Manufacturing method of automobile muffler and noise elimination device

An automobile muffler and the technology of its manufacturing method are applied in the direction of mufflers, machines/engines, engine components, etc., which can solve problems such as large noise radiation, and achieve the effects of arc stability, noise reduction, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

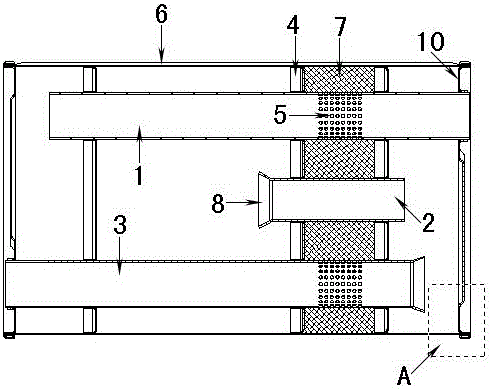

[0033] Such as figure 1 As shown, the muffler includes a shell 6 , an end cover 10 and a core assembly, and the core assembly includes a buffer pipe 2 , an intake buffer pipe 1 , an exhaust buffer pipe 3 and a separator 4 . The buffer pipe 2, the intake buffer pipe 1 and the exhaust buffer pipe 3 are provided with a partition 4 and a sound-absorbing cotton 7, and at the exhaust end of the intake buffer pipe 1 and the exhaust end of the exhaust buffer pipe 3, another A partition 4 is provided. In order to allow the gas discharged from the exhaust hole 5 at the exhaust end of the intake buffer pipe 1 to flow well in the housing 6 , each partition 4 is also provided with an exhaust hole 5 .

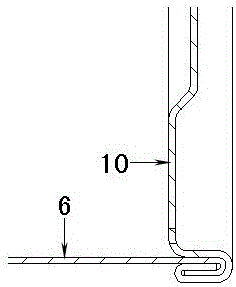

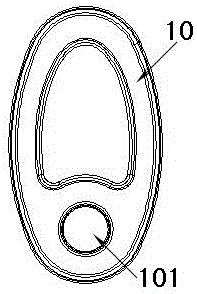

[0034] Such as figure 1 , figure 2 with image 3 As shown, the end caps 10 are installed at both ends of the housing 6, and the end caps 10 are aligned with the edges of the housing 6 and tightly attached, and the edges of the end caps 10 and the housing 6 are clamped and bent for hemmi...

Embodiment 2

[0046] Such as Figure 4 As shown, the muffler includes a shell 6 , an end cover 10 and a core assembly, and the core assembly includes a buffer pipe 2 , an intake buffer pipe 1 , an exhaust buffer pipe 3 and a separator 4 . Weld and fix the buffer pipe plug 9 on the exhaust end of the intake buffer pipe 1, wrap the sound-absorbing cotton 7 on the outside of the buffer pipe 2, the intake buffer pipe 1 and the exhaust buffer pipe 3, and let the sound-absorbing cotton 7 and both sides The partitions 4 are tightly attached so that there is no gap between the sound-absorbing cotton 7 and the partitions 4 on both sides. In order to allow the gas discharged from the exhaust hole 5 at the exhaust end of the intake buffer pipe 1 to flow well in the housing 6 , each partition 4 is also provided with an exhaust hole 5 .

[0047] The buffer pipe 2 is arranged between the intake buffer pipe 1 and the exhaust buffer pipe 3, the middle part of the intake buffer pipe 1 and the exhaust end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com