Splashing and air cooling combined condenser room with anti-frosting fan blades

A condenser and anti-frost technology, applied in ventilation systems, space heating and ventilation, space heating and ventilation details, etc., can solve the problem of increasing evaporative heat dissipation, increasing evaporation area, and evaporation of ring-shaped refrigerant liquid pipes Less heat dissipation and other issues, to achieve the effect of preventing energy consumption, saving energy consumption, and increasing the evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

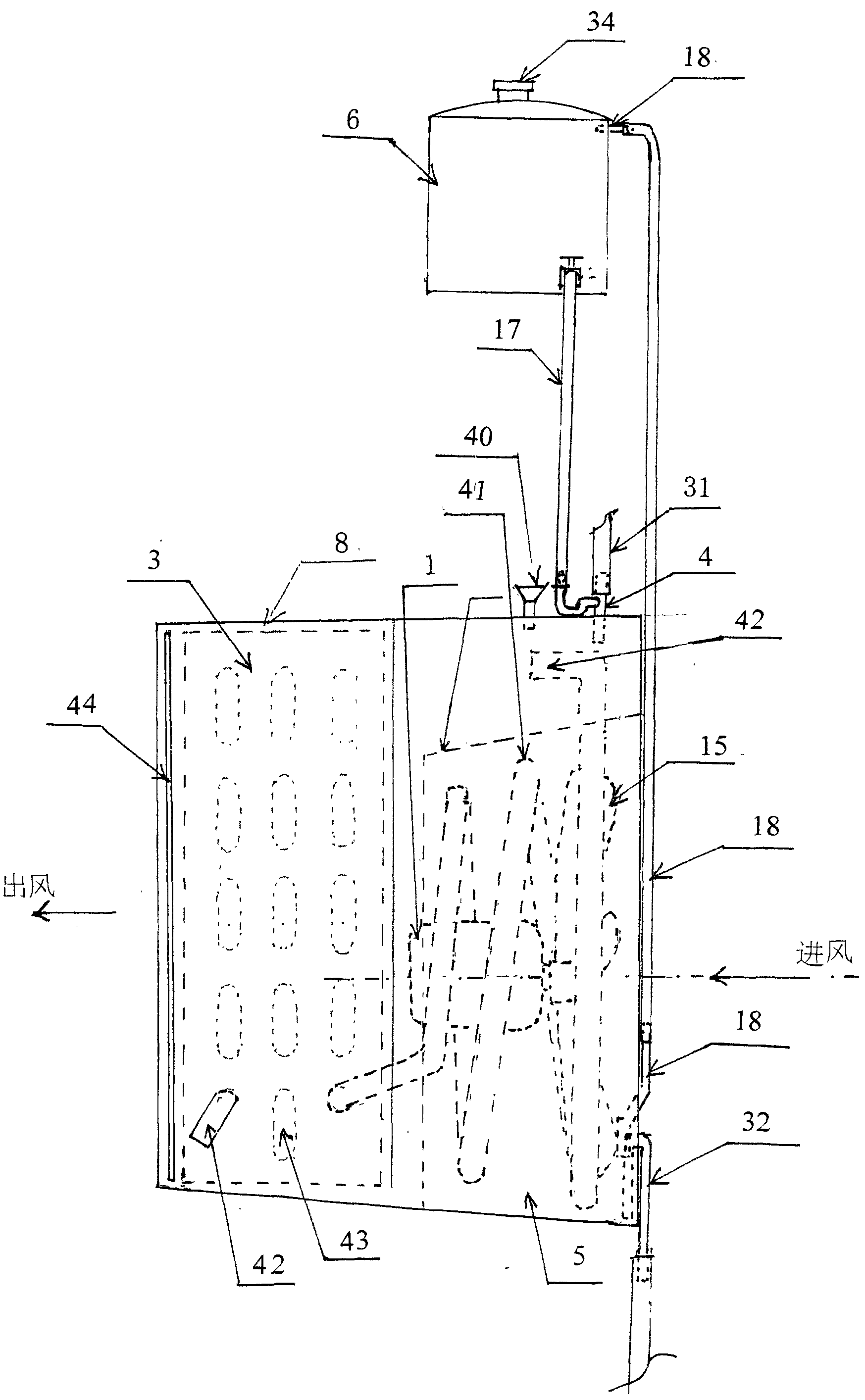

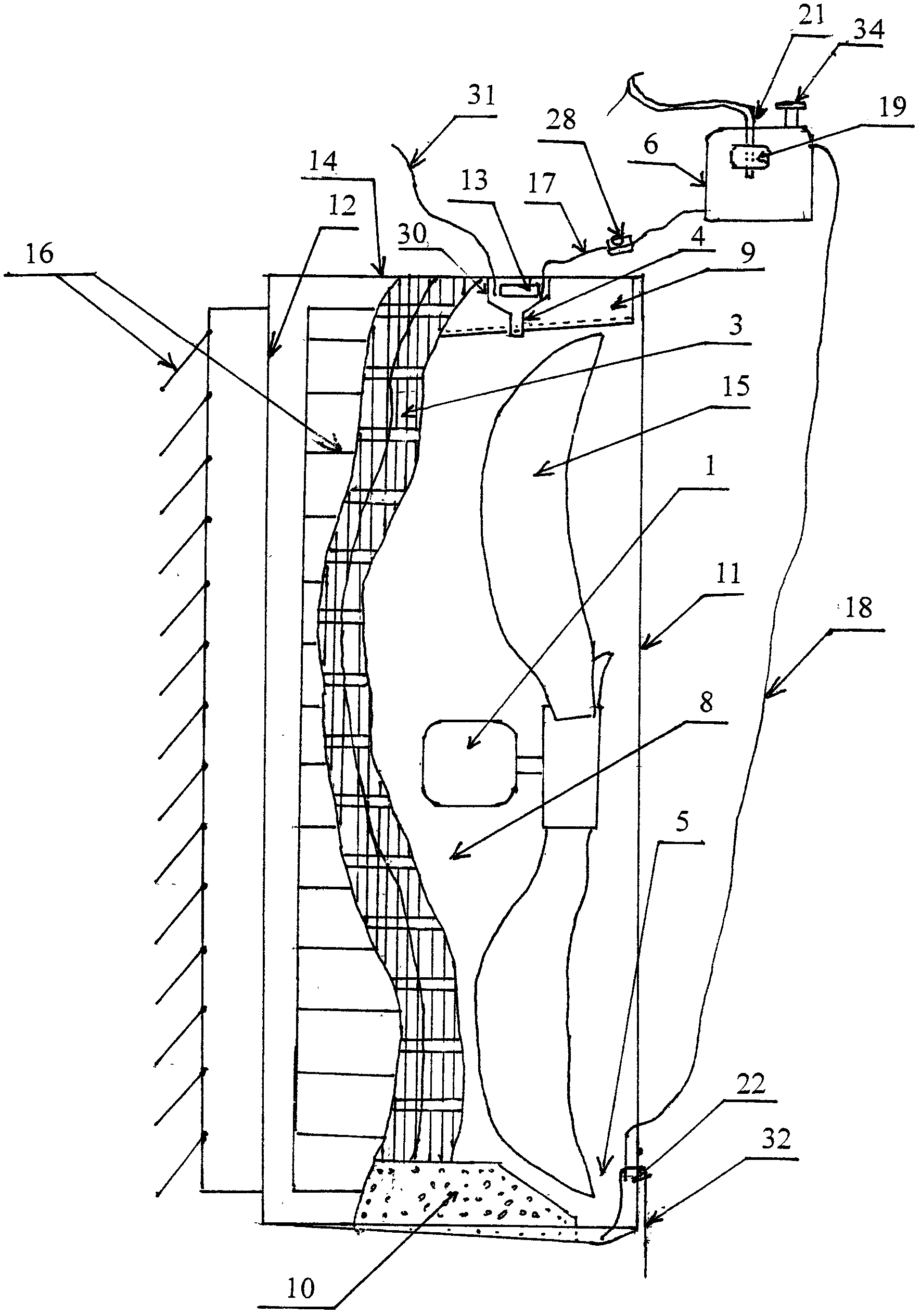

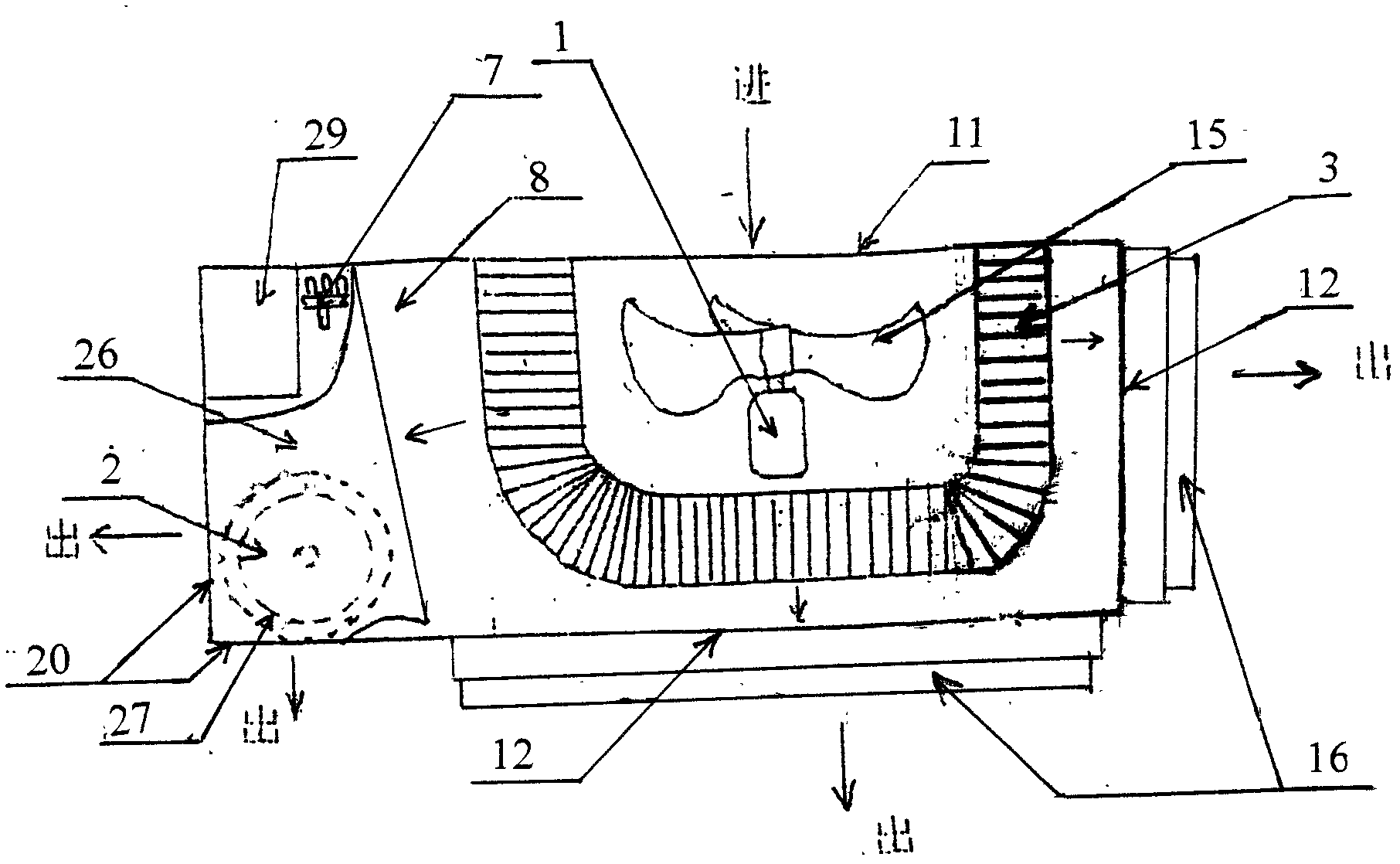

[0030] Example 1: figure 2 It is a schematic diagram of the structure of the anti-frost wind blade splash water air-cooled composite condenser chamber. The condenser chamber (8) is provided with a condenser (3) composed of finned refrigerant liquid tube groups, and the fan (1) is arranged inside the condenser (3). A cooling air inlet (11) is provided on the surrounding wall of the condenser chamber (8) on the front side of the fan blade (15), and an air outlet (12) is provided on the surrounding wall of the condenser chamber outside the condenser (3), and the air outlet (12) The outer side is provided with an outwardly blowing type self-weight closing louver (16), and the inner side of the corner of the other end of the condenser (3) outside the condenser room (8) is provided with a compressor (2), and the side condenser room of the compressor (2) ( 8) There are heating air inlets (20) on the two side walls of the corner of the surrounding wall, and a drip pipe (4) is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com