Noise reduction device and gas water heater

A technology of noise reduction and inner peripheral wall, which is applied to fluid heaters, components of pumping devices for elastic fluids, machines/engines, etc., and can solve problems such as poor noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

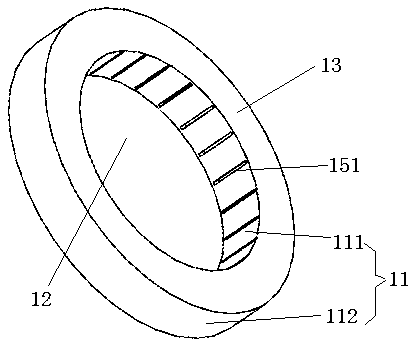

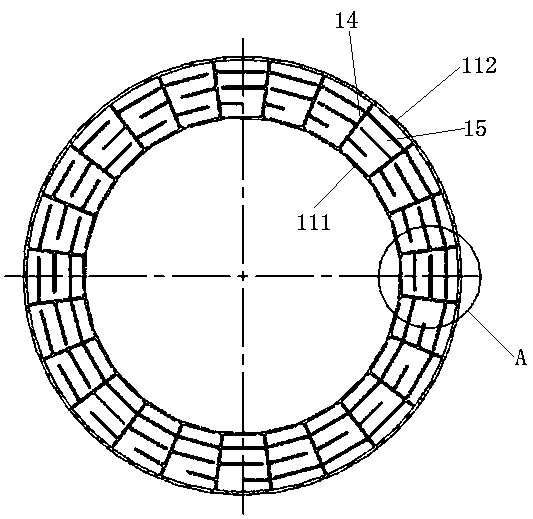

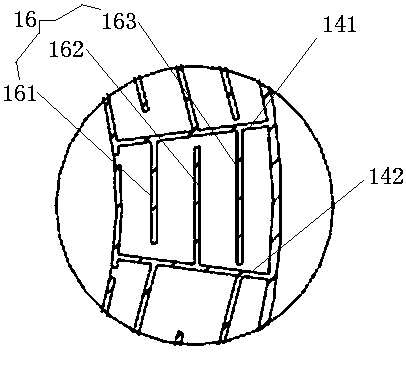

[0026] Embodiment 1, this embodiment proposes a noise reduction device, such as Figure 1-Figure 3 As shown, it includes a barrel-shaped body with an open end that is connected and surrounded by a peripheral wall 11 and a bottom wall 12. The peripheral wall 11 includes an inner peripheral wall 111 and an outer peripheral wall 112. There is a gap between the inner peripheral wall 111 and the outer peripheral wall 112. The inner peripheral wall 111 and the outer peripheral wall One end of the wall 112 is sealed and connected to the bottom wall 12, and the other end is connected through the connecting panel 13. A closed cavity is formed between the bottom wall 12, the inner peripheral wall 111, the outer peripheral wall 112 and the connecting panel 13, and the cavity is separated by a partition 14. Several sound-absorbing cavities 15 are formed, and the sound inlets 151 of the sound-absorbing chambers 15 are opened on the inner peripheral wall 111 . The peripheral wall 11 can be ...

Embodiment 2

[0040] Embodiment two, this embodiment proposes a kind of gas water heater at the same time, as Figure 5-Figure 7 As shown, it includes a housing 21 and a fan 22 arranged in the housing 21. The housing 21 is provided with an air inlet 23 opposite to the inlet of the fan 22. The top of the housing 21 is provided with a smoke pipe through which the smoke pipe 24 passes. hole 25, the housing 21 is provided with a noise reduction device 1, such as figure 1 As shown, the noise reduction device 1 includes a barrel-shaped body with one end open and surrounded by a peripheral wall 11 and a bottom wall 12. The peripheral wall 11 includes an inner peripheral wall 111 and an outer peripheral wall 112. There is a gap between the inner peripheral wall 111 and the outer peripheral wall 112. One end of the peripheral wall 111 and the outer peripheral wall 112 is sealed and connected to the bottom wall 12, and the other end is connected through the connecting panel 13. A closed cavity is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com