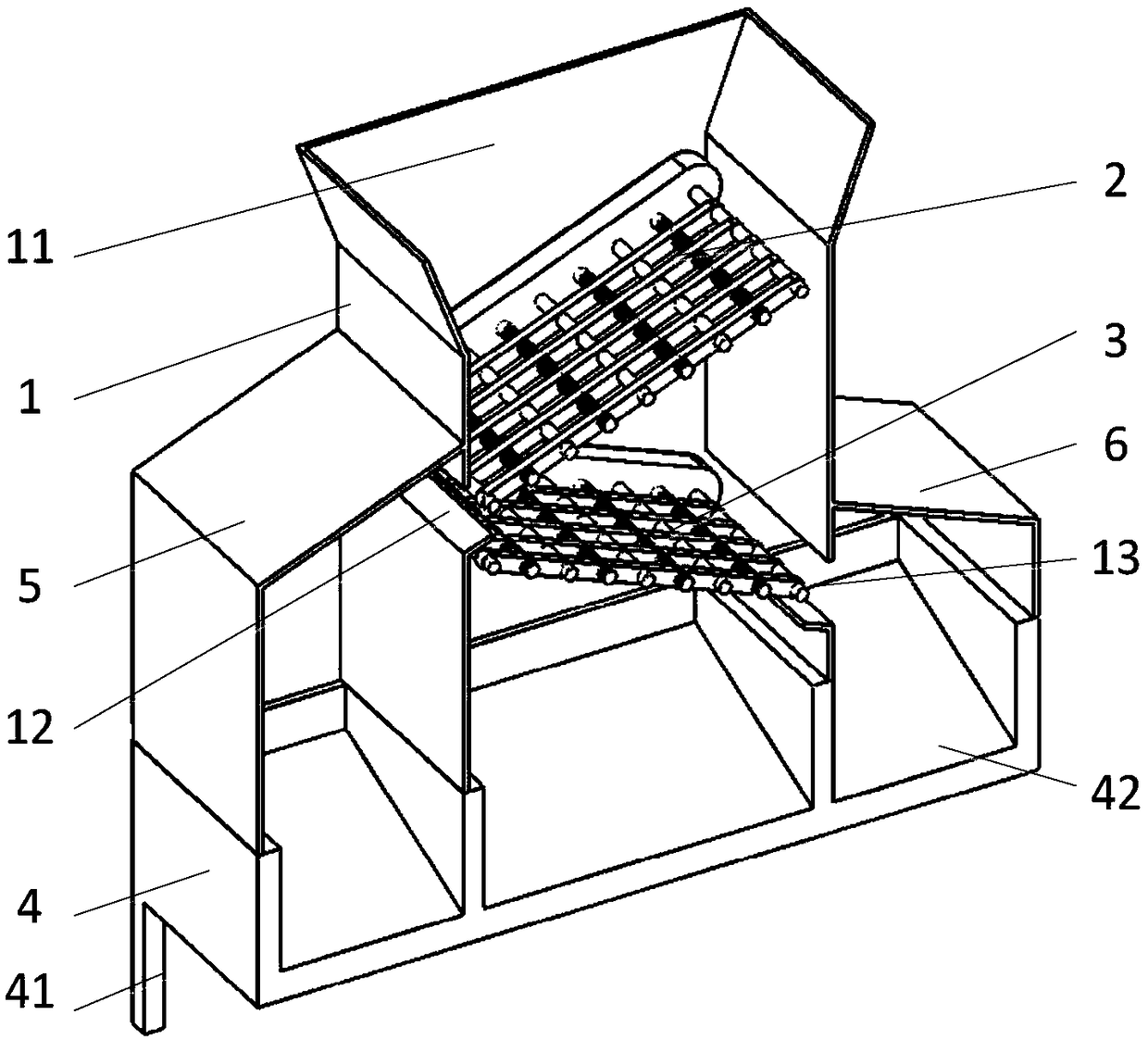

Noise reduction device and gas water heater

The invention discloses a noise reduction device and a gas water heater. The noise reduction device comprises a bucket-shaped body, wherein the bucket-shaped body is defined by connecting a circumferential wall and a bottom wall, and one end of the bucket-shaped body is open. The circumferential wall comprises an inner circumferential wall and an outer circumferential wall. An air inlet channel isdefined by the middle of the inner circumferential wall. A gap is formed between the inner circumferential wall and the outer circumferential wall. A cavity is divided by first partition plates intomultiple sound attenuation cavities, at least one second partition plate is arranged in each sound attenuation cavity, each sound attenuation cavity is divided by the corresponding second partition plates into multiple layers of sub sound attenuation cavities, and the sub sound attenuation cavities are independent of each other. The second partition plates are perpendicular to the first partitionplates, and each sub sound attenuation cavity is provided with at least one sound inlet. The noise reduction device effectively absorbs noise entering the structure, and therefore sounds are effectively prevented from being leaked from the structure; and through inner structural design, sound absorption and noise reduction for different frequencies can be achieved, and noise spreading out from a box can be effectively reduced. In addition, the noise reduction device basically has no influence on the wind quantity and wind pressure, and the wind inlet quantity cannot be influenced.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +2

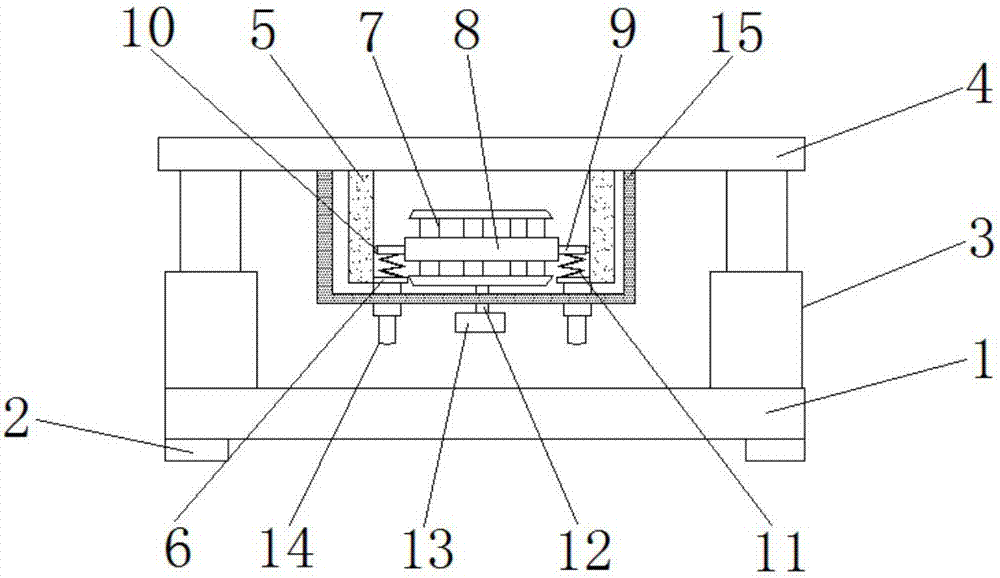

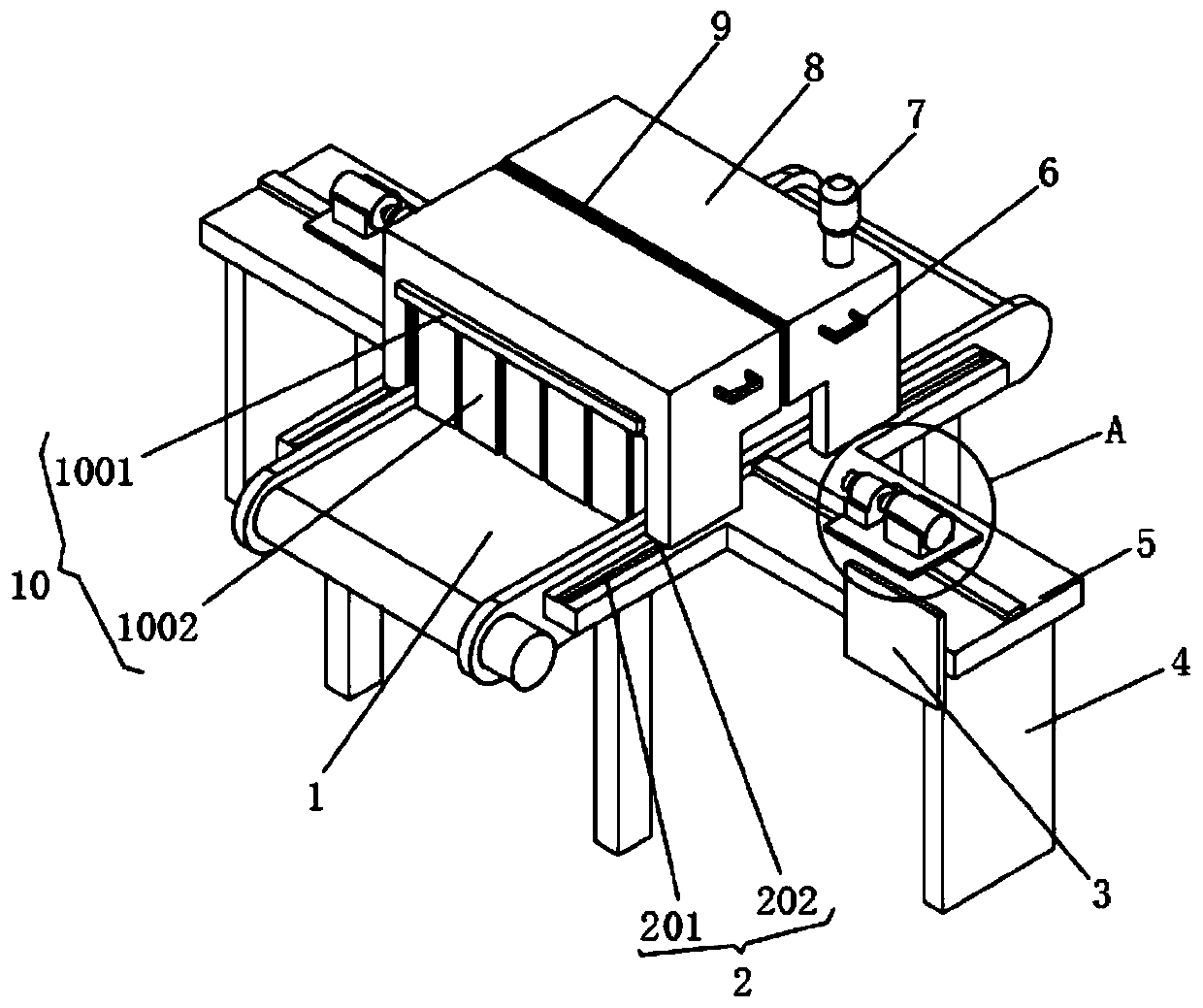

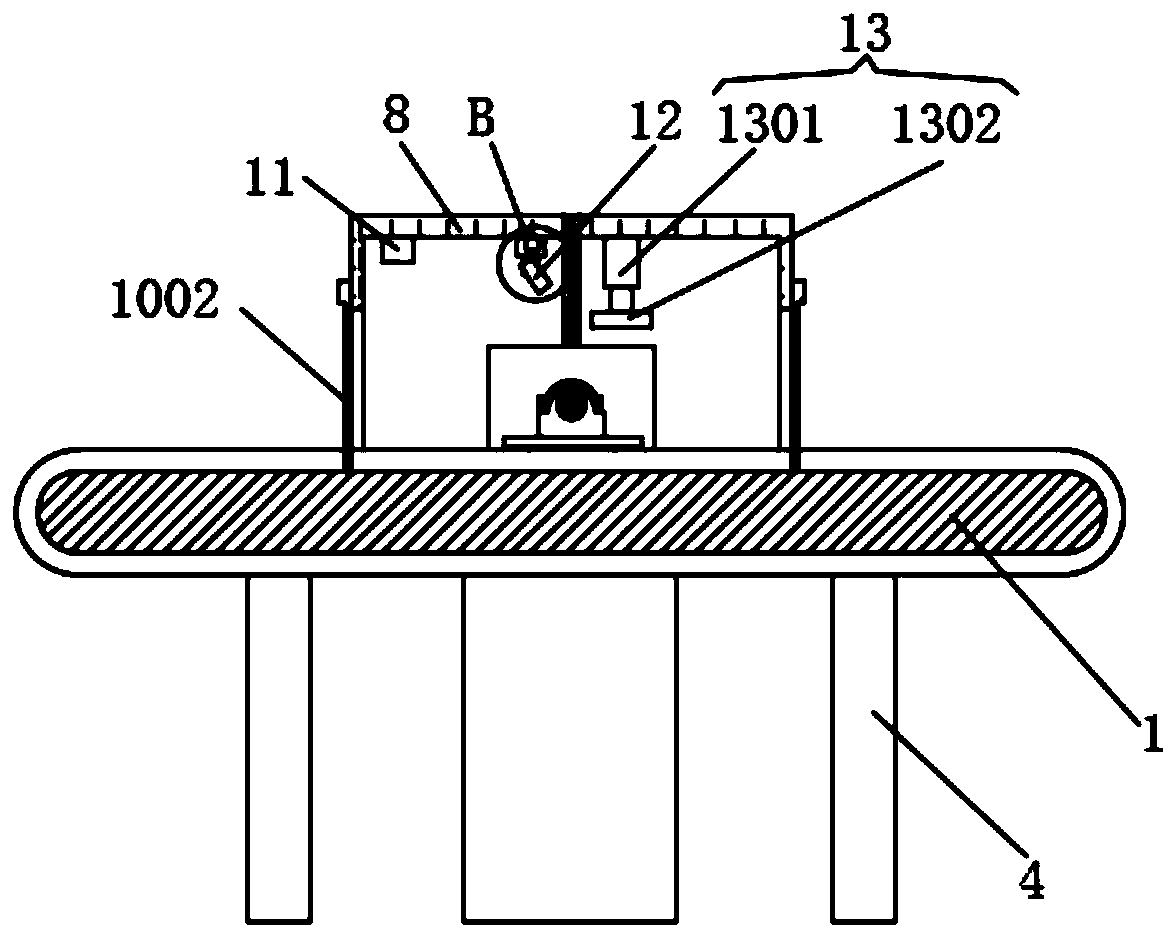

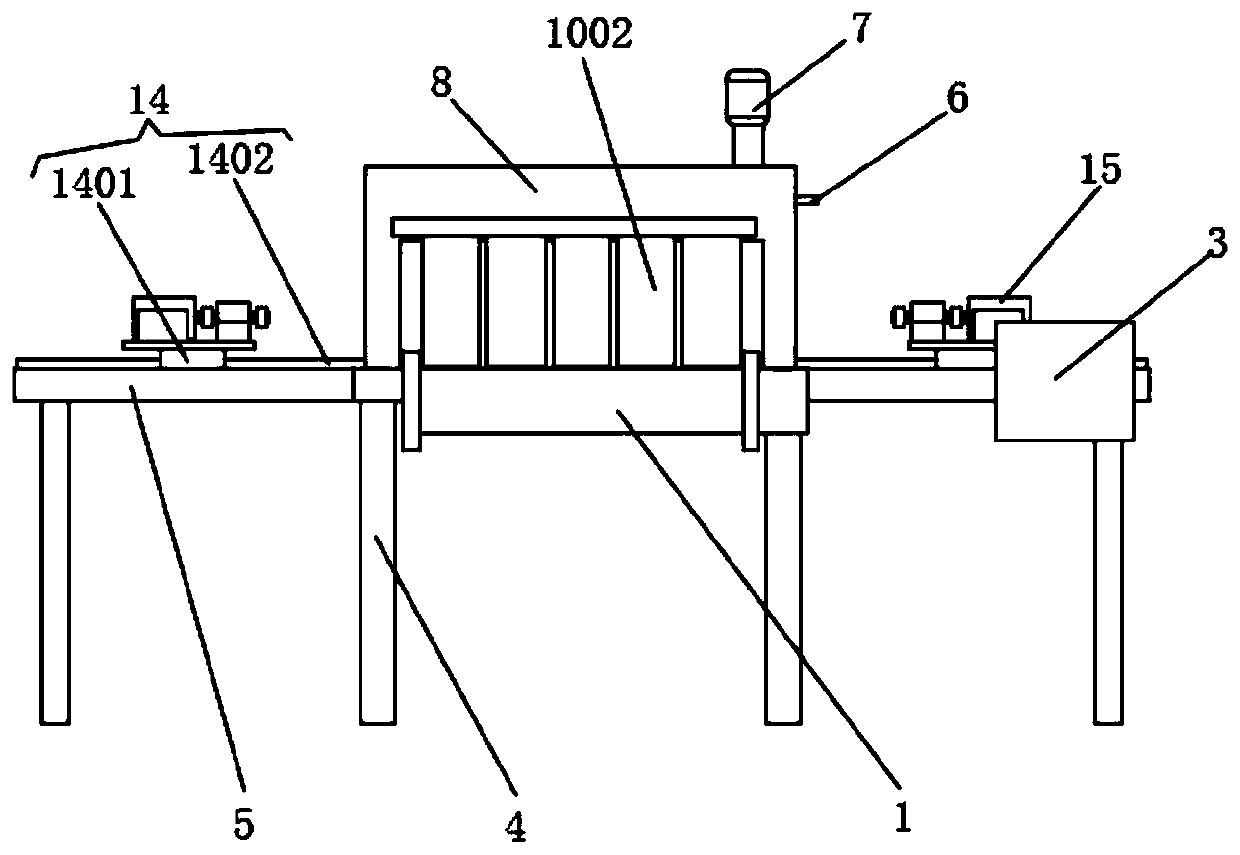

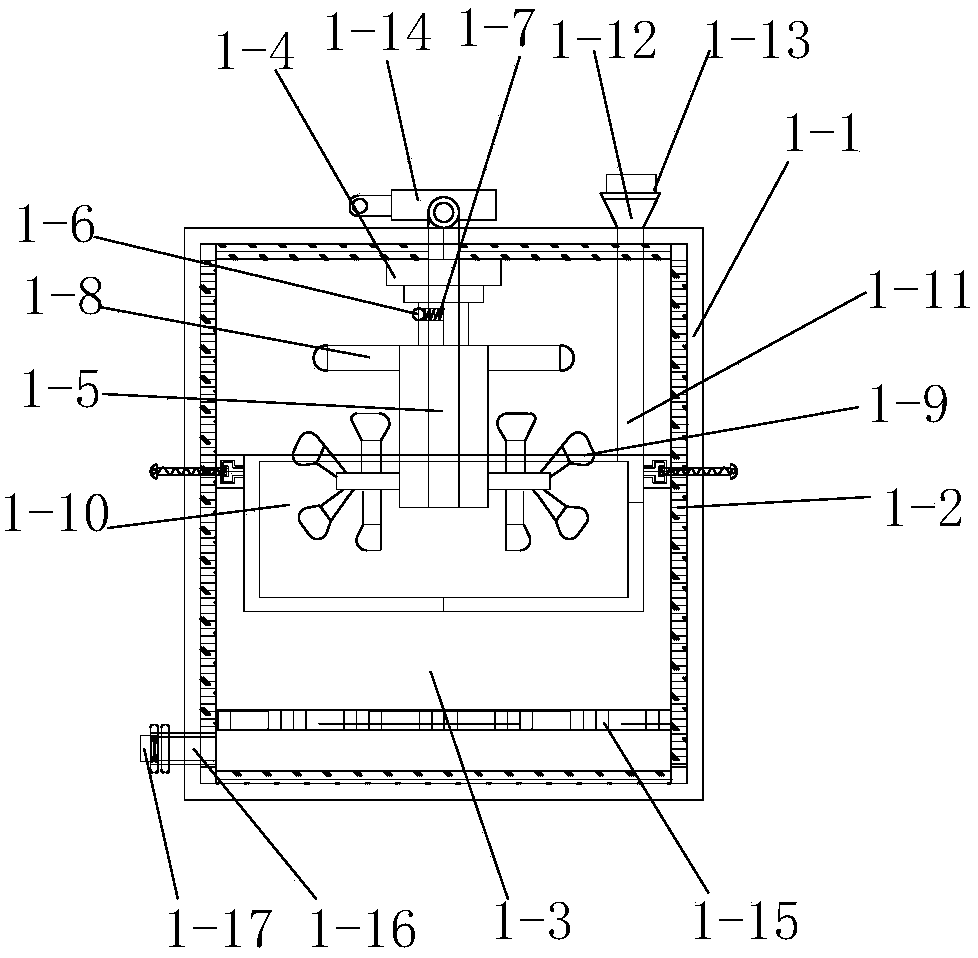

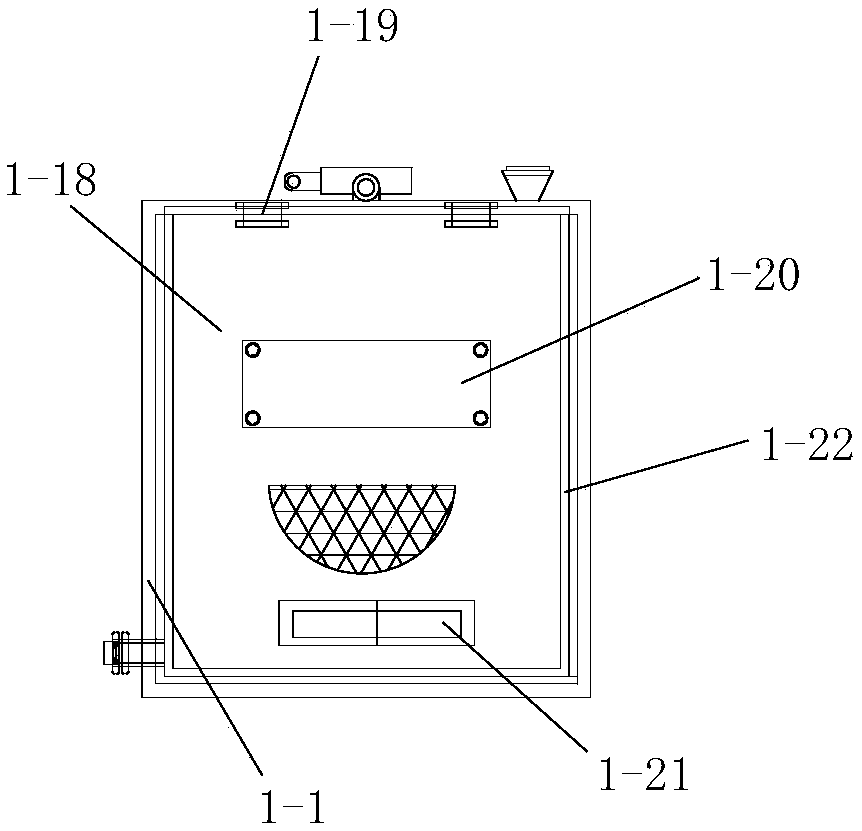

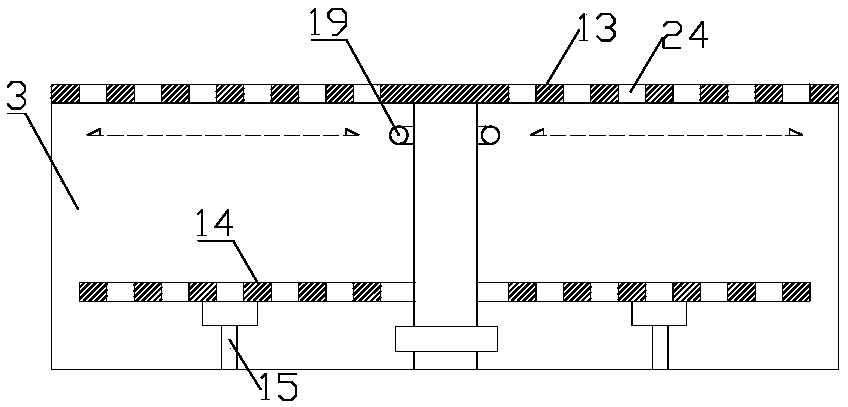

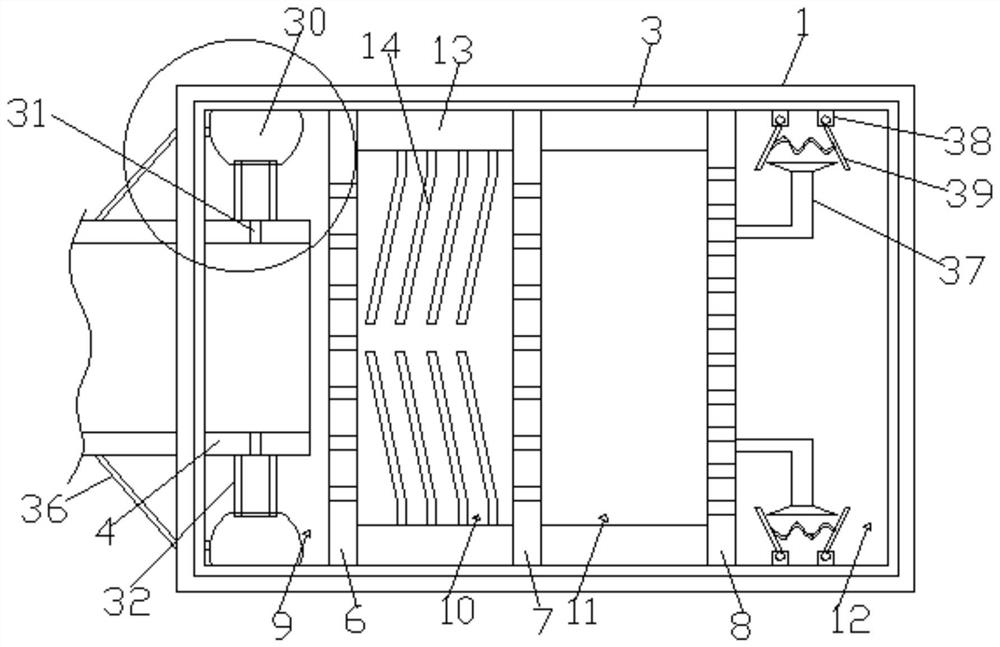

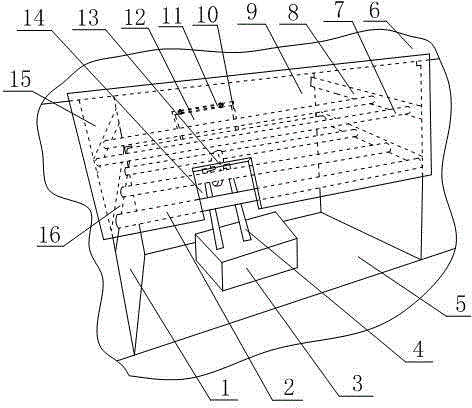

Speed reducer operation performance test platform

ActiveCN111044286AReduce outgoingPrevent flying outProgramme controlMachine part testingInfrared thermometryNoise detection

The invention discloses a speed reducer operation performance test platform. The platform comprises a belt conveyor, detection boxes, protection mechanisms, an infrared thermometer, a first test mechanism, a first moving mechanism, a stepping motor and a second test mechanism. T-shaped plates are arranged on the front surface and the rear surface of the belt conveyor; supporting legs are arrangedat the bottoms of the T-shaped plates and the bottom of the belt conveyor, the two sets of detection boxes are symmetrically arranged and assembled on the T-shaped plate through sliding mechanisms, audible and visual alarms are arranged on the detection boxes, noise detectors are arranged on the inner cavity faces of the detection boxes, and the protection mechanisms are installed at inlets and outlets of the two sets of detection boxes. The speed reducer operation performance test platform can perform integrated detection, shorten the test time, reduce the number of users, improve the test efficiency, improve the accuracy of various test results and improve the safety during detection.

Owner:广东馥融传动科技有限公司

Method for planting photinia fraseri dress

InactiveCN108476846AEfficient preparationEasy to observe workSeed and root treatmentGrowth substratesPhotinia fraseriSurvival rate

The invention discloses a method for planting photinia fraseri dress. The method comprises the following steps of (A) seed pretreatment; (B) substrate preparation; (C) seedbed leveling; (D) sowing andearthing; (E) nursery management; (F) sapling transplanting; (G) sampling raising, management and protection. According to the method for cultivating and planting the photinia fraseri dress, the germination rate of seeds is 97.8%, the germinative force is 96.5%, 30 days after germination, the survival rate reaches up to 98.9%, three months after sowing, the number of the photinia fraseri dress seedlings with 90%-110% of average seedling height accounts for 90.3% of the total number of the photinia fraseri dress, and the number of the photinia fraseri dress seedlings with 90%-110% of average ground diameter accounts for 96.3% of the total number of the photinia fraseri dress.

Owner:XINYANG AGRI & FORESTRY UNIV

Genetic breeding method of oil-tea camellia

InactiveCN108377902AEfficient preparationEasy to observe workCultivating equipmentsPlant genotype modificationCamellia oleiferaLoment

The invention discloses a genetic breeding method of oil-tea camellia. The genetic breeding method comprises the following steps: (A) collecting oil-tea camellia pollen of the oil-tea camellia in theXinyang prefecture at a full-bloom stage; after naturally drying, preserving at 4 DEG C; standing for 1 to 2h under a room-temperature condition before pollination; preparing the oil-tea camellia pollen and ultrapure water according to the mass ratio of 1 to (500 to 1000) to obtain oil-tea camellia pollen liquid; then spraying the oil-tea camellia pollen liquid on female plants of the oil-tea camellia in the south of Hunan for 2 to 4 times, wherein the time interval of each time of spraying is 3 to 5 days; fertilizing according to fertilization conditions of a land of the pollinated female plants; after fruits become ripe, collecting fruits to obtain hybridized oil-tea camellia seeds and pre-treating the hybridized seeds; (B) preparing a base material; (C) flattening a seedling bed; (D) sowing the seeds and coverings oil; (E) managing a nursery garden; (F) transplanting tree seedlings; (G) fostering, managing and protecting the tree seedlings. By adopting the genetic breeding method ofthe oil-tea camellia, an oil-tea camellia variety applicable to the regions in the south of Hunan can resist accidental low-temperature weathers and the survival rate of oil-tea camellia seedlings isimproved.

Owner:XINYANG AGRI & FORESTRY UNIV

Noise reduction device and gas water heater

The invention discloses a noise reduction device and a gas water heater. The noise reduction device comprises a barrel-shaped body with an open end defined by a peripheral wall and a bottom wall, theperipheral wall comprises an inner peripheral wall and an outer peripheral wall, a gap is formed between the inner peripheral wall and the outer peripheral wall, one ends of the inner peripheral walland the outer peripheral wall are hermetically connected with the bottom wall, the other ends of the inner peripheral wall and the outer peripheral wall are connected through a connecting panel, and aclosed cavity is defined among the bottom wall, the inner peripheral wall, the outer peripheral wall and the connecting panel. The cavity is partitioned by partition plates to form a plurality of silencing cavities, and sound inlets of the silencing cavities are formed in the inner peripheral wall. According to the noise reduction device, the sound passing through the structure can be effectivelyabsorbed, so that the sound can be effectively prevented from leaking out, sound absorption and noise reduction aiming at different frequencies can be realized through the internal structure design,and noise transmitted out of a box body can be effectively reduced. In addition, the noise reduction structure almost has no influence on the air quantity and the air pressure and does not influence the air inlet quantity.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

Multi-level ore screening device

ActiveCN108620309AAchieve primary screeningRealize multi-stage screening with one feedingSievingScreeningEngineeringMachining

The invention discloses a multi-level ore screening device, and belongs to ore mining and machining devices. The multi-level ore screening device comprises a main box body which is in the shape of a square barrel with upper and lower openings, an upward horn-shaped feed inlet is formed in the upper portion of the main box body, and a first outlet and a second outlet are formed in two opposite sidewalls correspondingly. The multi-level ore screening device further comprises a first screening device, a second screening device and a discharging frame, wherein the first screening device is fixedin the main box body and located on the upper portion of the main box body, and the lower end of the first screening device faces the first outlet; the second screening device is fixed in the main boxbody and located on the lower portion of the main box body, the second screening device is located under the first screening device, and the lower end of the second screening device faces the secondoutlet; and the discharging frame is located under the main box body and comprises a support and three discharge outlets which are arranged side by side. The multi-level ore screening device solves the technical problems that ore is likely to get stuck in screening holes to block the screening holes and production work is affected due to the fact that crushed ore is mostly in irregular shapes andpointed corners are located on the surface of ore, and existing screening devices cannot carry out one-time multi-level screening on large and small ore.

Owner:广西华洋矿源材料有限公司

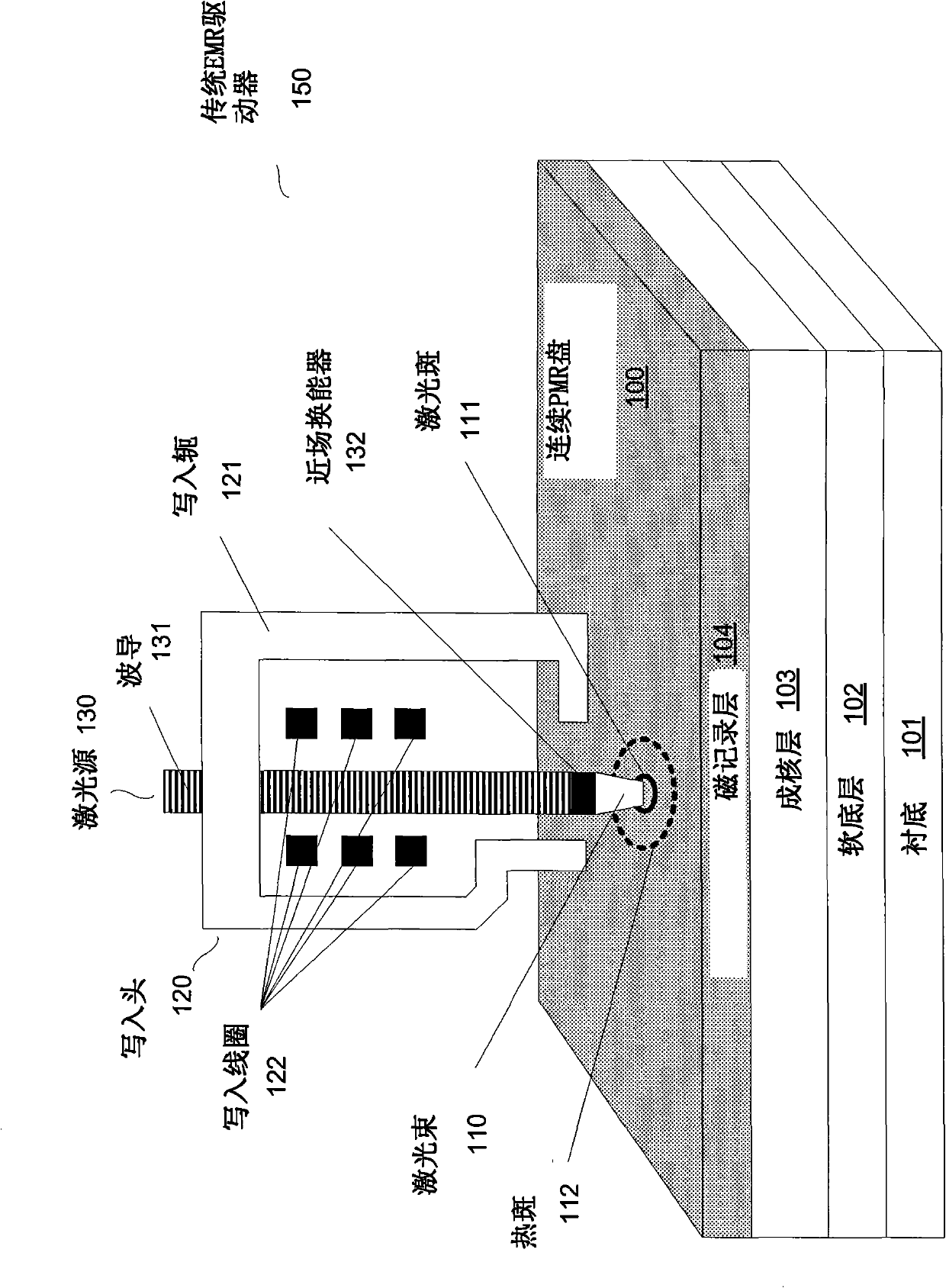

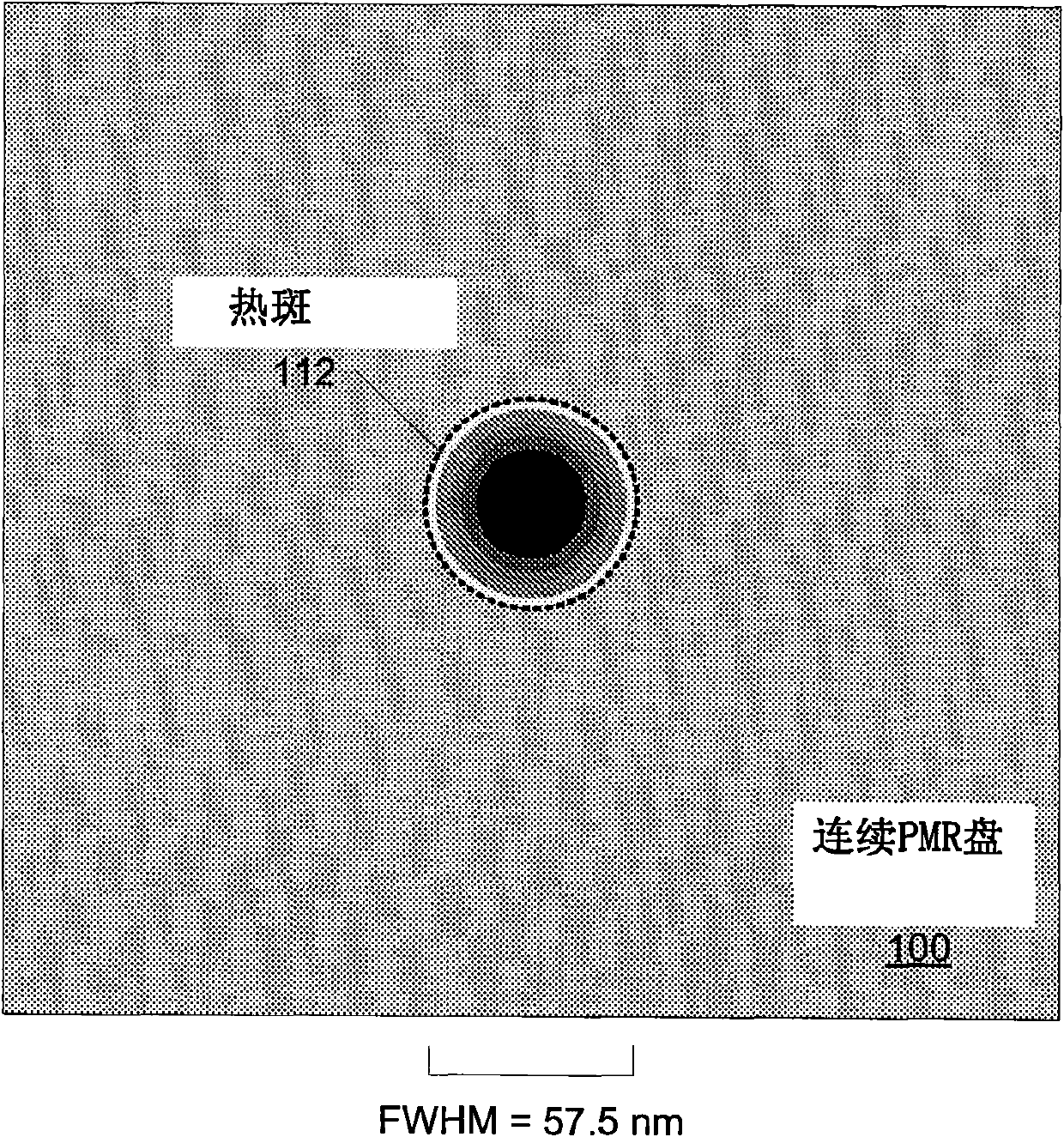

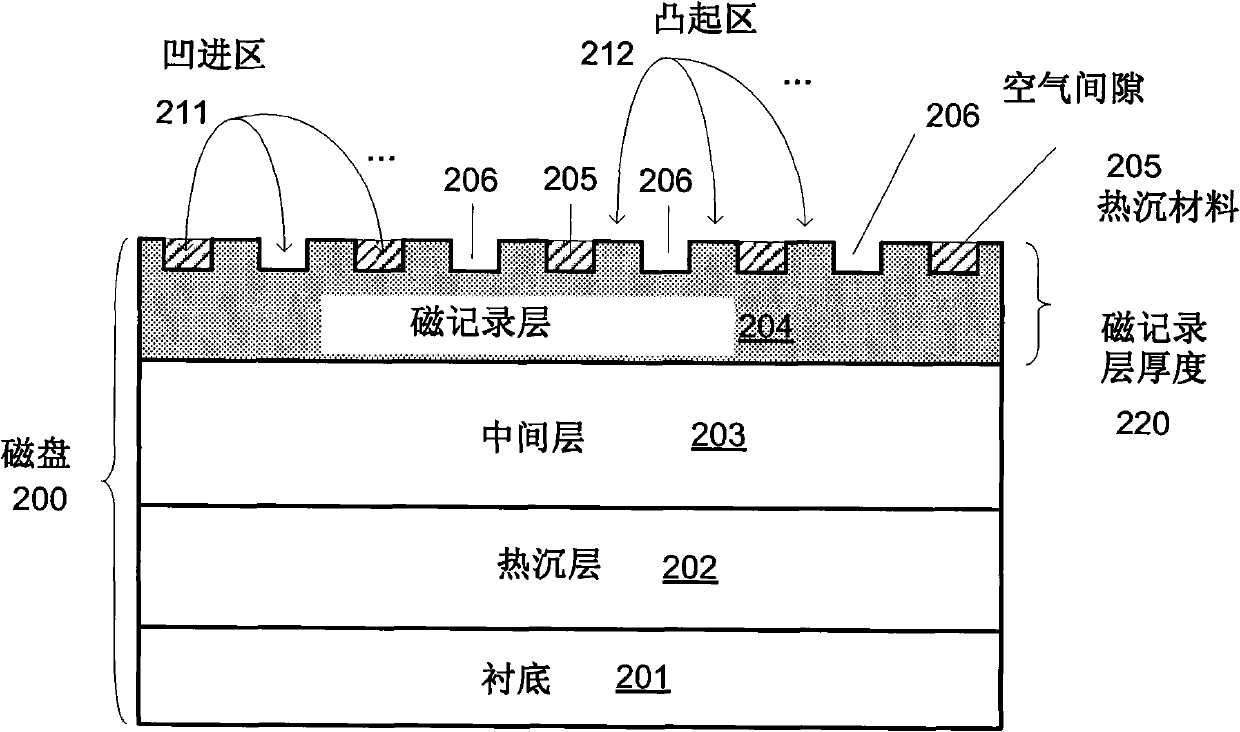

Energy assisted discrete track media with heat sink

ActiveCN101996646AExtended cooldownReduce outgoingNanoinformaticsPatterned record carriersEngineeringConductive materials

The invention relates to an energy assisted discrete track media with heat sink. A discrete track perpendicular magnetic recording (PMR) disk and a method of fabricating the disk are described. The PMR disk may include a heat sink layer disposed above a substrate, intermediate layers disposed above the heat sink layer, and a magnetic recording layer disposed above the intermediate layers. The magnetic recording layer may have raised and recessed areas, where a heat conductive material may be disposed within one or more of the recessed areas.

Owner:WESTERN DIGITAL TECH INC

Landscape design method for leisure square in urban planning

InactiveCN108505774AEfficient preparationEasy to observe workSecateursSpadesLandscape designWater resources

The invention discloses a landscape design method for a leisure square in urban planning. The landscape design method comprises the following steps that (1) the leisure square is divided into a squareentrance landscape area, a theme culture square landscape area, an old-age people activity landscape area, a young children activity landscape area, a middle-young age people activity landscape areaand a ring square landscape area; (2) the theme culture square landscape area is designed; (3) the ring square landscape area is designed; (4) the young children activity landscape area is designed; (5) the old-age people activity landscape area is designed; (6) the middle-young age people activity landscape area is designed; and (7) the square entrance landscape area is designed. According to activity characteristics of crowds, the multiple activity areas and matched public facilities are designed; and water resources in the leisure square are reasonably utilized by designing a plurality of sets of fountain drainage pipelines, a truncated-cone-shaped landscape platform protruding out of the ground is designed and can be watched from a long distance, and accidents are avoided.

Owner:XINYANG AGRI & FORESTRY UNIV

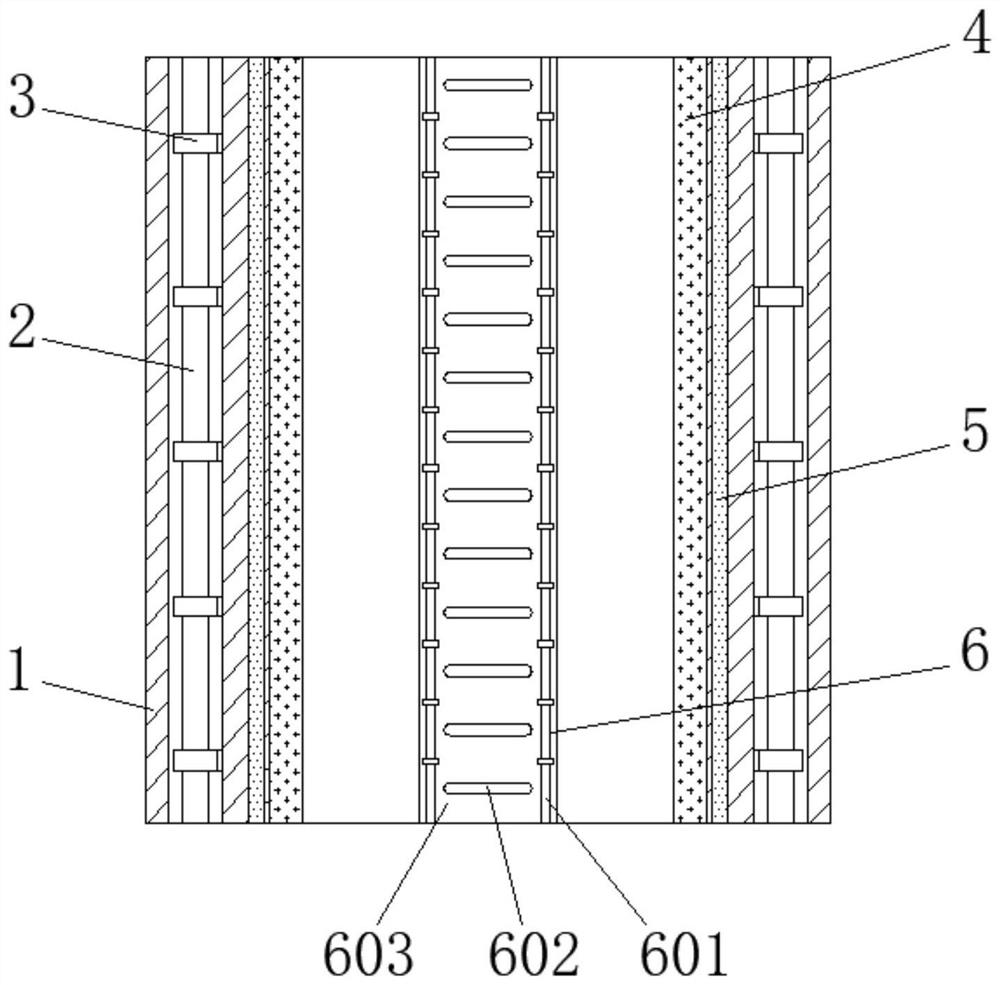

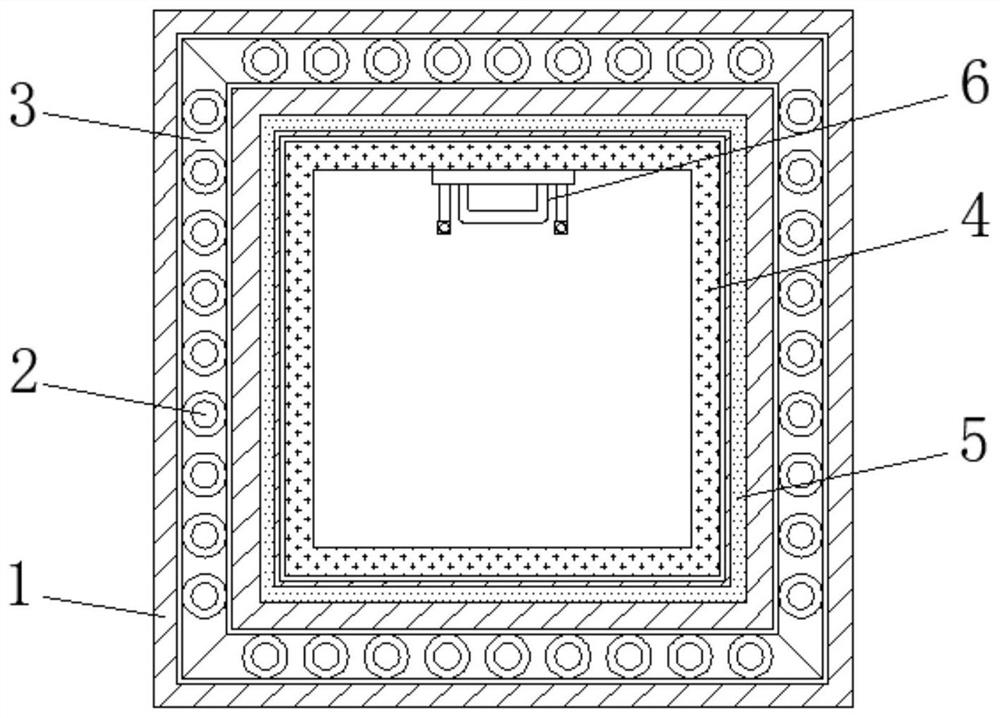

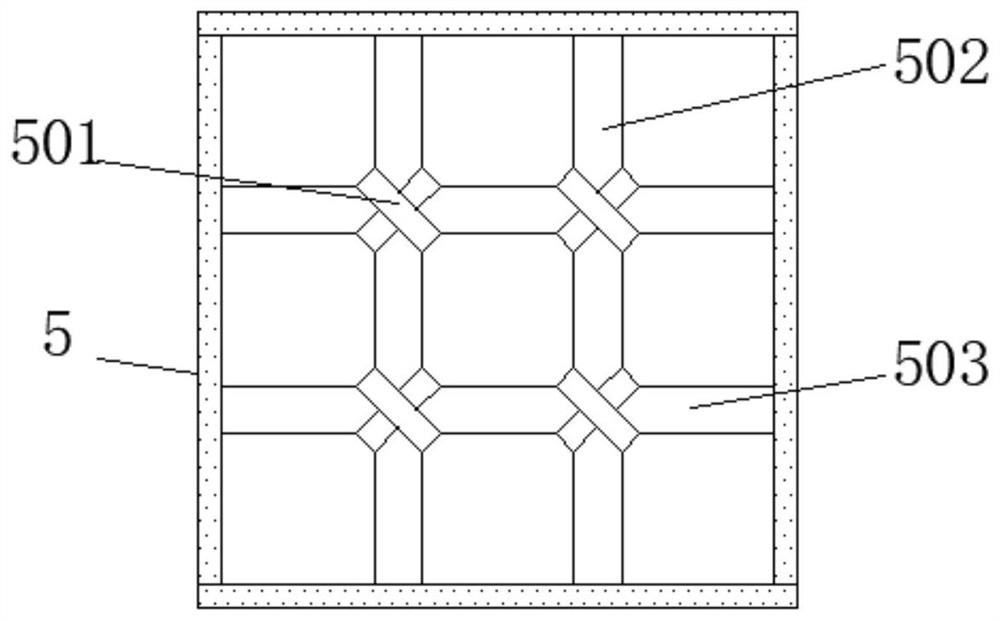

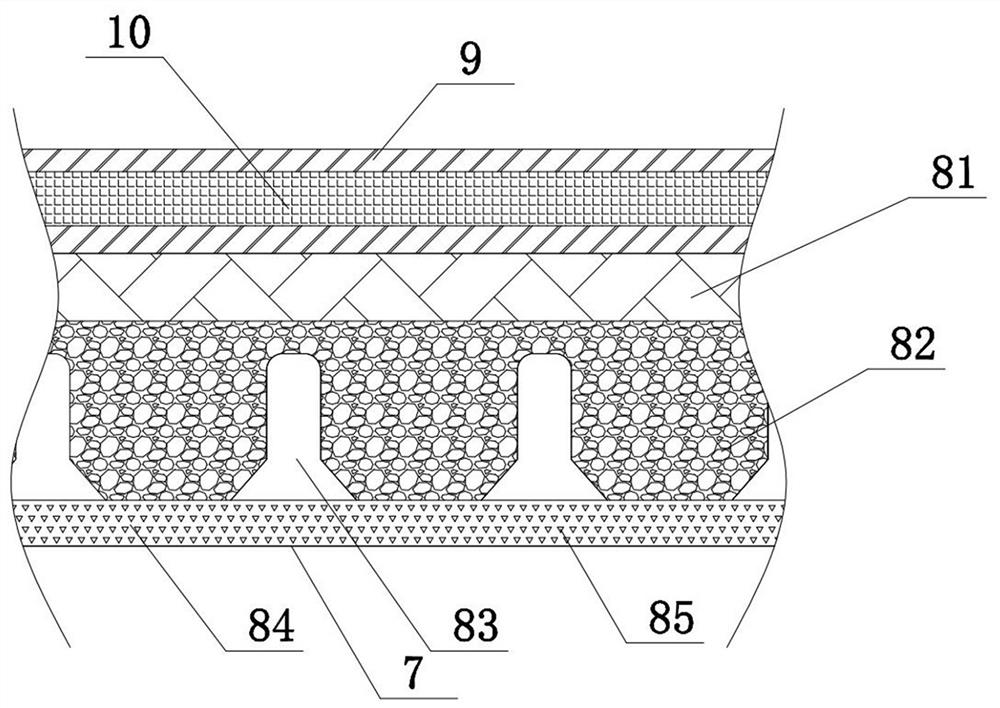

Core tube for architectural design

InactiveCN112554332AImprove noise reductionEnhance crack resistanceBuilding repairsSound proofingRebarAcoustic noise reduction

The invention discloses a core tube for architectural design. The core tube comprises a core tube body, vertical steel bars and transverse steel bars; the vertical steel bars are arranged in the coretube body; the transverse steel bars are arranged on the surfaces of the vertical steel bars; an anti-cracking structure is arranged on the inner side wall of the core tube body; a sound insulation structure is arranged in the anti-cracking structure; and a maintenance structure is arranged at one end in the sound insulation structure. Protection plates, sound insulation cotton and sound insulation plates are installed in the core tube, during later use, noises in the core tube can be isolated by the sound insulation plates and the sound insulation cotton, noise transmission can be reduced, influence on people in a building is avoided, the protection plates installed on the surfaces of the sound insulation plates and the sound insulation cotton can protect the sound insulation plates and the sound insulation cotton and prevent the sound insulation plates and the sound insulation cotton from being damaged and causing influence on use, and therefore the noise reduction performance of thecore tube is enhanced.

Owner:上海席得建筑设计有限公司

Dough kneading device convenient for feeding

InactiveCN112889860AReduce wasteImprove sound insulationMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGlass coverElectric machinery

The invention discloses a dough kneading device convenient for feeding, and relates to the technical field of dough kneading. The dough kneading device comprises a bottom frame; the upper surface of the bottom frame is fixedly connected with a telescopic rod; the upper end of the telescopic rod is fixedly connected with a mounting frame; the lower surface of one end, far away from the telescopic rod, of the mounting frame is fixedly connected with two T-shaped plates; the T-shaped plate is fixedly connected with the upper wall of a double-layer sound insulation glass cover through screws; furthermore, a plurality of silencing mechanisms are fixedly connected to the peripheral surface of the double-layer sound insulation glass cover; a motor is mounted in the mounting frame; the output end of the motor is fixedly connected with a dough kneading mechanism; two supporting plates are fixedly connected to the upper surface of the bottom frame; and a kneading cylinder is rotatably connected between the two supporting plates. The device has good sound insulation effect, so that the influence of noise during kneading on a user is reduced; and meanwhile, the double-layer sound insulation glass cover also can prevent flour from splashing so as to avoid pollution or harm to the user.

Owner:ANHUI SHENRAN FOOD CO LTD

Vibrating sieving machine with muting box

The invention discloses a vibrating sieving machine with a muting box. The vibrating sieving machine comprises the muting box and a vibrating sieving machine main machine mounted in the muting box, wherein the muting box comprises a base and two sound insulation half box bodies, the two sound insulation half box bodies are symmetrically mounted on the top of the base left and right, the front sides of the two sound insulation half box bodies are connected through a lock catch, a fixing column is vertically arranged on the part, located at the joint between the two sound insulation half box bodies, of the top of the rear side of the base, the bottom of the fixing column is fixedly connected with the top of the rear side of the base, the rear sides of the two sound insulation half box bodiesare hinged to the fixing column through a plurality of hinges, one sides of the hinges are fixedly connected with the outer side of the fixing column, and the other sides of the hinges are fixedly connected with the inner walls of the rear sides of the sound insulation half box bodies; and sealing strips are arranged between the bottom of the sound insulation half box bodies and the base, betweenthe front sides of the two sound insulation half box bodies, between the rear sides of the two sound insulation half box bodies, and between the top sides of the two sound insulation half box bodiescorrespondingly. According to the vibrating sieving machine, the muting box is arranged so that noise generated during operation of the vibrating sieving machine can be greatly reduced, and the assembly and the disassembly are convenient.

Owner:XIAN UNIV OF SCI & TECH

Convenient-to-install sound insulation device for building construction and installation method thereof

PendingCN112282506AEasy to moveEasy to disassemblePhotovoltaic supportsSolar heating energyIsosceles trapezoidInsulation layer

The invention discloses a convenient-to-install sound insulation device for building construction and an installation method thereof. The convenient-to-install sound insulation device comprises a supporting mechanism, a clamping plate is clamped to the top of the supporting mechanism, a frame body is fixedly connected to the top of the clamping plate, a bearing frame is fixedly installed on the back face in the frame body, a frame groove is formed in an inner ring of the frame body, a rubber clamping frame is arranged in the frame groove, a sound insulation screen is clamped to the inner sideof the rubber clamping frame, the section of the back face of the sound insulation screen is in an isosceles trapezoid shape, a sound insulation layer is arranged in the sound insulation screen, a tempered glass layer is fixedly installed on the back face of the sound insulation screen, a photovoltaic panel is arranged in the tempered glass layer, a lighting mechanism is arranged at the top of theframe body, and digging grooves are formed in the front face and the back face of the left side and the right side of the frame body correspondingly. The device can be spliced at will according to needs, meanwhile, splicing, mounting and dismounting are convenient, the sound insulation effect is good, and therefore the device is high in practicability, wide in application prospect and worthy of application and popularization.

Owner:深圳市嘉鑫隆钢结构有限公司

Method for sowing and propagating emmenopterys henryi

InactiveCN108496678AEfficient preparationEasy to observe workSecateursSpadesFruit treeEmmenopterys henryi

The invention discloses a method for sowing and propagating emmenopterys henryi. The method comprises the following steps: (A) seed pretreatment; (B) substrate preparation; (C) seedbed levelling; (D)sowing and earthing; (E) nursery management; (F) sapling transplantation; and (G) sapling tending and management and protection. The method disclosed by the invention has a high germination rate and neat seedling emergence, and is suitable for large-scale sowing and propagating of the emmenopterys henryi in forestry.

Owner:XINYANG AGRI & FORESTRY UNIV

Manufacturing method of automobile muffler and muffler device

InactiveCN109894811ASuppress noiseFirmly connectedAssembly machinesSilencing apparatusCore componentEngineering

The invention discloses a manufacturing method of an automobile muffler and a muffler device. A core component is assembled firstly, parts, located between two separating plates of the core component,of a buffer pipe, an air inlet buffer pipe and a venting buffer pipe are coated with sound-absorbing cotton, then the core component coated with the sound-absorbing cotton is placed into an automobile muffler casing, two ends of the automobile muffler casing are blocked by the aid of end covers, and the automobile muffler is formed. The buffer pipe of the muffler is arranged between the air inletbuffer pipe and the venting buffer pipe, the outer side of the buffer pipe, the outer side of the air inlet buffer pipe and the outer side of the venting buffer pipe are coated with the sound-absorbing cotton, and the sound-absorbing cotton is closely attached to the separating plates on two sides. According to the manufacturing method, the parts, located between the two separating plates of thecore component, of the buffer pipe, the air inlet buffer pipe and the venting buffer pipe are coated with the sound-absorbing cotton, then the two ends of the automobile muffler casing are blocked bythe aid of the end covers, and the automobile muffler is formed, so that the noise can be suppressed substantially.

Owner:重庆市大林机械发展有限公司

Low-noise silencer

PendingCN113611273AAvoid cloggingAvoid easy cloggingDispersed particle filtrationSound producing devicesNoiseEngineering

The invention discloses a low-noise silencer. The low-noise silencer comprises a first circular silencing pipe and a second circular silencing pipe, wherein the diameter of the first silencing pipe is smaller than that of the second silencing pipe, and the first silencing pipe and the second silencing pipe are connected through an installation sealing mechanism; first sound absorption cotton is arranged on the inner wall of the first hush pipe and the inner wall of the second hush pipe, an inlet pipe is installed on the first hush pipe, and an outlet pipe is installed on the second hush pipe. The low-noise silencer is advantaged in that the working principle of a sound absorption plate in a third noise reduction cavity is the same as that of a sound absorption plate in a second small noise cavity, then the sound absorption plate enters a fourth noise reduction cavity, noise reduction is conducted again through an arranged second noise reduction mechanism, therefore, the good noise absorption effect is achieved, finally, low-noise frequency band noise enters a second noise reduction pipe, and the first sound absorption cotton in the second silencing pipe achieves final silencing so that the noise is reduced to be extremely low.

Owner:连云港久盛电力辅机有限公司

Manufacturing method of automobile muffler and noise elimination device

InactiveCN106089363ASuppress noiseFirmly connectedSilencing apparatusMachines/enginesEngineeringMuffler

The invention discloses a manufacturing method of an automobile muffler and a noise elimination device. The manufacturing method comprises the steps of assembling a core assembly; wrapping a buffer tube, an air inlet buffer tube and an exhaust buffer tube between two partition plates of the core assembly with sound absorbing cotton; then, placing the core assembly wrapped with the sound absorbing cotton in an automobile muffler shell; and plugging the two ends of the automobile muffler shell with end covers to form the automobile muffler. The manufacturing method is characterized in that the buffer tube of the muffler is arranged between the air inlet buffer tube and the exhaust buffer tube; the outer sides of the buffer tube, the air inlet buffer tube and the exhaust buffer tube are wrapped with the sound absorbing cotton; and the sound absorbing cotton tightly fits the partition plates on the two sides. According to the manufacturing method, the buffer tube, the air inlet buffer tube and the exhaust buffer tube between the two partition plates of the core assembly are wrapped with the sound absorbing cotton, the two ends of the automobile muffler shell are plugged with the end covers, the automobile muffler is formed, and noise can be suppressed greatly.

Owner:湖南海特汽车部件有限公司

Mechanical device capable of achieving noise insulation during cutting

The invention discloses a mechanical device capable of achieving noise insulation during cutting. The mechanical device comprises a supporting system internally provided with a cavity. The cavity penetrates through the two ends of the supporting system. The two ends of the supporting system are provided with sealing covers respectively. The top ends of the sealing covers are arranged above the top end of the cavity. Gaps exist between the bottom ends of the sealing covers and the bottom of the cavity. Each sealing cover is provided with a feed inlet and a discharge outlet which are communicated with the cavity, wherein the feed inlet and the discharge outlet are respectively communicated with the bottom end of the corresponding sealing cover. Discharge doors are arranged in the discharge outlets. Connecting rings are arranged between the discharge doors and the top ends of the discharge outlets. The connecting rings are fixed to the top ends of the discharge outlets. Rotating shafts are arranged in the connecting rings. The discharge doors are fixed to the rotating shafts, and the rotating shafts can rotate around the axes of the rotating shafts. The cutting device is simple in structure, noises generated during cutting are isolated through the sealing covers so as to be weakened and transmitted out, the physical and psychological health of operators is protected, and the national regulation for preventing and controlling noise pollution is met.

Owner:CHENGDU NONDO FURNITURE

Mechanical seal assembly capable of measuring internal pressure for carbon steel reaction kettle

InactiveCN111701554AAffect processing qualityPreventing influence on the confidential pressure detection dataProcess control/regulationChemical/physical/physico-chemical stationary reactorsStructural engineeringPipe

The invention discloses a mechanical seal assembly capable of measuring internal pressure for a carbon steel reaction kettle. The mechanical seal assembly comprises a bottom plate and a control box, wherein self-locking rollers are fixed on the lower side of the bottom plate; a first carbon steel reaction kettle shell is fixed on the upper side of the support rod; the lower side of the oil conveying pipe is in threaded connection with a filtering assembly through a hollow threaded fixing piece; a material guiding pipe is arranged on the right side of the oil conveying pipe, a first fixing plate is fixed to the inner wall of the upper side of the first carbon steel reaction kettle shell, a second carbon steel reaction kettle shell is fixed to the inner wall of the annular fixing plate, anda feeding port penetrates through the right end of the upper side of the second carbon steel reaction kettle shell. According to the mechanical sealing assembly capable of measuring the internal pressure for the carbon steel reaction kettle, the sealing assembly is arranged, and the sealing box, the sealing strip and the first sealing ring in the sealing assembly interact with one another to perform multi-layer sealing, so that the sealing pressure detection data are prevented from being influenced when the joints of the pressure measuring pipe, the pressure discharging pipe and the shell of the second carbon steel reaction kettle are not sealed thoroughly.

Owner:JIANGSU YITONG FLUID TECH

Agriculture and forestry combined ecological economic system

InactiveCN108575492AEfficient preparationEasy to observe workSeed and root treatmentClimate change adaptationForest industryFruit tree

The invention discloses an agriculture and forestry combined ecological economic system comprising the following steps: (A) seed pretreatment; (B) substrate preparation; (C) seedbed leveling; (D) sowing and soil covering; (E) seedling nursery management; (F) sapling seedling transplanting; and (G) sapling seedling nursing as well as management and protection. The method disclosed by the inventionis suitable for planting emmenopterys henryi in the forestry on a large scale, and at the young seedling stage of the emmenopterys henryi, the emmenopterys henryi and peanuts are shaded by corns, thepeanuts are used for fixing nitrogen in the corns, and the emmenopterys henryi, the peanuts and the corns are coordinated with each other to develop; and the emmenopterys henryi is high in germinationrate, ordered in seedling emergence and suitable for large-scale sowing and reproduction in the forestry.

Owner:XINYANG AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com