Low-noise silencer

A muffler and muffler pipe technology, which is applied to instruments, sounding equipment, chemical instruments and methods, etc., can solve the problems of reducing the working efficiency of the muffler, the muffler's poor muffler effect, and the muffler being easy to block the muffler. Blockage, not easy to block, the effect of ensuring the elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

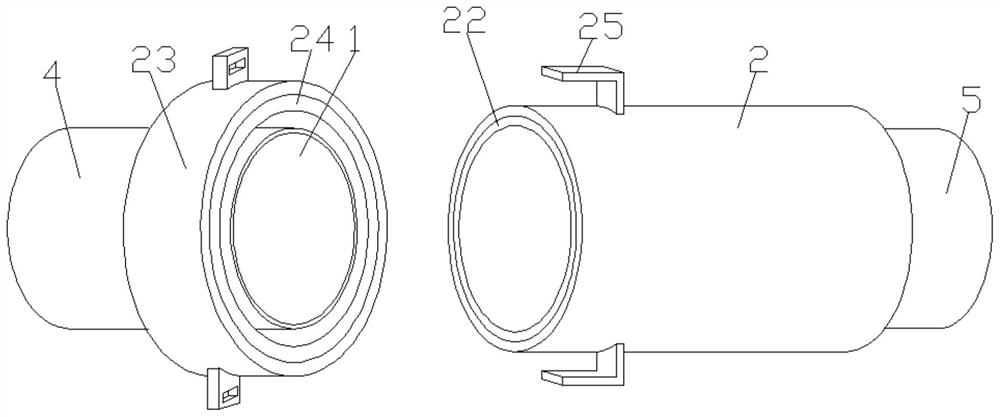

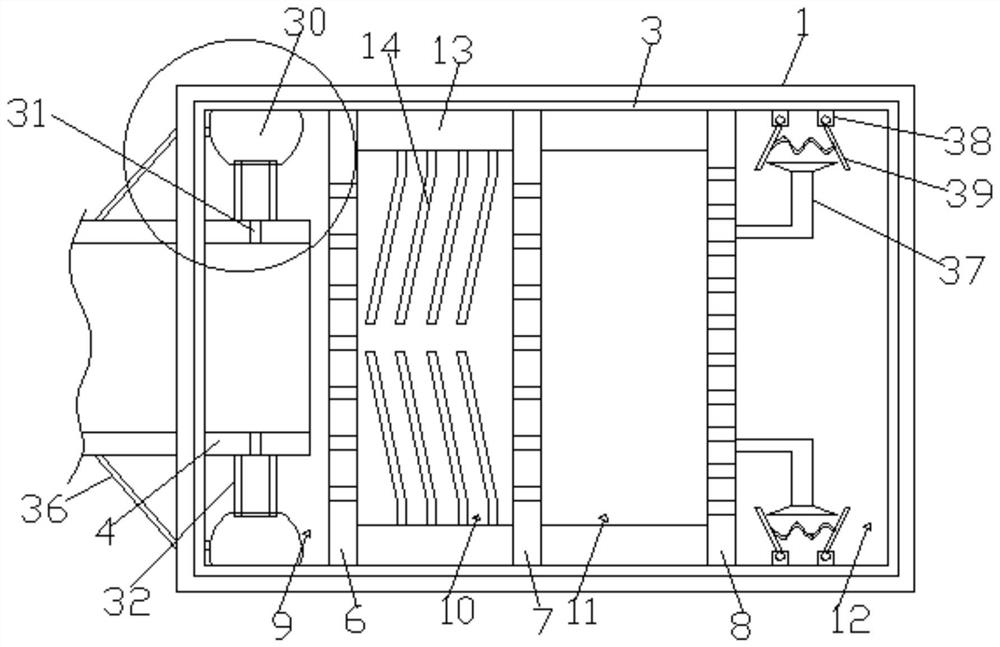

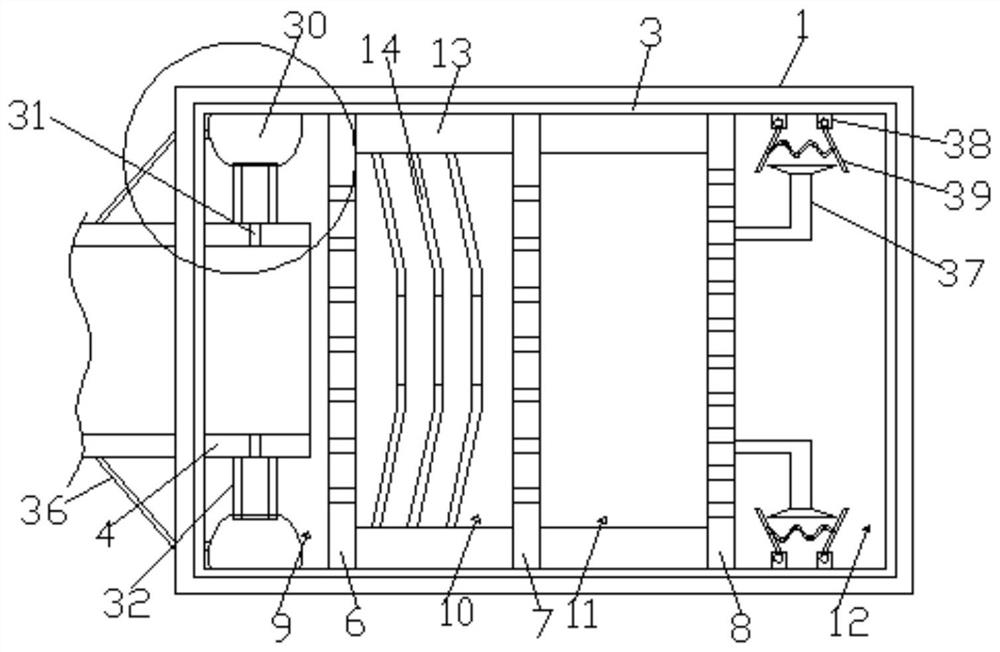

[0034] see Figure 1-8 , a low-noise muffler according to an embodiment of the present invention, comprising a circular first muffler pipe 1 and a circular second muffler pipe 2, the diameter of the first muffler pipe 1 is smaller than the diameter of the second muffler pipe 2 , and the first silencing pipe 1 and the second silencing pipe 2 are connected by installing a sealing mechanism, and the inner walls of the first silencing pipe 1 and the second silencing pipe 2 are provided with first sound-absorbing cotton 3. An inlet pipe 4 is installed on the first muffler pipe 1, an outlet pipe 5 is installed on the second muffler pipe 2, and a first muffler plate 6 with a sound hole is provided inside the first muffler pipe 1 , the second silencing plate 7 and the third silencing plate 8, the inside of the first silencing pipe 1 is divided into the first silencing chamber 9, the first silencing chamber 9 and the third silencing plate 8 by the first silencing plate 6, the second si...

Embodiment 2

[0036] see Figure 1-5 , the sound-absorbing board 13 includes an upper noise reduction board 26, a porous foam board 27 and a noise reduction board 28, and the upper noise reduction board 26, the porous foam board 27 and the noise reduction board 28 are formed as a molding , the upper noise reduction plate 26 and the noise reduction plate 28 are provided with a secondary sound hole, and the upper noise reduction plate 26 and the noise reduction plate 28 are both set in a cavity shape. Both the upper noise reduction board 26 and the noise reduction board 28 are provided with a cross-shaped hollow sound insulation column 29, the inner wall of the hollow sound insulation column 29 is provided with a sound insulation cotton block, and the first noise reduction mechanism includes a The sound insulation cover 30 on the inner wall of the first muffler cavity 9, the sound insulation cover 30, the inlet pipe 4 is provided with an air inlet 31, and the outer wall of the inlet pipe 4 is...

Embodiment 3

[0039] see Figure 5 and Figure 7 , the inside of the second muffler pipe 2 is provided with several sound insulation boards 40, one of the sound insulation boards 40 is provided with a flow equalizer 41, and the inside of the sound insulation plate 40 located on the side of the flow equalizer 41 is filled with Catalyst layer 42, another sound insulation plate 40 is filled with activated carbon mesh 43, the filter plate 15 includes a circular plate 44 equal to the inner diameter of the first muffler pipe 1, and the middle part of the circular plate 44 is embedded There is a filter screen, the outer surface of the bottom of the inlet pipe 4 is provided with a circular arc 45, and the bottom of the circular plate 44 is fixed with a circular arc 46 that matches the circular arc 45. A mounting piece 47 is fixedly arranged on the outer surface wall of the circular arc plate 46, and a sealing gasket 48 is arranged on the outer wall of the circular arc plate 46, and the sealing gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com