Mechanical device capable of achieving noise insulation during cutting

A kind of mechanical equipment and cavity technology, which is applied in the field of furniture production equipment, can solve the problems of loud noise, sawdust splashing, weakening transmission, etc., and achieve the effect of simple structure and protecting physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

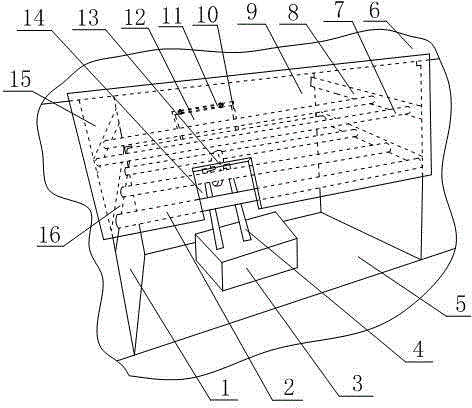

[0017] like figure 1 As shown, the mechanical equipment capable of sound insulation during cutting includes a support system with a cavity inside, and the cavity penetrates both ends of the support system, and the two ends of the support system are respectively provided with sealing covers, and the top of the sealing cover is set at Above the top of the cavity, there is a gap between the bottom end of the sealing cover and the bottom end of the cavity, and the sealing cover is respectively provided with a feed port 14 and a discharge port 10 communicating with the cavity, and a feed port 14 and a discharge port 10 Connected with the bottom of the corresponding sealing cover respectively, a discharge door 12 is arranged in the discharge port 10, a connecting ring is arranged between the discharge door 12 and the top of the discharge port 10, and the connecting ring is fixed to the top of the discharge port 10, A rotating shaft 11 is arranged in the connecting ring, and the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com