Multi-level ore screening device

A screening device and ore technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of inability to sieve large and small ores at one time, ores are easy to get stuck on the mesh, affecting production work, etc., and achieve structural Sturdy and reliable, reduce noise transmission, reduce dust flying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

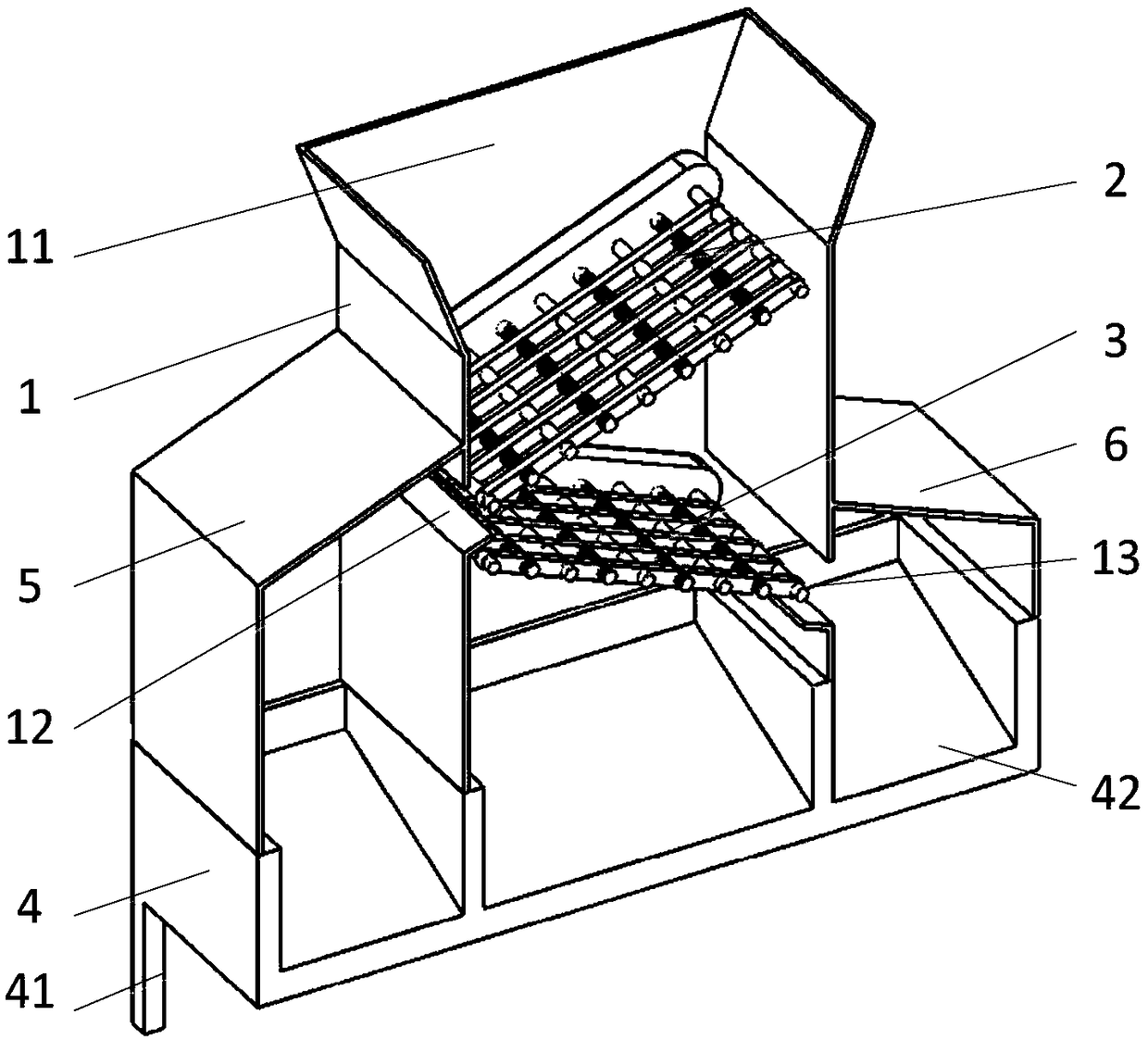

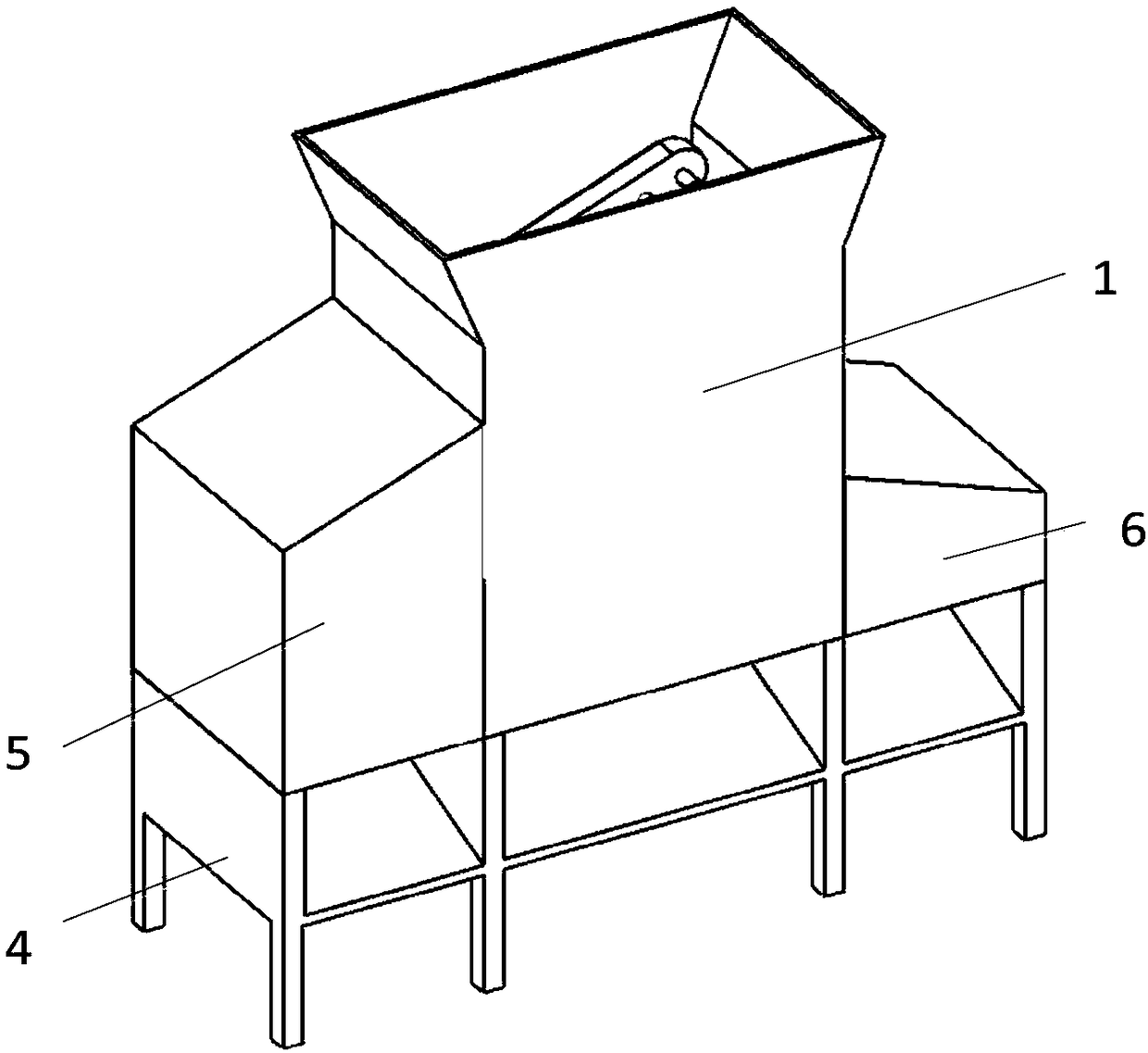

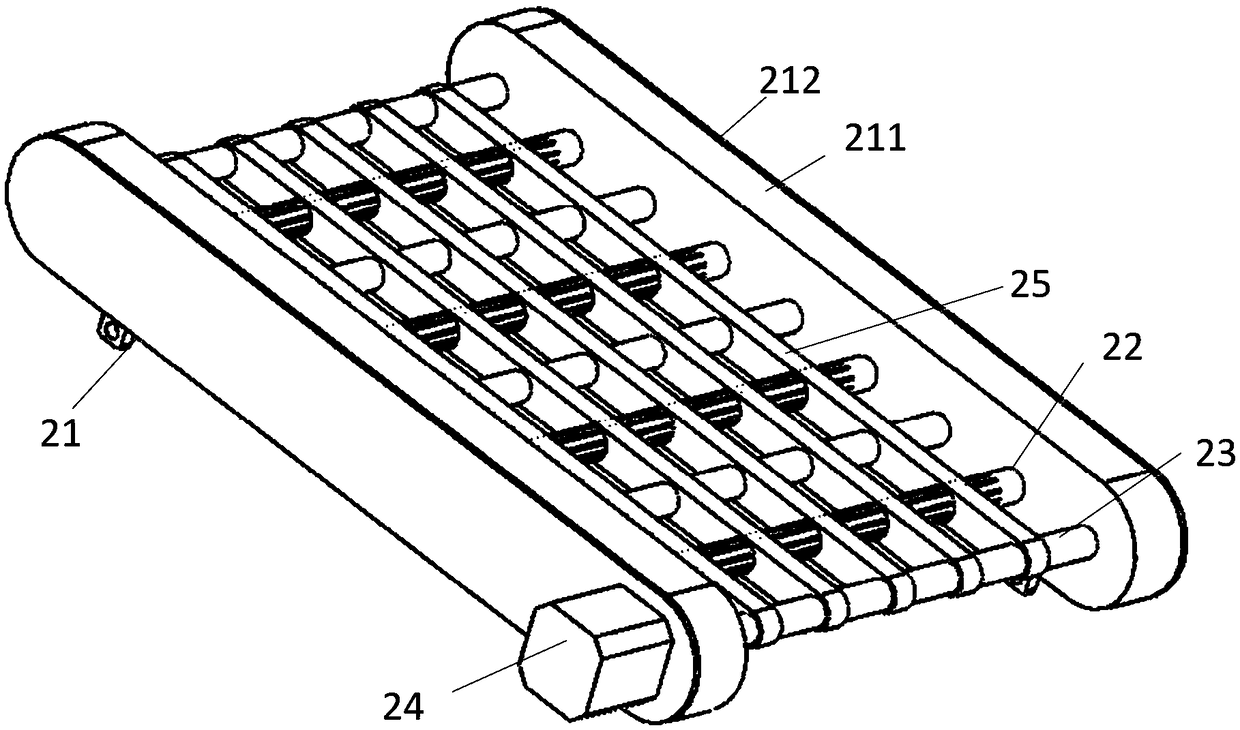

[0037] Such as figure 1 and figure 2As shown, a multi-stage ore screening device, the main box 1, the first screener 2, the second screener 3, the discharge frame 4, the first box 5 and the second box 6; the main box The body 1 is in the shape of a square cylinder with upper and lower openings, and its upper part is an upward trumpet-shaped material inlet 11. The two opposite side walls are respectively arranged at the first outlet 12 and the second outlet 13. The first outlet 12 is located higher than the second outlet 13. ; The first sieve 2 is fixed in the main box 1 and is located at the top of the main box 1, it is inclined, and its lower end is towards the first outlet 12; the second sieve 3 is fixed in the main box Inside and located at the lower part of the main box 1, it is located directly below the first sieve 2; it is inclined, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com