Multi-roll oil removal machine with built-in blowing and suction devices and strip oil removal method

A technology of suction device and degreasing machine, used in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of increasing the difficulty of strip annealing treatment, high noise of compressed air purging, slippage or dislocation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

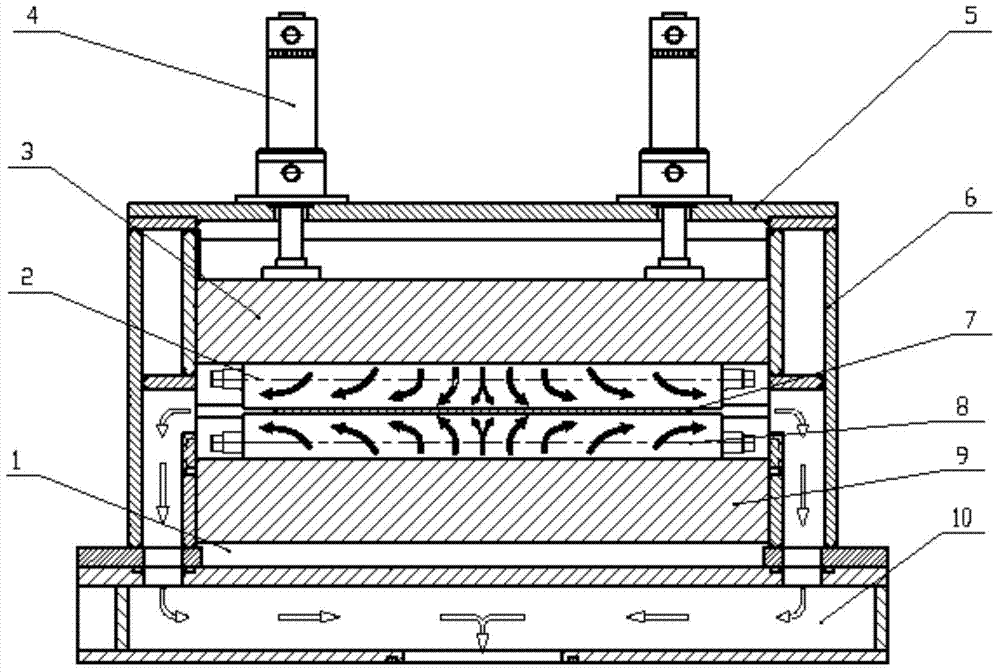

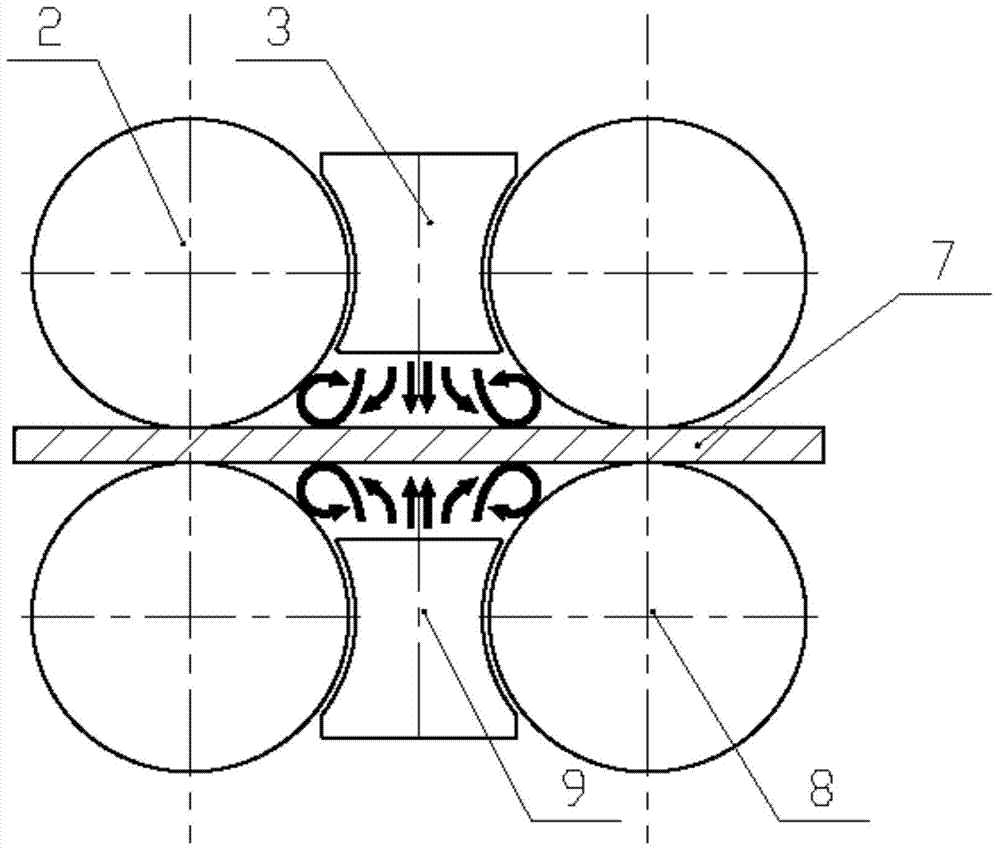

[0026] Such as figure 1 , 2 As shown, a multi-roll degreaser with built-in purging and suction devices includes a frame, multiple degreasing rollers, a purging device, a suction device and a sewage collection system. A plurality of degreasing rollers are all installed in the frame 1, and a plurality of degreasing rollers are arranged up and down the strip material 7, and are divided into an upper degreasing roller 2 and a lower degreasing roller 8 with the strip material 7 as a boundary.

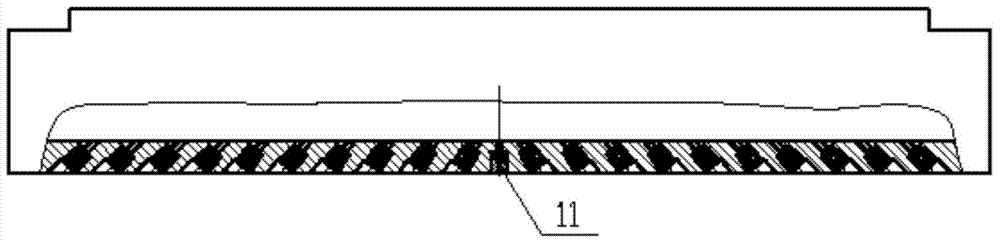

[0027] There is a purging device between the upper degreasing rollers and between the lower degreasing rollers. The purging device is in close contact with the two adjacent degreasing rollers. The upper degreasing roller and the lower degreasing roller correspond to the strip. The lower two pairs of degreasing rollers are in contact with the strip to form a closed chamber composed of the strip, degreasing rollers, purging device and frame. The suction device communicates with the closed ca...

Embodiment 2

[0042] The height of the degreasing roller is changed by the lifting device so that the upper and lower degreasing rollers clamp the strip to form a closed cavity surrounded by the strip, the degreasing roller, the purging device between the degreasing rollers and the frame. Use the purging device to purge the residual process lubricating liquid on the surface of the strip with compressed air at high pressure and low flow to form mist, and then suck it away through the suction device with low pressure and high flow. The strip moves between the upper and lower degreasing rollers, and the remaining process lubricating fluid on the strip is purged and degreased section by section, and then the degreasing of the entire strip is completed.

[0043] In this embodiment, a strip degreasing method is implemented on a multi-roll degreasing machine with built-in purge and suction devices as described in Embodiment 1, and the upper and lower parts are moved by a plurality of lifting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com